WARNING!

Thi product i part of a per onal fall

arre t y tem. The u er mu t read and

follow the manufacturer’ in truction

for each component of the y tem. The e

in truction mu t be provided to the u er

of thi product. The u er mu t read and

under tand the e in truction before

u ing thi product. Manufacturer’

in truction mu t be followed for proper

u e and maintenance of thi product.

Alteration or mi u e of thi product, or

failure to follow in truction may re ult

in eriou injury or death.

1

MODEL:

_________________________

_

SIZE: ____________________

DA E: __________________

_

An horage: The anchorage to which this product is

attached must be capable of sustaining a static load

in the direction applied by the personal fall arrest

system of at least 3600 lbs. with certification of a

qualified person or 5000 lbs. without certification. When

more than one personal fall arrest system is attached to

the same structure, the strength requirements stated

above must be multiplied by the number of personal

arrest systems attached to the structure.

Plan your personal fall prote tion system.

Before installing and using this equipment,

consider all factors affecting your safety during

use of this equipment.

Warning: anufacturer's instructions supplied with

this product at time of shipment must be followed.

Failure to do so could result in serious injury or death.

Contact manufacturer if instructions are needed.

• Warnings and instructions must be read and

understood before using equipment.

• Equipment must be used by trained personnel

only.

• Users must understand all OSHA regulations, ANSI

standards, and other relevant regulations and

standards pertaining to fall protection equipment.

Same, but 100% ie-Off.

313L2

USER INS RUC ION MANUAL

DESCRIP ION: IN-LINE SHOCK ABSORBING LANYARD 3600 LB GATES

MODEL:

