MAINTENANCE:

• Clean Rope Grab with water and mild soap. Wipe off with

clean dry cloth. Low pressure compressed air may be used.

• Lubricate with light oil such as WD-40. Use a small amount

of oil on pivot and roller bearing points. Wipe off excess oil

from body and surfaces of the rollers so that oil is not

transferred to the rope.

IN TALLATION AND U E:

• To open the US-5000C pivot the locking clip away from the

body then turn' locking screw Counter-clockwise till

disengaged then pivot open. Inspect as outlined above.

• Position Rope Grab with arrow pointing up (roller attached to

hinge pin will be pointed down)

• Insert the lifeline. Only 5/8" (15.875mm) dia. rope should be

used.. (See LIFELINE section following).

• Pivot the ring so that the gripper does not press against the

rope then close the unit around the rope.

• Tighten the locking screw. It should thread easily and tighten

against the Rope Grab body with both body parts touching.

Rotate the locking dip over the detent (dimple) into the,

notch in the body. It should move easily. and be held in the

locked position by a combination of the detent and bronze

thrust wash-er. Be sure the screw is tight and clip is fully in

the locked position.

• Test mobility: This Rope Grab was designed to function with

a. minimum of effort ove upward by pulling.up on the ring,

the Rope Grab should move easily upwards. ove

downward by lifting up on the ring enough-to release the

gripper and allow the weight of the unit to ' ove the Rope

Grab downwards. Repeat to ensure the freedom of

movement.

• Test the installation by pulling down sharply on the ring to

ensure that the mechanism locks onto the rope. Continued

on other side.

•

WARNING: WHEN IN U E, DO NOT REPO ITION / MOVE THE

UNIT BY HOLDING ON TO THE BODY OF THE ROPE GRAB. IF A

WORKER HOULD FALL WHILE HOLDING THE ,BODY OF THE

ROPE GRAB THEY MAY BE RE TRAINING THE LOCKING

MECHANI M, RENDERING IT UNABLE TO ARRE T THE FALL.

ERIOU INJURY COULD RE ULT. ee Diagrams 1 & 2.

• To assist the 'trailing' movement of the Rope Grab the

vertical life line should be held taught by attaching a 6 to 10

lb. weight or by securing the lifeline from below. The safest

method is determined by job site conditions and trained

personnel.

• Rope Grabs are designed for use in a one person fall arrester

restraint system with a maximum weight (person and

equipment) of 400 lbs.

• Anchor point should be capable of supporting a 5000 lb

(22.3kN) load and located directly above the user or twice

the intended load.

• Lanyards should be selected to meet the application with a

5000 lb (22.3kN) tensile strength on all components. ANSI

Z359.1 lanyard or twice the intended load. CSA Z259.2 - a

permanently attached 3 ft (0.6m) lanyard may be installed.

• Never allow rope or rope grab to contact any outside objects

during use. ake sure that your path is free and clear of

obstructions and hazards.

• Positioning the rope grab above user on the life line

minimizes falling distance.

• Calculate fall distance

• Avoid swing falls by working directly below the anchor point

whenever possible.

• If Rope Grab is subject to an arrest it should be removed

from service and discarded.

• After use, inspect as instructed above then clean and store.

