Please proceed as follows:

Replacing Fluorescent Lamp:

(a) Turn off power to the unit. .

(b) Grip the bulb at both ends, near the connectors and twist

the bulb approximately 90 degrees.

(c) Gently pull the bulb out of the connectors.

(d) Reverse this process to fit, ensuring that the bulb is held

firmly and correctly within the connectors before releasing.

UNDER SHELF LIGHTING (Optional extra)

The shelf lights are individually controlled via switches on the

lamp fittings. They can be accessed from the customer side. The

switch is near the left hand side. (The shelf lights can be

accessed through rear doors on enclosed models) To change a

lamp, proceed as replacing lamps above, except the lamp end

covers need to be slid across and removed after (a). When

replacing the lamp end covers, they just clip back into place.

4. CLEANING

Switch off the unit at the mains before cleaning.

The tray in the base can be removed to access the underneath

area enabling spillages and crumbs to be cleaned up. Take care

not to touch the heat exchanger as it may have sharp edges.

Shelves and brackets can be removed for cleaning. Ensure that

they are replaced securely afterwards.

For enclosed units, cleaning access can be gained by tilting the

front glass out to the open rest position. For greater access the

glass screen can be lifted right out. The glass is heavy or very

heavy and will need 2 people to lift it.

Where fitted, the perforated clear plastic panel(s) in the rear

door(s) can be removed for cleaning. Slide the perforated clear

plastic panel up out of the door. Replace before use.

Stainless steel surfaces will give you many years of trouble-free

use as long as you follow a few simple rules. If it appears to

mark do not worry, it is usually not the steel but something

deposited on it which has stained.

Wash all surfaces before use:

You should use a damp cloth and a mild detergent or soap, or

similar cleaner. Always rinse well with clean water and dry the

surface with a soft cloth. Clean regularly when in use. Do use

soft cloths, nylon or bristle brushes.

Do not use:

Metal scrapers, wire brushes or wire wool pads as they can

scratch the steel. Do take care when handling sharp objects as

they can scratch the surface of stainless steel. Any scratches on

stainless steel will blend together over a period of time and

become less noticeable with age. There is no detriment to the

corrosion resistance or general performance of the material.

Do not use:

Bleach for cleaning purposes (remember dishwasher powders,

sterilising agents and similar products all contain chlorides). If

used, black pit marks, large brown patches or other such effects

may appear and permanent damage may be caused. If used

inadvertently rinse immediately with clean water.

the food temperature. Other buttons on the controller are of no

consequence to the user and are for factory or service engineer

use only.

To obtain the best performance, the following procedure is

suggested:

(a) Switch on the refrigeration system via the switch located on

the control panel.

(b) Depending on the ambient temperature, allow the display

approximately 30 minutes to reach the required temperature.

(c) Load the display. Do not load the shelves too densely. Please

leave gaps between adjacent items to enable adequate

airflows. Please also leave a gap between the top of the food

items and the shelf above.

All refrigeration systems frost up when operating. Your

appliance has a microprocessor control, programmed to defrost

periodically. No manual defrost is required. The refrigeration

system will automatically defrost every 2 hours for

approximately 20 minutes.

The controller will display‘def’ during the defrost cycle, then rec

as the systems recovers temperature. Water collected from the

defrost operation is automatically evaporated.

Please remember: The refrigeration system is not designed to

chill food, but is designed to maintain it at a satisfactory

temperature before serving.

REAR DOORS (enclosed models)

The lower door hinges up, and the upper door hinges down.

The two doors can’t be open at the same time. When the top

door is lowered it can be used as a shelf to assist loading the

cabinet.

REAR DOORS (open fronted models)

Changing the hinging from left to right

The door(s) hinges outward to facilitate loading and cleaning.

Whilst the unit is running, only open them for the minimum

time possible. On 1000 and 1300 sizes there are 2 doors but on

the 650 there is 1. As standard, the 650 is supplied opening to

the left from the operator’s side. However it is simple to alter

the hinging to be from the other side.