UT-96516, UT-96516Y, UT-96516YSR, UTT-96516, UTT-96516Y, UTT-96516YSR,

UTT-96516YCT, UT-96516LY, UT-96516LYSR, UT-96516LYCA, UTT-96516LY, UT-96516LYCA,

UTT-96516LYSR, UTT-96516AA, UTT-96516YAA, UTT-96516YACA, UT-96516YSRD,

UT-96516LYSRDE, UTT-96516YSRD, UT-96516LYSRDE

MEE S OSHA & ANSI Z359.1 | APPROVED FOR LEADING EDGE

1-800-850-5914

PHOENIX, AZ USA WATCH VIDEO 6 ON ULTRASAFEUSA.COM

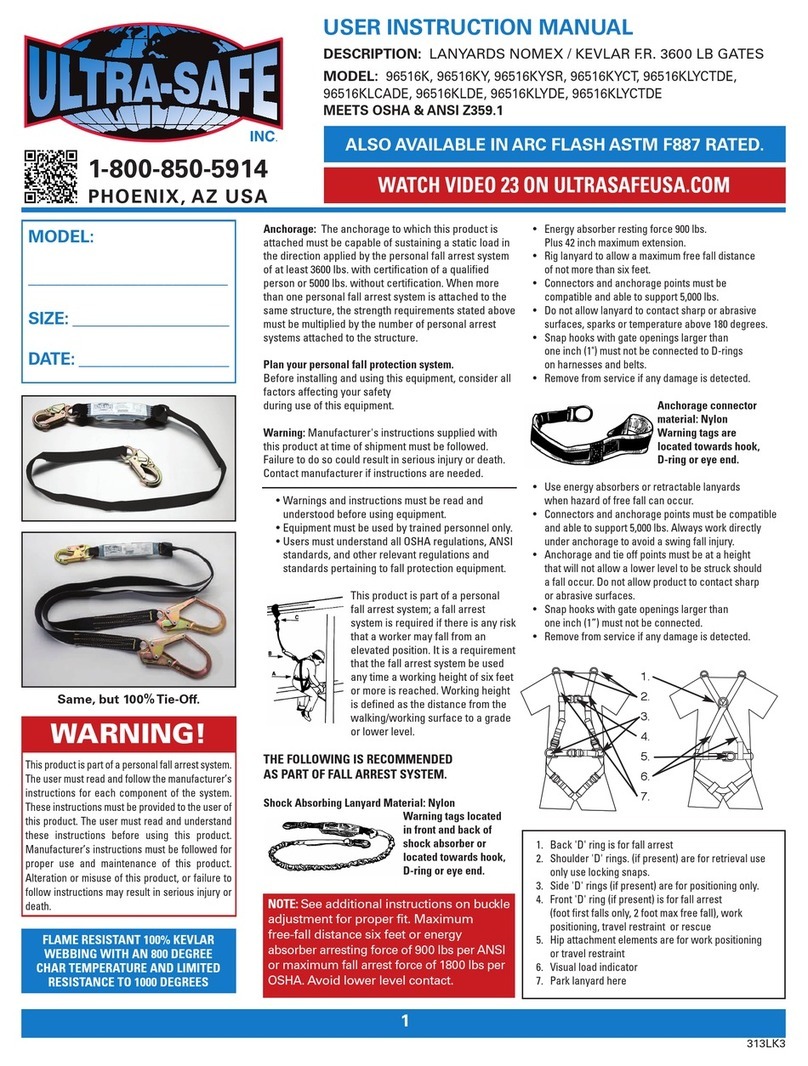

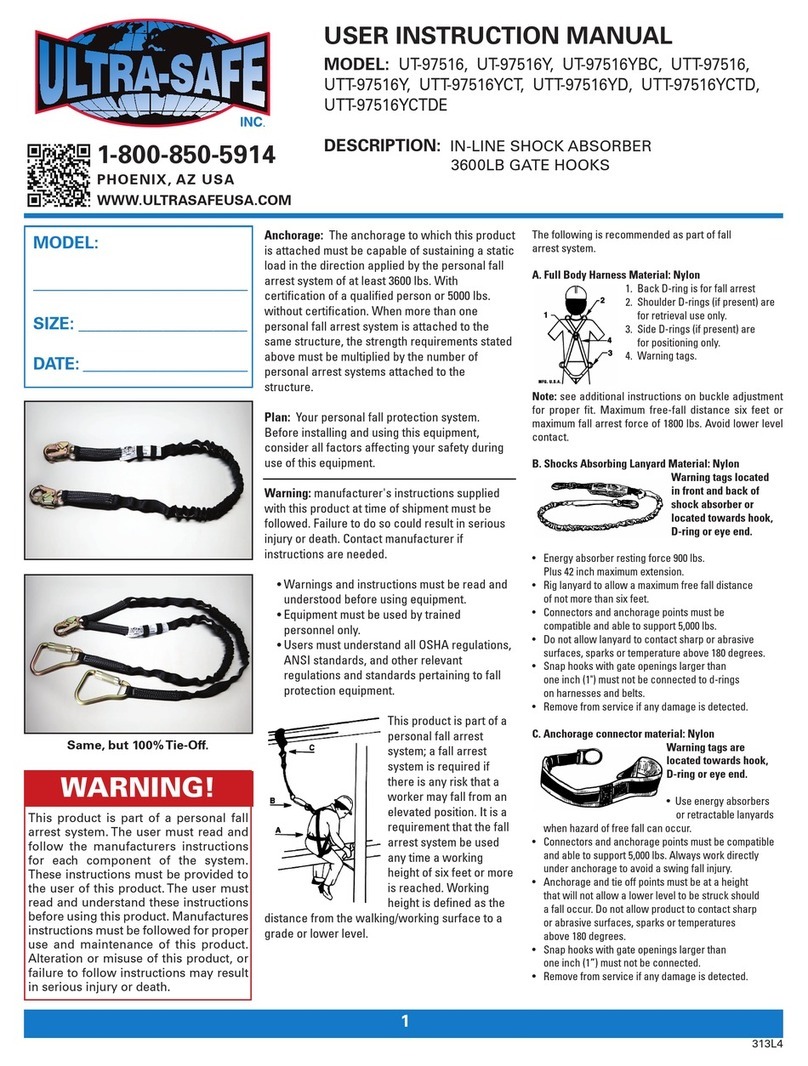

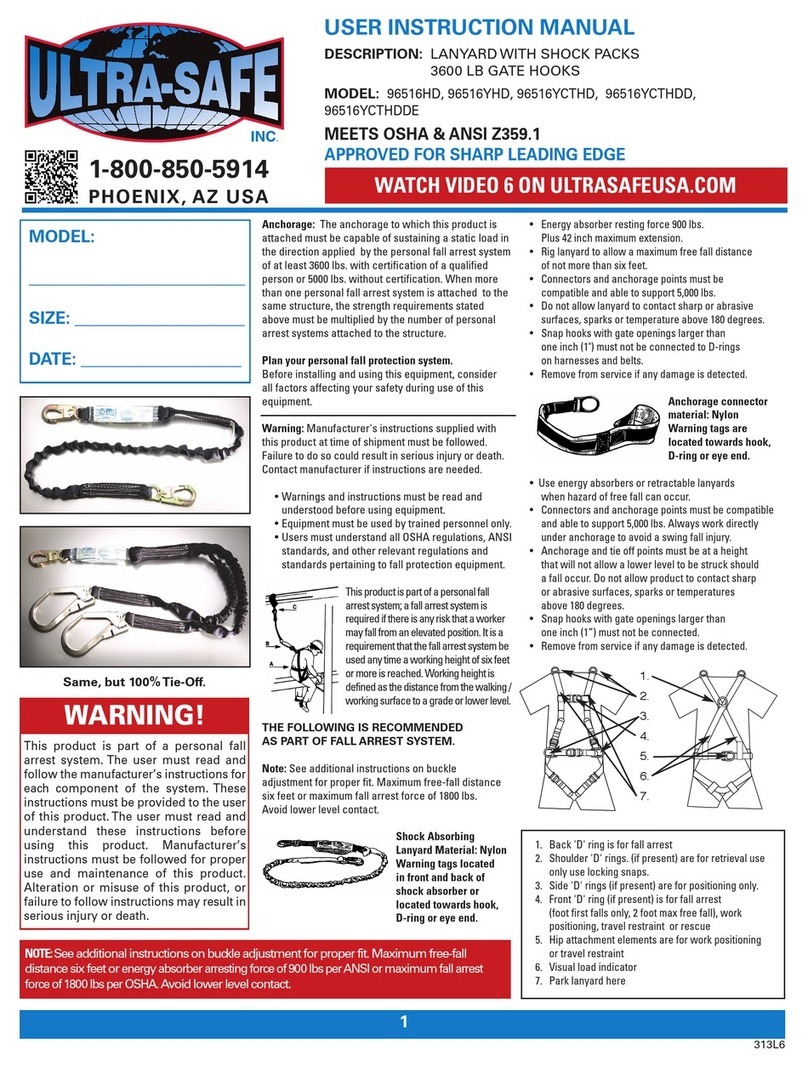

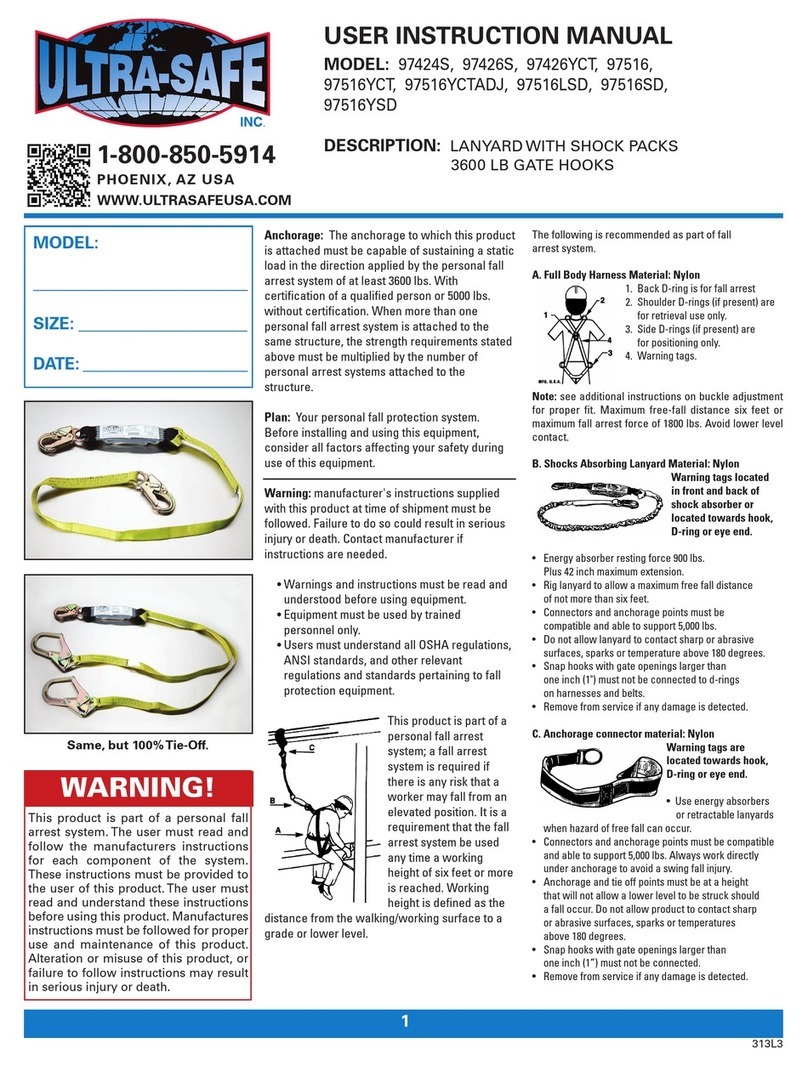

Sho k Absorbing Lanyard

Material: Polyester

Warning tags lo ated

in front and ba k of sho k

absorber or lo ated towards

hook, D-ring or eye end.

• Energy absorber resting force 900 lbs.

Plus 42 inch maximum extension.

• Rig lanyard to allow a maximum free fall distance

of not more than six feet or max impact of 1,800 lbs.

• Connectors and anchorage points must be

compatible and able to support 5,000 lbs.

• Do not allow lanyard to contact sharp or abrasive

