Series TY-B — 80 and 115 K-factor

Conventional Sprinklers

Special Response, Standard Coverage

Worldwide

Contacts

www.tyco-fire.com

Page 1 of 4 FEBRUARY 2015 TFP663

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

General

Description

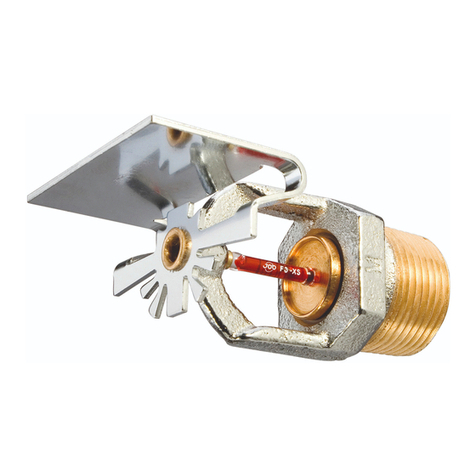

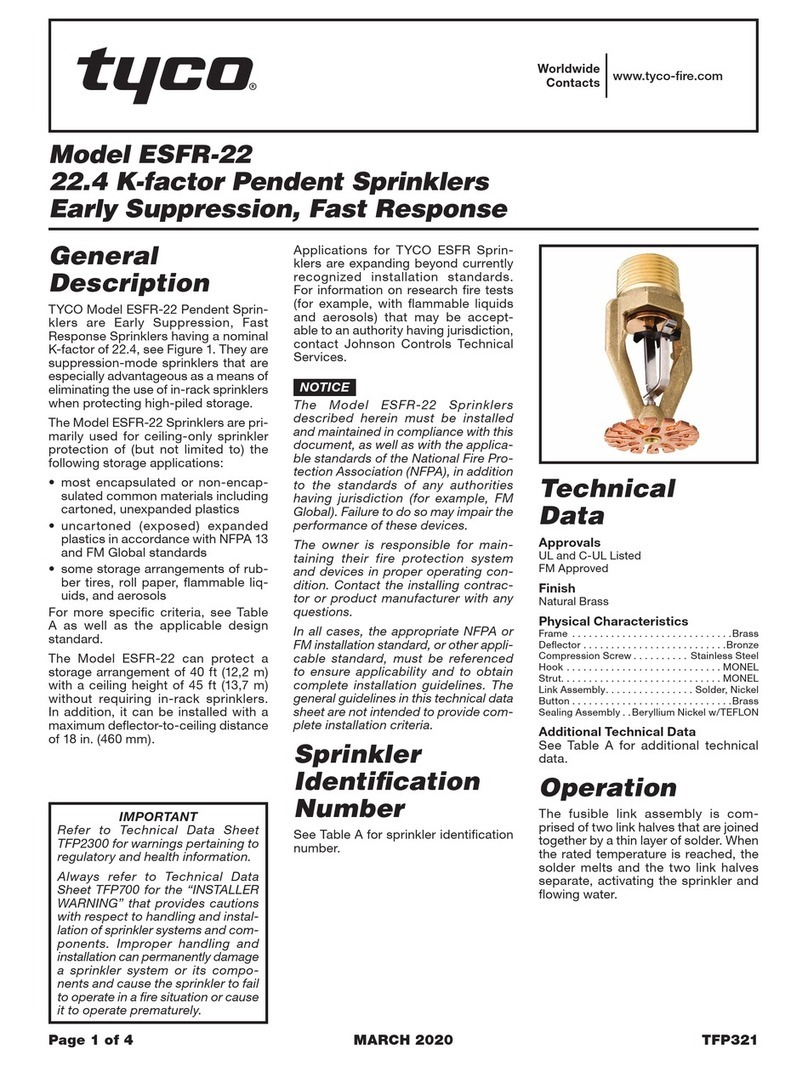

The Series TY-B, 80 and 115 K-factor,

Conventional Sprinklers described in

this data sheet are special response -

standard coverage, decorative 4 mm

glass bulb sprinklers designed for use

in accordance with the installation rules

recognized by the applicable Approval

agency (e.g., VdS). These sprinklers are

intended to be installed either pendent

or upright, and in either position, they

produce a spherical water discharge

pattern with approximately 50% of

the discharge directed upwards and

approximately 50% of the discharge

directed downwards.

NOTICE

The Series TY-B Sprinklers described

herein must be installed and maintained

in compliance with this document, as

well as with the applicable standards

recognized by the Approval agency, in

addition to the standards of any other

authorities having jurisdiction. Failure

to do so may impair the performance

of these devices.

The owner is responsible for maintain-

ing their fire protection system and

devices in proper operating condi-

tion. Contact the installing contrac-

tor or product manufacturer with any

questions.

Sprinkler

Identification

Numbers (SINs)

TY3641 – Conventional 80K

TY4641 – Conventional 115K

Technical

Data

Approvals

VdS Approved (CEA 4001)

Maximum Working Pressure

12,1 bar

Discharge Coefficient

K = 80 lpm/bar1/2

K = 115 lpm/bar1/2

Temperature Ratings

57°C, 68°C, 79°C, 93°C, and 141°C

Finishes

Refer to Table A.

Physical Characteristics

Frame ............................Bronze

Button...................... Brass/Copper

Sealing Assembly . . . . . . . . . . . . . . . . Beryllium

Nickel w/TEFLON

Bulb .............................. Glass

Compression Screw . . . . . . . . . . . . . . . . Bronze

Deector..........................Copper

Operation

The glass bulb contains a uid which

expands when exposed to heat. When

the rated temperature is reached, the

uid expands sufciently to shatter the

glass bulb, allowing the sprinkler to acti-

vate and water to ow.

Installation

The Series TY-B Sprinklers must

be installed in accordance with this

section.

General Instructions

Do not install any bulb type sprinkler

if the bulb is cracked or there is a loss

of liquid from the bulb. With the sprin-

kler held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1,6 mm for

the 57°C to 2,4 mm for the 141°C tem-

perature ratings.

A leak tight 1/2 inch NPT sprinkler joint

should be obtained with a torque of

9 to 19 Nm. A leak tight 3/4 inch NPT

sprinkler joint should be obtained with

a torque of 13 to 27 Nm. Higher levels

of torque may distort the sprinkler inlet

and cause leakage or impairment of the

sprinkler.