www.ungerglobal.com www.ungerglobal.com

Unger‘s pre-measured replacement Ultra Resin Packs are designed to allow

a controlled resin expansion within a designed safety limit.

1. SHUT OFF FEED WATER SUPPLY

• Depress yellow lever on system head assembly.

• Turn tap water valve to “OFF” position.

• Disconnect waterfed wash pole hose.

2. RELEASE SYSTEM HEAD ASSEMBLY

• While continuing to depress the yellow lever, use a counter-clockwise

quarter‐turn to release system head assembly; remove and set aside.

• Reach into housing and remove exhausted resin by hand; discard

according to local regulations.

• Press yellow FastLock opening lever (g. E) to remove pressure from

the tank.

• Steady (or “Stabilize”) the base unit with your feet, gently press the top

cap down and use a counter-clockwise 1/8 turn to release top cap

assembly; remove and set aside (g. F).

• Open all valves to facilitate the removal of the Ultra Resin Packs.

• Reach into housing and remove exhausted Ultra Resin Pack(s) by hand

with the rubber handle (g. G); discard according to local regulation

System Overview

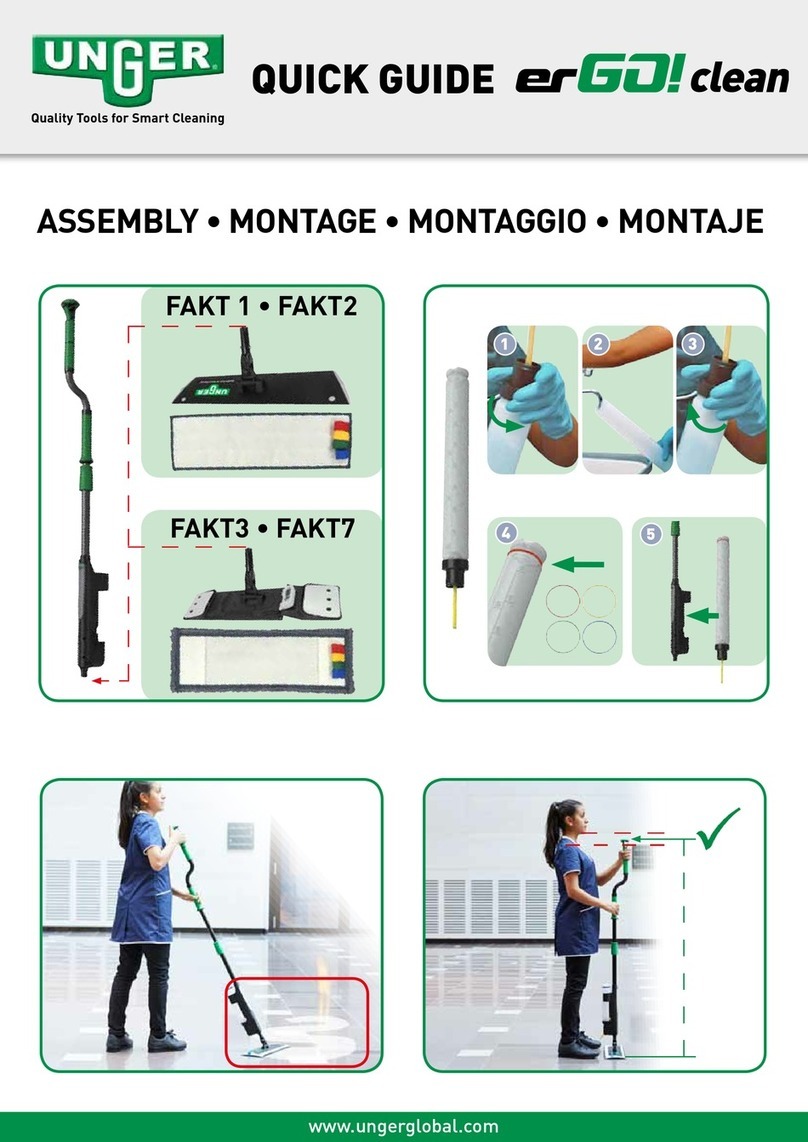

System Setup

D

H

A

E

I

B

F

J

C

G

K

L

Resin Change

23

21064

Water OUT Connection with

O-Ring

21063

O-Rings (5), Care Resolution

21071

Top Cap Assembly

21151

TDS Meter

21504

Water IN Hose Connection

21066

FloWater™Unit

21065

Water IN On/Off Connection

4. TURN ON FEED WATER SUPPLY

• When water begins to ow out of the unit, turn on TDS meter and

inspect pure water quality (g. D). A reading of ‘0’ is best and indicates

the system is running properly. When the TDS meter reaches 10ppm or

higher the resin should be replaced.

• Adjust ow at waterfed pole brush head by:

- Tap water valve or,

- Waterfed wash pole control (on/o) valve (if applicable).

1. LOCATE JOBSITE WATER SUPPLY

Unger recommends testing the on‐site water supply for TDS (total dissolved solids)

prior to working. Higher TDS levels reduce the system’s capacity.

• Inspect system – ensure Unger‘s Ultra Resin Packs are properly installed: the

red Resin Pack is only used on a 3-stage unit and placed in the middle and

bottom position. The green Resin Pack is used in all units and is placed in the top

position. NOTE: The performance of HydroPower Ultra is optimized when used

with Ultra Resin Packs. NEVER use loose resin as it may damage the system.

• Set up system in upright position.

• Choose a stable on‐site location.

2. CONNECT WATERFED WASH POLE TUBING

• Attach waterfed wash pole hose onto Water OUT connection (g. A).

• Ensure all on/o valves are in “OPEN” position when lling system.

3. CONNECT WATER SUPPLY (GARDEN HOSE) TO WATER IN CONNECTION

• Thread On/O Valve to garden hose prior to connecting water supply (g. B).

• Attach On/O Valve directly onto Water IN connection at base of unit (g. C).

3. REPLACE ULTRA RESIN PACKS

• Install new Ultra Resin Packs (g. H) – be sure to seat the packs with

rubber handle facing up. Pat down the pack by hand to ensure it is

seated properly.

Small tank unit (UHP01):

= 1x green Ultra Resin Pack

(never use red Ultra Resin Pack

in this unit!)

Large tank unit (UHP3C):

=

1x green Ultra Resin Pack (top position)

2x red Ultra Resin Packs (middle + bottom position)

green

red

red

green

4. REINSTALL TOP CAP ASSEMBLY

• Press down gently, then turn the top cap 1/8 clockwise while

steadying the base unit with your feet.

5. RECONNECT WATERFED POLE TUBING (g. I)

• Turn “ONˮ water supply at tap (g. J).

• Inspect system as it pressurizes.

• Keep discharge line open and hold down yellow lever to remove

trapped air from system (g. K).

6. TEST SYSTEM TDS (g. L) The value should be at 000.