surfaces, sparks or temperature above 180 degrees.

• Snap hooks with gate openings larger than

one inch (1") must not be connected to D-rings

on harnesses and belts.

• Remove from service if any damage is detected.

An horage onne tor

material: Nylon

Warning tags are

lo ated towards hook,

D-ring or eye end.

•

Use energy absorbers or retractable lanyards

when hazard of free fall can occur.

• Connectors and anchorage points must be compatible

and able to support 5,000 lbs. Always work directly

under anchorage to avoid a swing fall injury.

• Anchorage and tie off points must be at a height

that will not allow a lower level to be struck should

a fall occur. Do not allow product to contact sharp

or abrasive surfaces, sparks or temperatures

above 180 degrees.

• Snap hooks with gate openings larger than

one inch (1”) must not be connected.

•

Remove from service if any damage is detected

This product is part of a personal

fall arrest system; a fall arrest

system is required if there is any

risk that a worker may fall from an

elevated position. It is a

requirement that the fall arrest

system be used any time a working

height of six feet or more is

reached. Working height is defined

as the distance from the

walking/working surface to a grade

or lower level.

1.

2.

3.

4.

5.

6.

7.

1. Back 'D' ring is for fall arrest

2. Shoulder 'D' rings. (if present) are for retrieval use

only use locking snaps.

3. Side 'D' rings (if present) are for positioning only.

4. Front 'D' ring (if present) is for fall arrest

(foot first falls only, 2 foot max free fall), work

positioning, travel restraint or rescue

5. Hip attachment elements are for work positioning

or travel restraint

6. Visual load indicator

7. Park lanyard here

NOTE:See additional instructions on buckle adjustment for proper fit. aximum free-fall distance six feet or

energy

absorber arresting force of 900 lbs per ANSI or maximum fall arrest force of 1800 lbs per OSHA.

Avoid lower level contact.