English

Installation and operating instructions Wilo-SC/SCe-HVAC 45

1 General ................................................................................................................................................. 46

2 Safety ................................................................................................................................................... 46

2.1 Symbols and signal words in the operating instructions ................................................................................ 46

2.2 Personnel qualifications ..................................................................................................................................... 47

2.3 Danger in the event of non-observance of the safety instructions .............................................................. 47

2.4 Safety consciousness on the job ....................................................................................................................... 47

2.5 Safety instructions for the operator ................................................................................................................. 47

2.6 Safety instructions for installation and maintenance work ........................................................................... 48

2.7 Unauthorised modification and manufacture of spare parts ......................................................................... 48

2.8 Improper use ........................................................................................................................................................ 48

3 Transport and interim storage ........................................................................................................... 48

4 Intended use ........................................................................................................................................ 48

5 Product information ........................................................................................................................... 49

5.1 Type key ............................................................................................................................................................... 49

5.2 Technical data ...................................................................................................................................................... 49

5.3 Scope of delivery ................................................................................................................................................. 49

5.4 Accessories .......................................................................................................................................................... 49

6 Description and function .................................................................................................................... 50

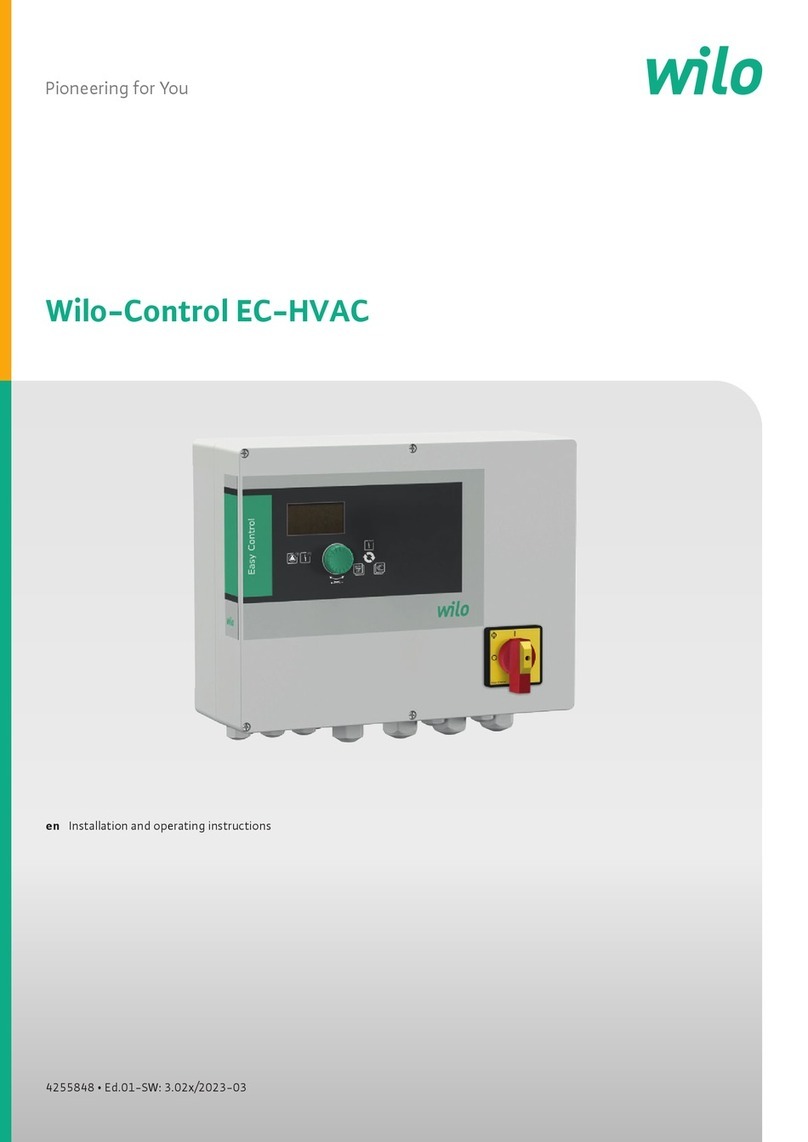

6.1 Description of the product ................................................................................................................................. 50

6.1.1 Function description ........................................................................................................................................... 50

6.1.2 Set-up of the control device .............................................................................................................................. 50

6.2 Function and operation ....................................................................................................................................... 51

6.2.1 Operating modes of the switchgear .................................................................................................................. 51

6.2.2 Control modes ..................................................................................................................................................... 54

6.2.3 Motor protection ................................................................................................................................................. 55

6.2.4 Operation of the switchgear .............................................................................................................................. 56

6.2.5 Menu structure .................................................................................................................................................... 62

6.2.6 Operation levels .................................................................................................................................................. 78

7 Installation and electrical connection .............................................................................................. 78

7.1 Installation ........................................................................................................................................................... 78

7.2 Electrical connection .......................................................................................................................................... 79

7.2.1 Mains connection ................................................................................................................................................ 79

8 Commissioning .................................................................................................................................... 84

8.1 Factory setting .................................................................................................................................................... 84

8.2 Checking the motor direction of rotation ........................................................................................................ 84

8.3 Adjusting the motor protection ......................................................................................................................... 85

8.4 Signal transmitters and optional modules ........................................................................................................ 85

9 Maintenance ........................................................................................................................................ 85

10 Faults, causes and remedies .............................................................................................................. 85

10.1 Fault display and acknowledgement ................................................................................................................. 85

10.2 History memory for the faults ........................................................................................................................... 86

11 Spare parts ........................................................................................................................................... 87

12 Disposal ................................................................................................................................................ 87