- iii -

Contents

1. Introduction......................................................................................................................................... 1

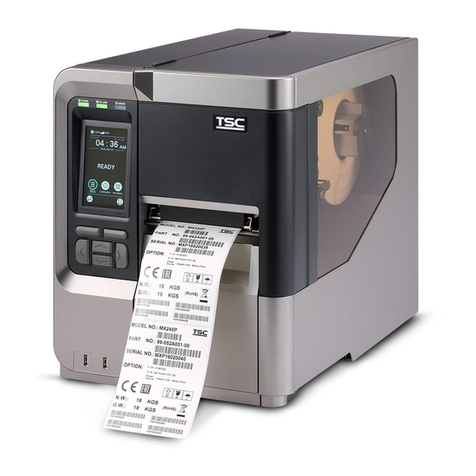

1.1 Product Introduction..................................................................................................................... 1

1.2 Product Features.......................................................................................................................... 2

1.2.1 Printer Standard Features................................................................................................ 2

1.2.2 Printer Optional Features................................................................................................. 3

1.3 General Specifications ................................................................................................................. 4

1.4 Print Specifications....................................................................................................................... 4

1.5 Media Specifications .................................................................................................................... 5

2. Operations Overview.......................................................................................................................... 6

2.1 Unpacking and Inspection............................................................................................................ 6

2.2 Printer Overview........................................................................................................................... 7

2.2.1 Front & rear........................................................................................................................ 7

2.2.2 Interior View....................................................................................................................... 8

2.3 LED and Button Function............................................................................................................. 9

2.3.1 LED Indication................................................................................................................... 9

2.3.2 Regular Button Function.................................................................................................. 9

3. Setup ................................................................................................................................................ 10

3.1 Setting up the Printer.................................................................................................................. 10

3.2 Loading the Media...................................................................................................................... 11

3.2.1 Loading the Roll Labels ................................................................................................. 11

3.2.2 Loading External Media.................................................................................................. 13

4. Power-on Utilities.............................................................................................................................. 15

4.1 Gap/Black Mark Sensor Calibration........................................................................................... 16

4.2 Gap/Black Mark Calibration, Self-test and Dump Mode ............................................................ 17

4.2.1 Self-test............................................................................................................................ 18

4.2.2 Dump mode ..................................................................................................................... 20

4.3 Printer Initialization..................................................................................................................... 21

4.4 Set Black Mark Sensor as Media Sensor and Calibrate the Black Mark Sensor..................... 22

4.5 Set Gap Sensor as Media Sensor and Calibrate the Gap Sensor........................................... 22

4.6 Skip AUTO.BAS........................................................................................................................ 23

5. Diagnostic Tool................................................................................................................................. 24

5.1 Start the Diagnostic Tool............................................................................................................ 24