2

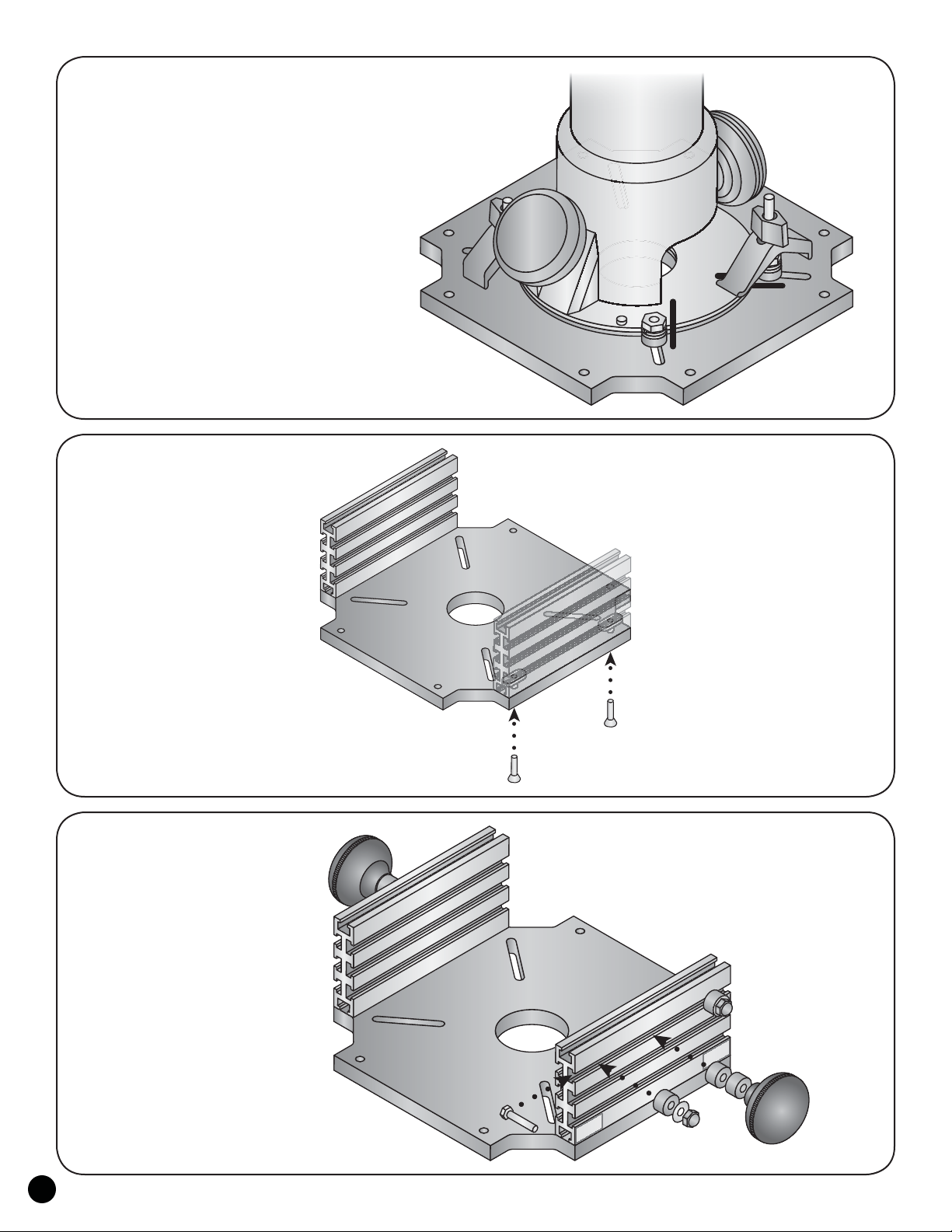

ASSEMBLY - BRACKETS & RAILS

Install a washer (WS002) on eight of the 1" bolts

(HB030). From the ribbed side of the Sled Bracket, insert

the bolts through the holes in the Sled Brackets

(3000B - 4 brackets - 2 pairs) and start an oval

nut (5760B), flat side first, on the end of each

bolt. Sliding the oval nuts into the T-slot of the

Double Track, mount a pair of Sled Brackets to both

Double Tracks (4016, 4024 or 4032, depending on model

purchased).

Position the pair of brackets so they are 3-5/8"

apart (measured from the inside ends - this gap will

be adjusted later), flush with the edge of the Double

Track and centered on it, then tighten the bolts. Insert

a 1" bolt (HB030) through the hole in the rib on each

Sled Bracket and install two washers (WS002) and ratchet

handle (5860) on the end of each bolt.

