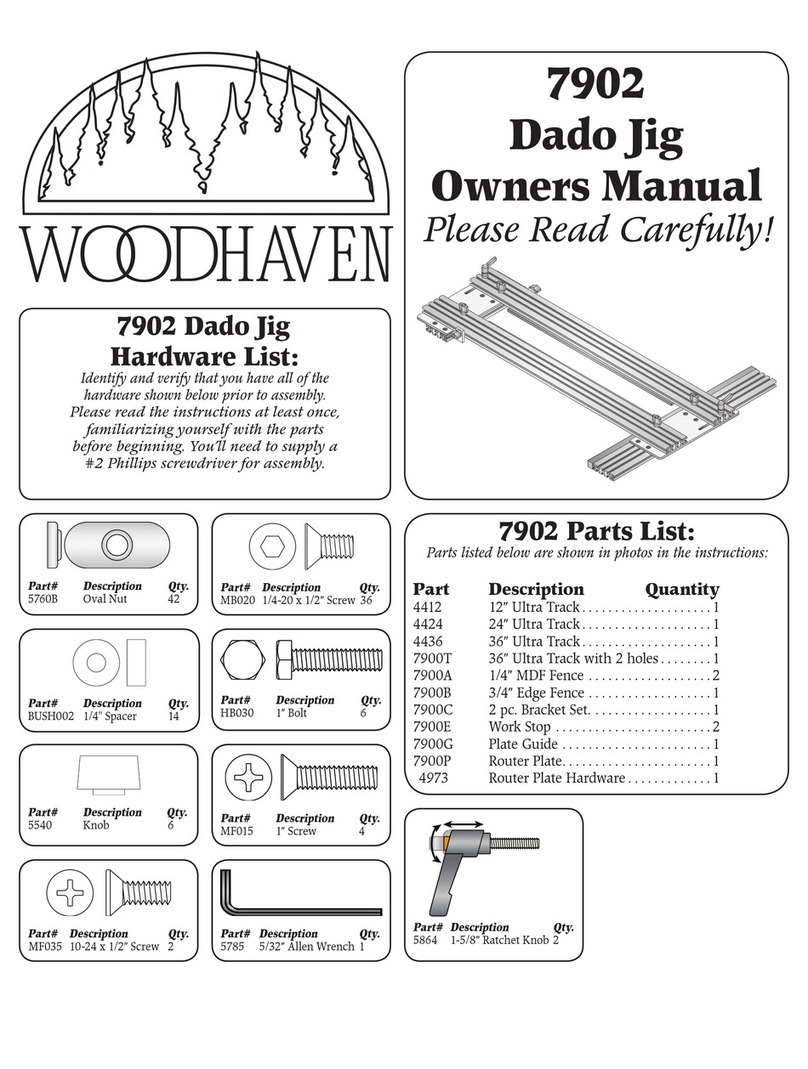

1

Holes/bolts in Tracks

face each other

Installa5/8"screw(MF006)thruthecountersunk

holesineachofthe5-7/8"OneTracks(5432S)and

startanovalnut(5765B - smooth side first)onthe

endofeachscrew.Therearetwoholesineachof

the6-3/4"UltraTrackFences(5432T).One

holeis3/4"fromtheendoftheFence

andtheotherholeis1-1/2"from

theoppositeendoftheFence.

Placethelongedgesofthetwo

Fencesagainsteachothersotheholesareclosest

toandacrossfromeachothertoinsureyouhave

mirrorimagesofthetwoFencesafterassembly.

AttheendofeachFence,wheretheholeis1-1/2"

fromtheend,installaOneTrack.Insertthetwooval

nutsontheOneTrackintheT-slotsoftheFence,butt

thelongedgeoftheOneTrackagainsttheendofthe

Fence,checkitforsquareandtightenthescrews.

Installawasher(WS002)oneachof

the1-1/4"bolts(HB040).Placethe6-3/4"

UltraTrackFence(5432T)ontheBase

(5432B)withtwoholesineachFence

alignedwiththetwoslotsintheBaseand

theOneTracksbuttedagainsttherearedge

oftheBase.ThetwoholesintheFences

shouldfacetowardsthecenteroftheBase.

Insertthe1-1/4"boltsthrutheholes

intheFence/slotsinBaseand,fromthe

undersideoftheBase,startanoval

nut(5760B - smooth side first),

ontheendeachbolt.Position

theFencesabout12"apartfor

nowandsnugthebolts.

Inserttwo3/8"screws(MP375)thru

thetwofrontholesofeachToggleClamp

(6305)andstartanovalnut(5765B -

raised side first)ontheendofeachscrew.

SlideoneToggleClampontoeachFence,

withtheovalnutsengagedinthecenter

T-slot.PositiontheToggleClampswhere

desiredandtightenthescrews.Forquicker

spindleadjustments,replacethetopnuton

thespindlewiththethumbnut(5525).

Inserta5/8"spacer(BUSH004 on

thetwo1"bolts(HB030)andstartaknob

(5590)ontheendofeachbolt.Slidethe

boltheadintoaT-slotofthefence,

positioningtheknobwheredesired

forbestcontrol,andtighten.

5765B x2

MF006 x2

HB040 x2

WS002 x2

5760B x2

5590 x1

5525 x1

BUSH004 x1

MP375 x2

5765B x2

HB030

x1

5432S &

5432T

5432B