Unscrew and remove the cover plate from the non hinge side.

Slide the perforated clear plastic panel up out of the door. Hold

onto the door and unscrew the hinges from the cabinet. Rotate

the door through 180o so that the hinges go to the side that

you want them fixed to. Fasten the hinges to the cabinet. Slide

the perforated clear plastic panel into the door from the top.

Re-fix the cover panel.

SHELVES; REMOVAL AND HEIGHT ADJUSTMENT

(a) The glass shelves may be removed for cleaning. On enclosed

models the glass may be removed through the rear doors.

(b) With the glass out, the shelf height can be adjusted up or

down 15mm.

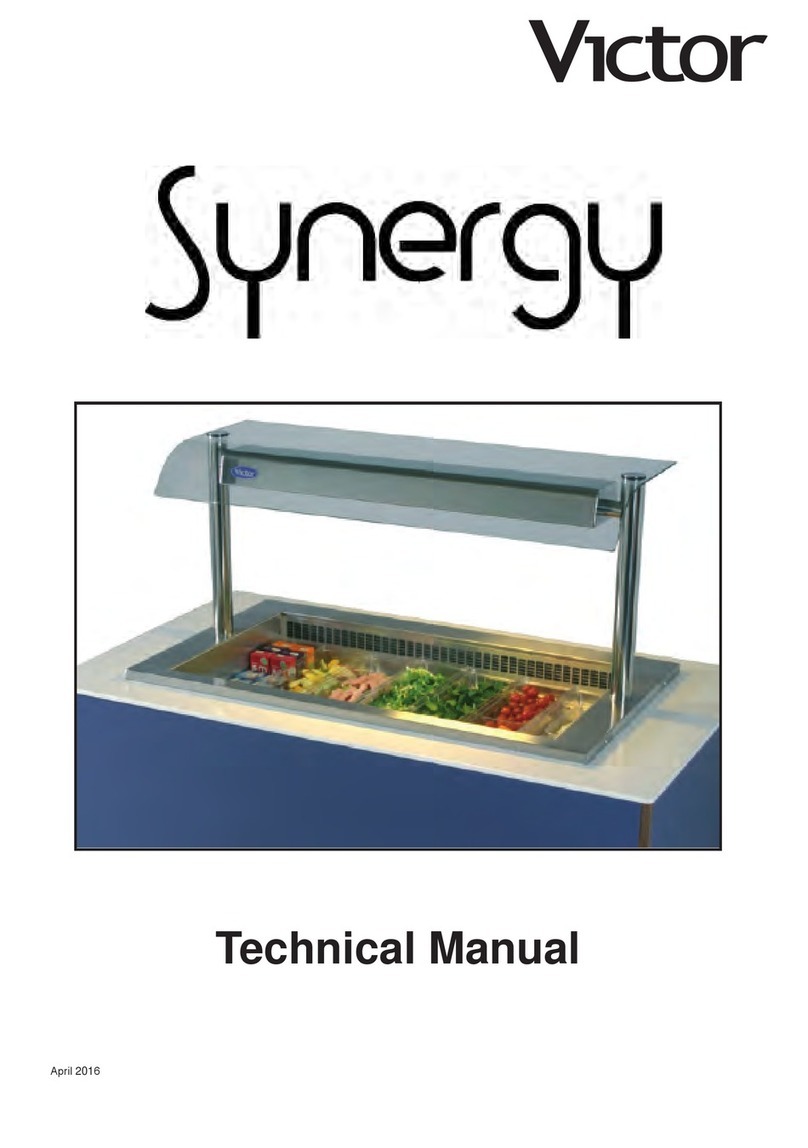

CANOPY

The canopy is fitted with a fluorescent tube controlled by an

on/off switch on the rear of the unit (inside cabinet on wall

style models) adjacent to the refrigeration control. The lamp is

replaceable.