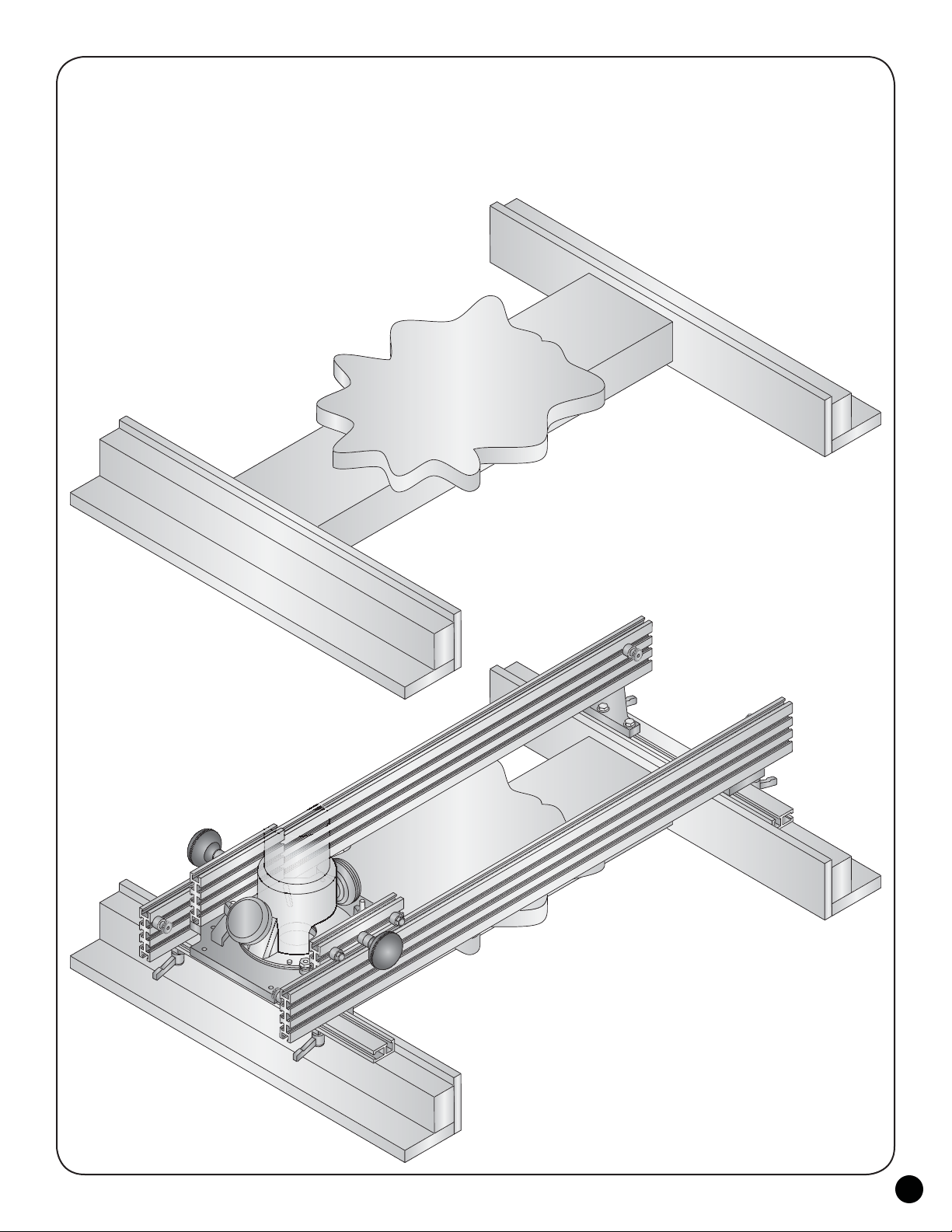

Set the Ultra Tracks on a flat surface, making sure

they are on the same plane. Install the Sled Brackets/

Double Track on the Ultra Tracks (4436, 4448 or 4460

depending on model purchased) by sliding the bolt

head/rib of the bracket into the T-slot of each Ultra

Track.

For now, position the Sled Brackets so they are

2" from the ends of the Ultra Tracks and tighten the

ratchet handles.

