viii

10.6. Signals.................................................................................................................................................32

10.6.1. Output voltage.................................................................................................................................................32

10.6.2. HV ON signal: Pin 5......................................................................................................................................33

10.6.3. Discharge check signal: Pin 4.......................................................................................................................33

10.6.4. Setpoint: Pins 3, 7, 11.....................................................................................................................................33

10.6.5. RS485 communication: Pins 10, 12............................................................................................................33

11. PIRANI GAUGE BPR2/SP1 ....................................................................................34

11.1. Sensor Unit Setting: “SP1”............................................................................................................. 34

11.2. Front Panel.........................................................................................................................................34

11.2.1. Pressure display...............................................................................................................................................34

11.2.2. Description of front panel keys....................................................................................................................34

11.3. Setting Operation..............................................................................................................................34

11.3.1. RS-485 communication operation setting “L1”, “L2”............................................................................34

11.3.2. Operation setting method..............................................................................................................................35

11.4. Connecting to The Sensor Unit...................................................................................................... 35

11.5. Connection with External Devices................................................................................................36

11.6. External Input/Output Signal.......................................................................................................... 36

11.6.1. Output voltage.................................................................................................................................................36

Burnout signal...............................................................................................................................................................37

11.6.3. Setpoint.............................................................................................................................................................37

11.6.4. RS-485 communication.................................................................................................................................37

12. HOT CATHODE GAUGE BMR2............................................................................38

12.1. Sensor Unit Setting: “Sn1” .............................................................................................................38

12.2. Front Panel.........................................................................................................................................38

12.2.1. Pressure display...............................................................................................................................................38

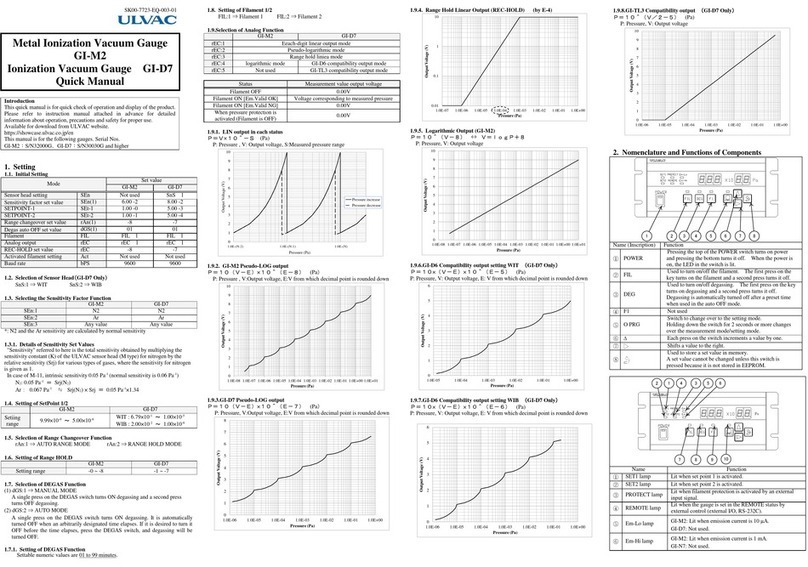

12.2.2. Description of front panel keys....................................................................................................................38

12.3. Setting Operation..............................................................................................................................38

12.3.1. Setting overview .............................................................................................................................................38

12.3.2. RS-485 communication operation setting “L1”, “L2”............................................................................39

12.3.3. Front panel, external I/O operation setting.................................................................................................39

12.3.3.1. Filament operation setting “F1”.............................................................................................................39

12.3.3.2. Degas operation setting “dE”.................................................................................................................39

12.3.3.3. Filament changeover setting “FL” ........................................................................................................39

12.3.3.4. Operation setting method........................................................................................................................40

12.4. Connection with The Sensor Unit .................................................................................................41

12.5. Connection with External Devices................................................................................................ 41

12.6. Various Signals .................................................................................................................................42

12.6.1. Output voltage.................................................................................................................................................42

12.6.2. Filament on signal...........................................................................................................................................42

12.6.3. Degas on signal ...............................................................................................................................................42