Table of Contents

1. FUNDAMENTALS ABOUT THE SYSTEM ..................................................................1

1.1 Features of the TTP-243 Series .................................................................................1

1.2 Model Naming Syntax.................................................................................................1

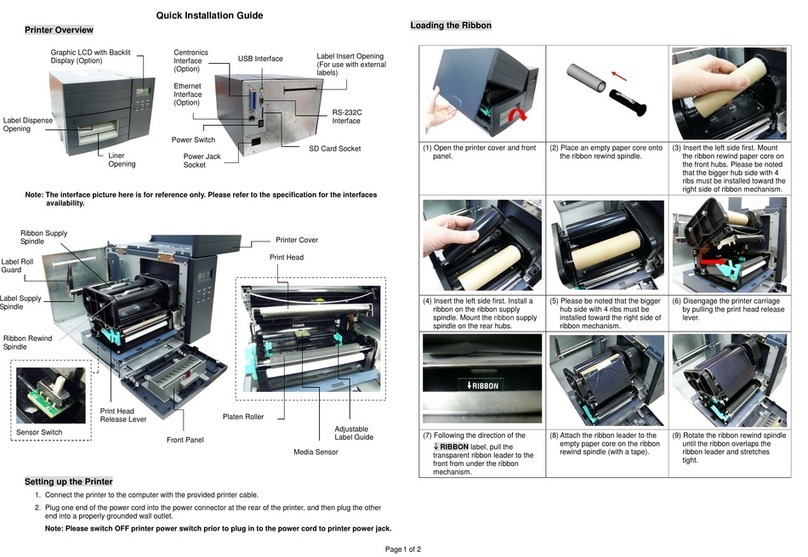

1.3 Overview ....................................................................................................................2

1.3.1 Front View...........................................................................................................2

1.3.2 Rear View...........................................................................................................3

1.4 Basic Specifications....................................................................................................4

1.5 Effective Print Area.....................................................................................................6

1.6 Available Bar Codes...................................................................................................6

1.7 Various Sensors.........................................................................................................7

2. SUPPLY SPECIFICATIONS.............................................................................................9

2.1 Types of Paper...........................................................................................................9

2.2 Specifications.............................................................................................................9

2.3 Ribbon Sizes and Shapes ........................................................................................11

3. ELECTRONICS ..............................................................................................................12

3.1 Summary of Board Connectors ................................................................................12

3.2 Pin Configuration......................................................................................................14

4. MECHANISM..................................................................................................................16

4.1 Mainboard Replacement...........................................................................................16

4.2 Cutter Installation (Option / Not available for TTP-243E Pro model).........................20

4.3 Print Head Replacement ..........................................................................................21

4.4 DC Motor Replacement............................................................................................23

4.5 Ribbon Rewind Spindle Encoder Replacement ........................................................24

4.6 Felt Fabric Replacement ..........................................................................................25

4.7 Stepping Motor Replacement...................................................................................27

4.8 Black Mark Sensor / Gap Sensor (Receiver) Replacement ......................................28

4.9 Ribbon Sensor (Receiver) Replacement...................................................................29

4.10 Ribbon Sensor (Transmitter) / Gap Sensor (Transmitter) Replacement .................31