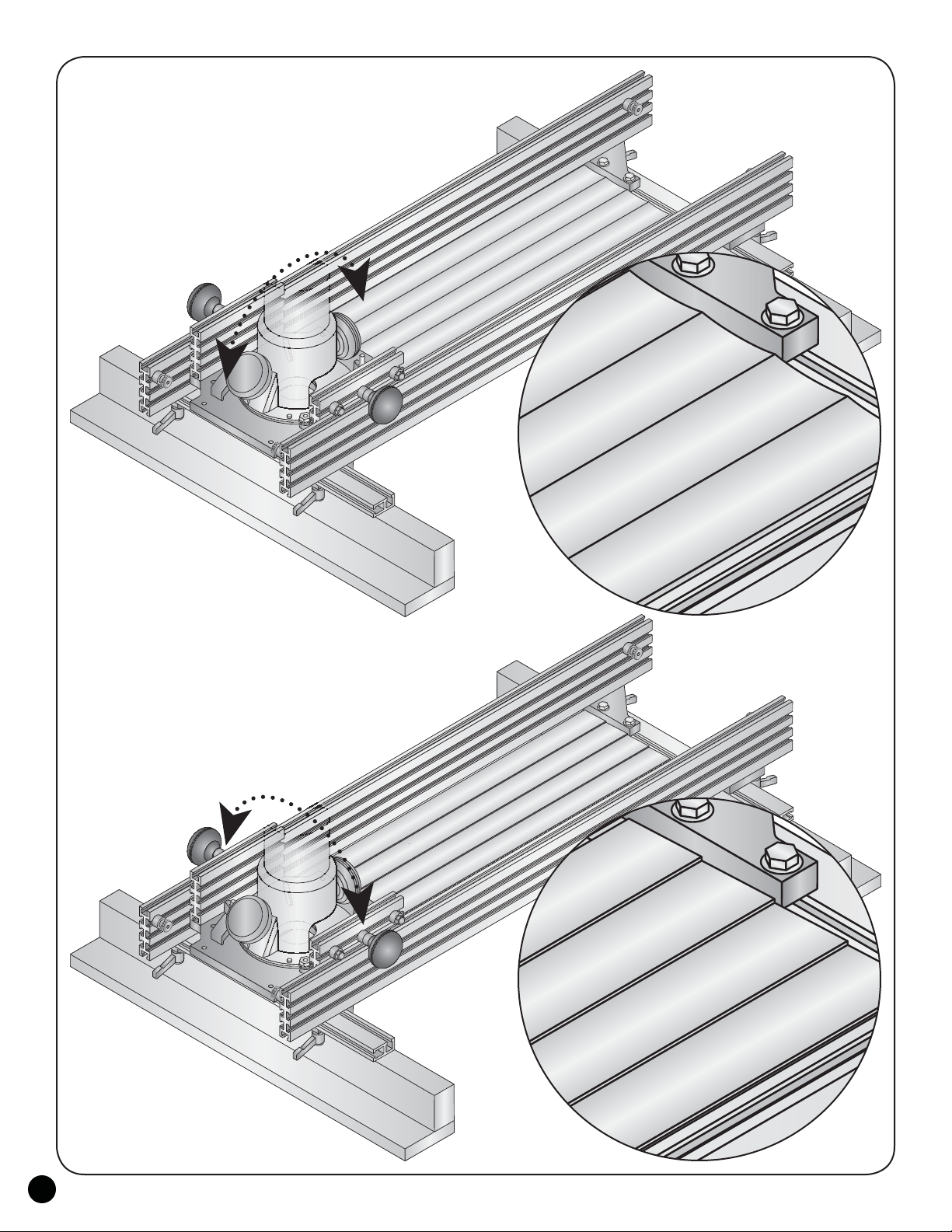

Take the Router Sled (router should not be

installed yet) and place it as shown on the top of the

two Ultra Track rails. Loosen the knobs and four acorn

nuts, dropping the Router Sled slightly downward

between the Ultra Tracks, then tighten the acorn nuts.

This adjustment should allow the four spacers/glides of

the Router Sled to sit evenly on the Ultra Track rails.

Flip the Router Sled over between the Ultra Tracks and tighten

the two knobs on the Router Sled so those spacers are not touching the

Ultra Track rail. Double check that the Router Sled does not rock on

the Ultra Track rails.

Loosen one of the Ultra Track rails by loosing the Sled

Brackets where they attach to the Double Tracks. Adjust the

Ultra Track rail against the Router Sled so it moves freely,

but with very little side-to-side slop between the Ultra

Track rails, then retighten the Sled Brackets.

Install a spacer (BUSH050), washer (WS002)

and knob (5521) on a 3/4" bolt (HB020) and insert

the head of each bolt in the upper side T-slot of one of the

Ultra Tracks. These act as stops to control the front-to-back

movement of the Router Sled on the Ultra Track rails.

HB030 x1 per bracket

WS002 x2 per bracket

5860 x1 per bracket

3-5/8"

Sled Brackets 2"

in from the ends

of the Ultra

Tracks

HB030 x2 per bracket

WS002 x2 per bracket

5760B x2 per bracket