2

Contents

1General information..............................4

1.1 Initial start-up................................................. 4

1.2 Information about this operating manual ....... 4

1.3 Notes............................................................. 4

1.4 Intended use ................................................. 4

1.5 Components.................................................. 5

1.6 Transportation............................................... 5

1.7 Disposal ........................................................ 5

1.8 Manufacturer................................................. 6

2Important information ..........................6

3Specification..........................................7

3.1 Measured values........................................... 7

3.2 Calculated values.......................................... 9

3.3 Logger function ........................................... 10

3.4 Technical data............................................. 11

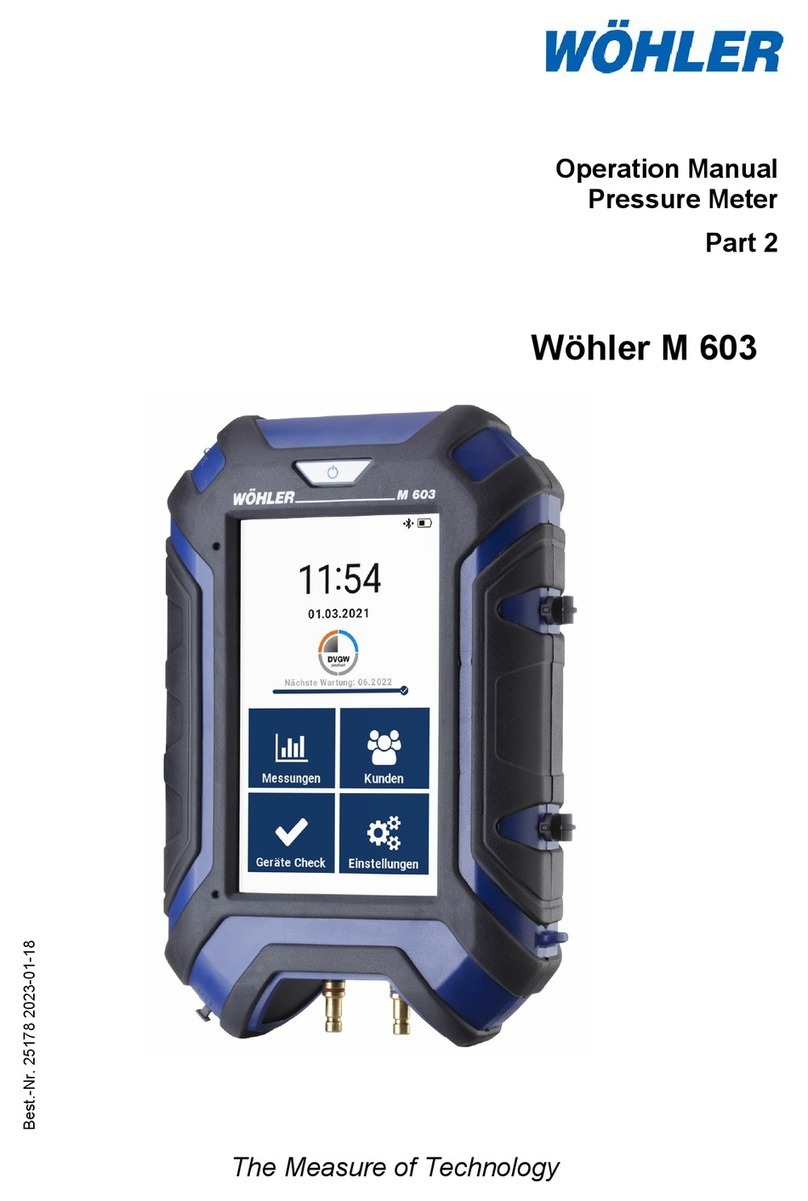

4Layout and functions .........................12

4.1 Basic device ................................................ 12

4.2 Connector panel.......................................... 12

4.3 Protective covers......................................... 14

4.4 Sensors and connection components ......... 14

4.5 Touch display .............................................. 17

5Prior to use ..........................................19

5.1 Charging the battery.................................... 19

5.2 Leak tightness test ...................................... 20

6Starting the unit ..................................20

7Connecting the Wöhler M 603 to one or

more Wöhler SC 660 units..................21

7.1 Connection via the settings menu ............... 22

7.2 Connection during live measurement.......... 23

7.3 Connection prior to pressure testing with water

.................................................................... 24

8Measurements on gas pipes..............25

8.1 Stress test on gas pipes .............................. 26