Contents

1. Introduction..........................................................................................................1

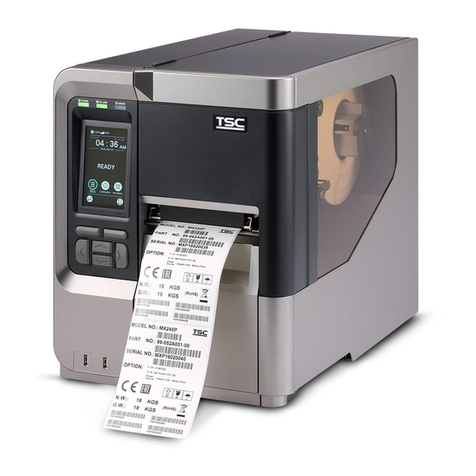

1.1 Product Introduction......................................................................................... 1

1.2 Product Features............................................................................................... 2

2. Operations Overview ...........................................................................................3

2.1 Unpacking and Inspection................................................................................ 3

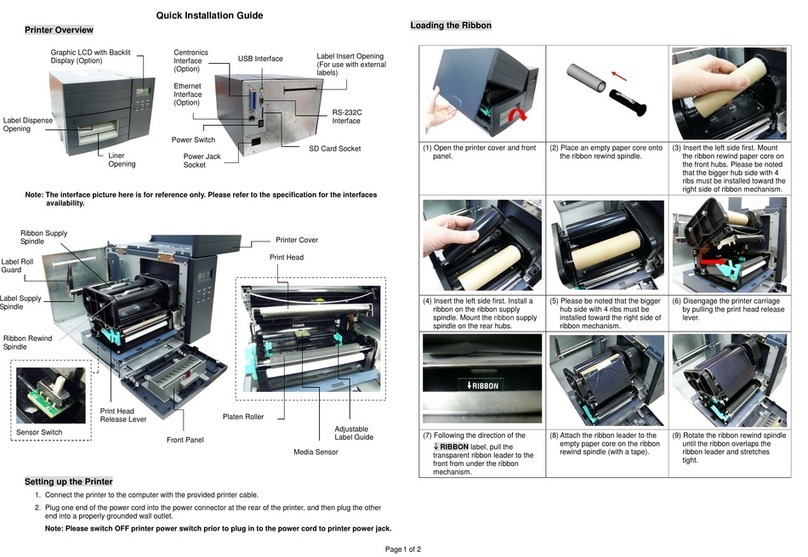

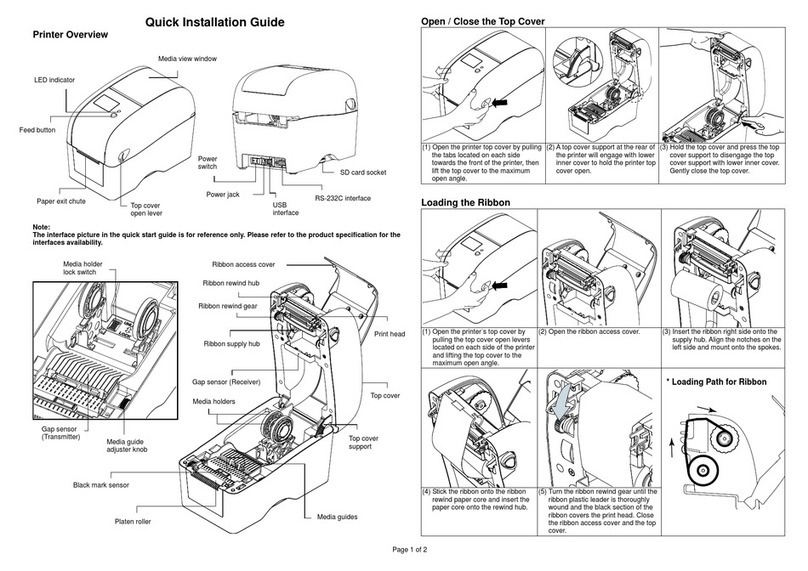

2.2 Printer Overview................................................................................................ 4

2.2.1 Front View............................................................................................... 4

2.2.2 Interior View............................................................................................ 5

2.2.3 Rear View ................................................................................................ 6

3. Setup.....................................................................................................................7

3.1 Setting up the Printer........................................................................................ 7

3.2 Loading the Ribbon........................................................................................... 8

3.3 Loading the Media........................................................................................... 11

3.3.1 Loading the Roll Labels ....................................................................... 11

4. LED and Button Functions ...............................................................................14

4.1 LED Indicator................................................................................................... 14

4.2 Regular Button Functions .............................................................................. 14

4.3 Power-on Utilities............................................................................................ 14

4.3.1 Gap/Black Mark Sensor Calibration .................................................... 15

4.3.2 Gap/Black Mark Calibration, Self-test and Dump Mode..................... 16

4.3.3 Printer Initialization .............................................................................. 19

4.3.4 Set Black Mark Sensor as Media Sensor and Calibrate the Black Mark

Sensor............................................................................................................ 20

4.3.5 Set Gap Sensor as Media Sensor and Calibrate the Gap Sensor...... 20

4.3.6 Skip AUTO.BAS .................................................................................... 21

5. Diagnostic Tool..................................................................................................22

5.1 Start the Diagnostic Tool................................................................................ 22

5.2 Printer Function .............................................................................................. 23

5.3 Calibrating Media Sensor by Diagnostic Tool................................................24

5.3.1 Auto Calibration.................................................................................... 24

6. Troubleshooting.................................................................................................25

6.1 Common Problems ......................................................................................... 25

7. Maintenance.......................................................................................................28

Revise History........................................................................................................30