VELUX®5

Product

• The control system has been designed for use with genuine VELUX prod-

ucts. Connection to other products may cause damage or malfunction.

• The control system is in conformity with the Low Voltage Directive and

the EMC Directive for use in household, trade, industry and light industry.

• When installed, the control system complies with protection degree

IP 42.

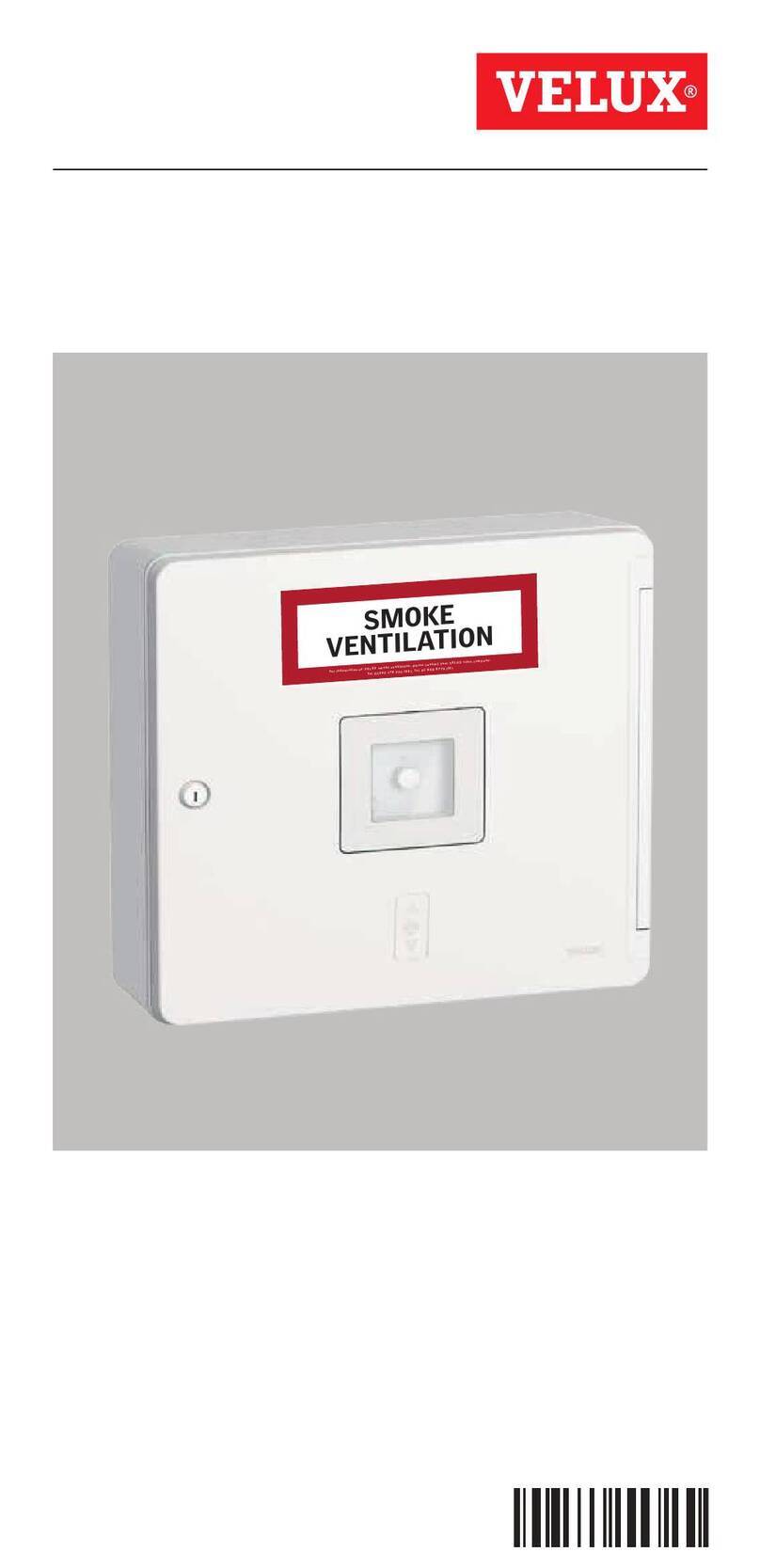

• The control system can operate smoke ventilation windows with a total

power consumption of 10 A (KFC 210) and 2 x 10 A (KFC 220) respec-

tively.

• The packaging must be disposed of in accordance with national regula-

tions.

• Products, including batteries if any, marked with the crossed out

wheeled bin are regarded as electrical and electronic equipment and

contain hazardous materials, components and substances. The crossed

out wheeled bin symbolises that electrical and electronic equipment

waste must not be disposed of together with household waste. It must

be collected separately at recycling stations or other collection sites or

retrieved directly from households to increase the possibilities of recyc-

ling, reuse and utilisation of electrical and electronic equipment waste.

By sorting electrical and electronic equipment waste with this symbol,

you contribute to reducing the volume of incinerated or buried waste and

to reducing any negative impact on human health and the environment.

Further information can be obtained from the local municipality's techni-

cal administration or from your VELUX sales company.

• If batteries can be removed, product and batteries must be disposed of

separately.

Installation

• Installation must be carried out by a certified person in accordance with

current national regulations.

• The control system must be connected directly to the mains supply in ac-

cordance with national regulations. Ensure that the mains supply cannot

be disconnected unintentionally. It is recommended that disconnection

is only possible using the mains switch or a key switch. At least one of

these means for disconnection must be incorporated in the fixed wiring in

accordance with national wiring requirements.

Maintenance and service

• Disconnect mains supply and back-up batteries before carrying out any

maintenance or service work to the control system and ensure that they

cannot be reconnected unintentionally during this time.

• The control system must be tested after installation, service work and

alterations to the system. It must be inspected by qualified personnel at

least once a year. Tests and inspections must be documented in accord-

ance with national regulations.

• At the yearly inspection, the connected products must be checked ac-

cording to their instructions.

• The printed circuit board monitors the time between inspection periods.

If more than 15 months have passed since the last inspection, the yellow

light-emitting diode is on and an acoustic alarm sounds.

• The batteries must be checked at the yearly inspection. We recommend

that the batteries are replaced at least every four years.

• If you have any technical questions, please contact your VELUX sales

company, see telephone list or www.velux.com.

Important information