www.ungerglobal.com www.ungerglobal.com2 3

HydroPower® RO

Table of Contents

1 Introduction................................................................................................................ 4

1.1 General information............................................................................................. 4

1.2 Product lifetime guarantee.................................................................................. 4

2 Safety Information...................................................................................................... 4

2.1 Safety alert symbols and signal words................................................................ 5

2.2 Warning signs ...................................................................................................... 6

2.3 Mandatory signs................................................................................................... 7

2.4 General safety information.................................................................................. 8

2.4.1 Basic principles........................................................................................... 8

2.4.2 Unit protection............................................................................................. 8

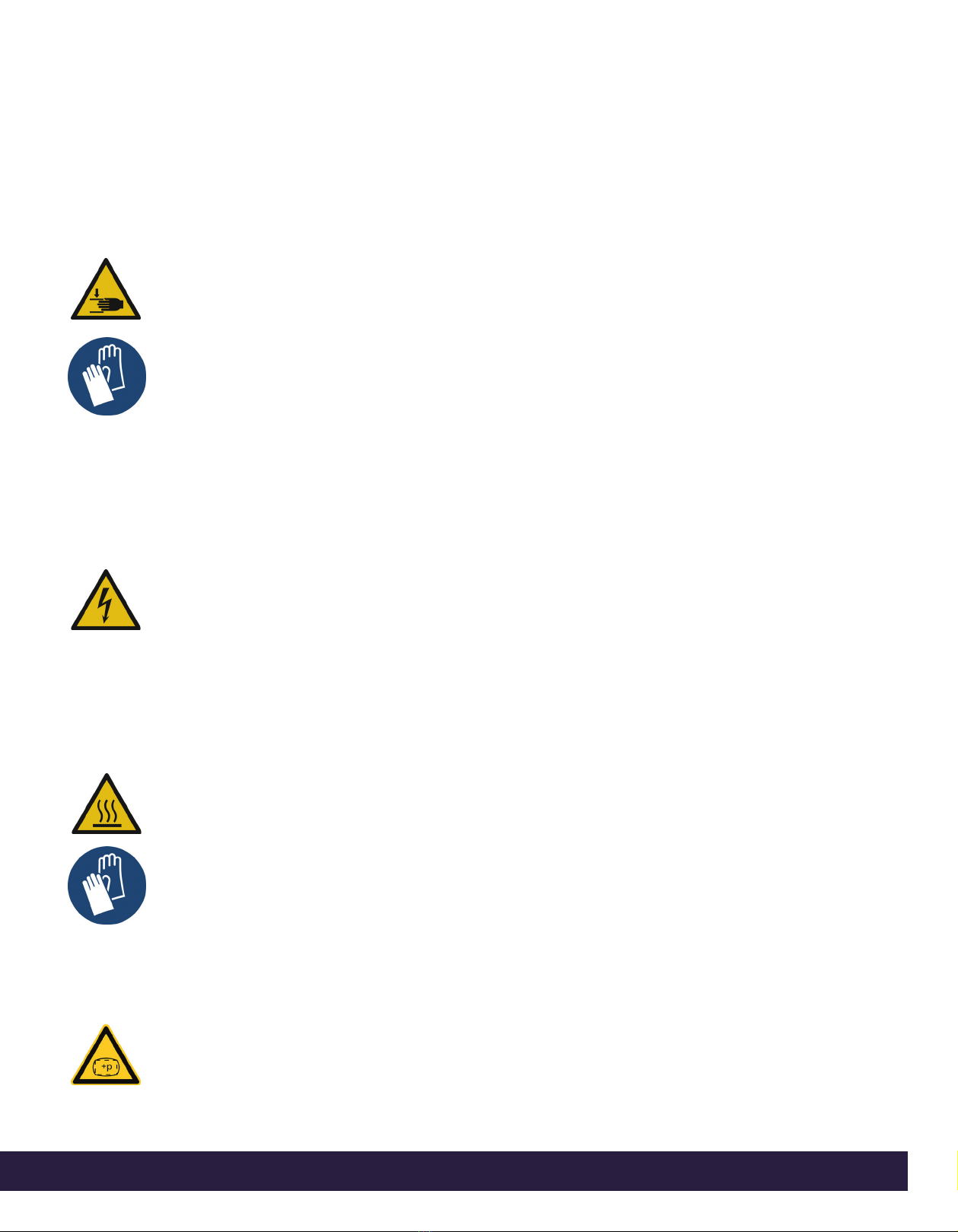

2.5 Mechanical hazards ............................................................................................. 9

2.6 Electrical hazards ................................................................................................ 9

2.7 Thermal hazards.................................................................................................. 9

2.8 Hazards due to pressure...................................................................................... 9

2.9 Hazards from materials and substances ............................................................ 10

2.10 General hazards................................................................................................... 11

2.10.1 Technical label ............................................................................................ 11

2.11 Responsibilities of the operator .......................................................................... 12

2.12 Storing the operating instructions ...................................................................... 13

2.13 Contact address ................................................................................................... 13

3 About HydroPower RO ............................................................................................... 14

3.1 Using the HydroPower RO .................................................................................. 14

3.1.1 Intended use................................................................................................ 14

3.2 Technical specifications....................................................................................... 14

3.2.1 Operating conditions ................................................................................... 14

3.2.2 Electrical specifications .............................................................................. 14

3.2.3 Protection types of electrical components ................................................. 14

3.2.4 Pressure ratings.......................................................................................... 15

3.2.5 Dimensions quick overview ........................................................................ 15

3.2.6 Media connections ...................................................................................... 15

3.2.7 Water quality ............................................................................................... 15

3.3 Water output quantity .......................................................................................... 15

3.4 System products and accessories ....................................................................... 15