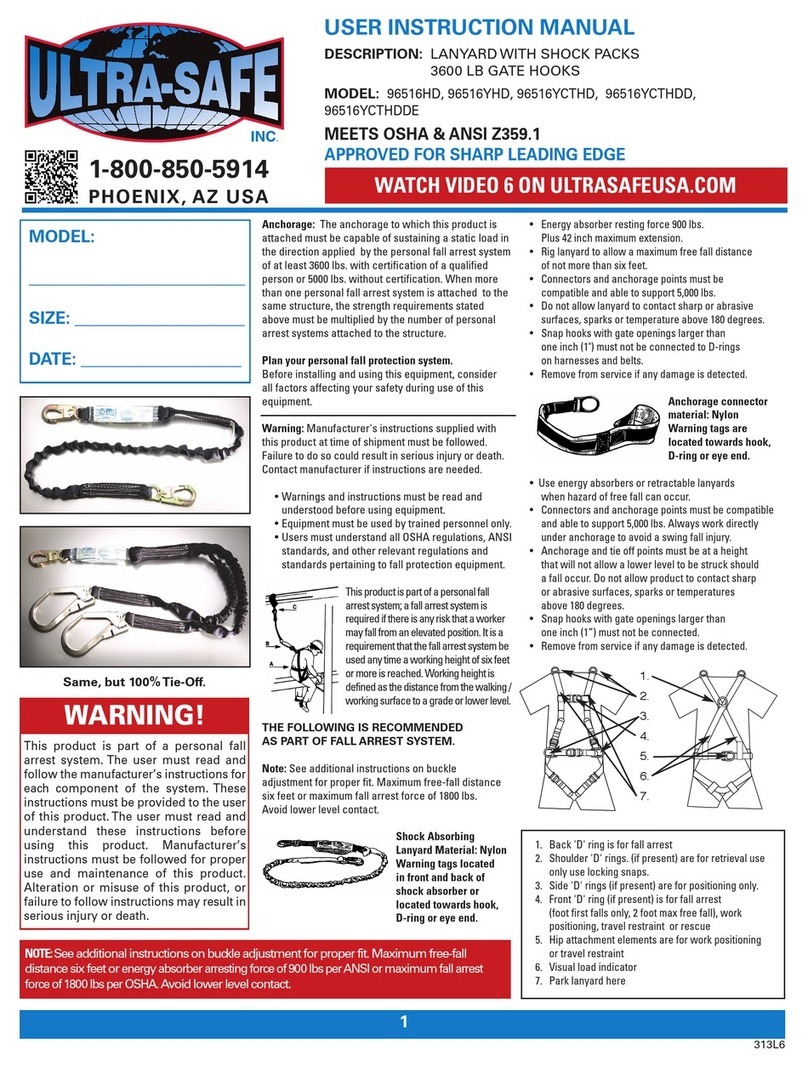

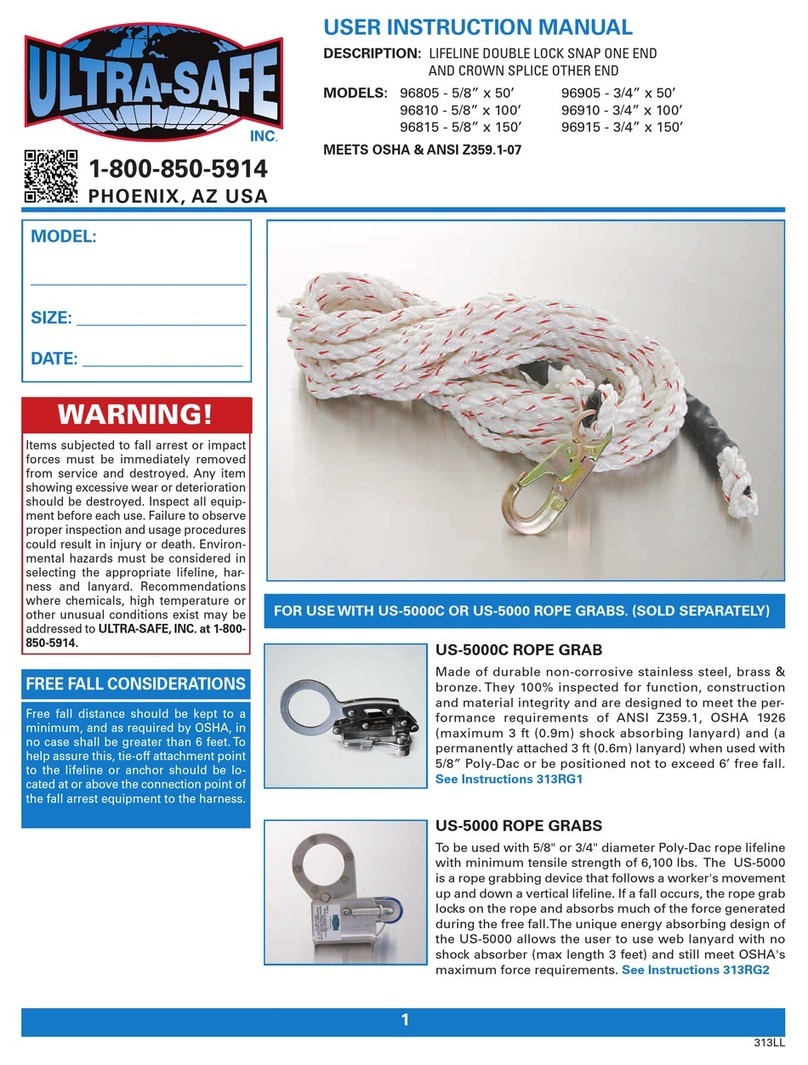

Diagram 1: Correct

repositioning of Rope Grab

Diagram 2: Incorrect

repositioning of Rope Grab

2