3

10

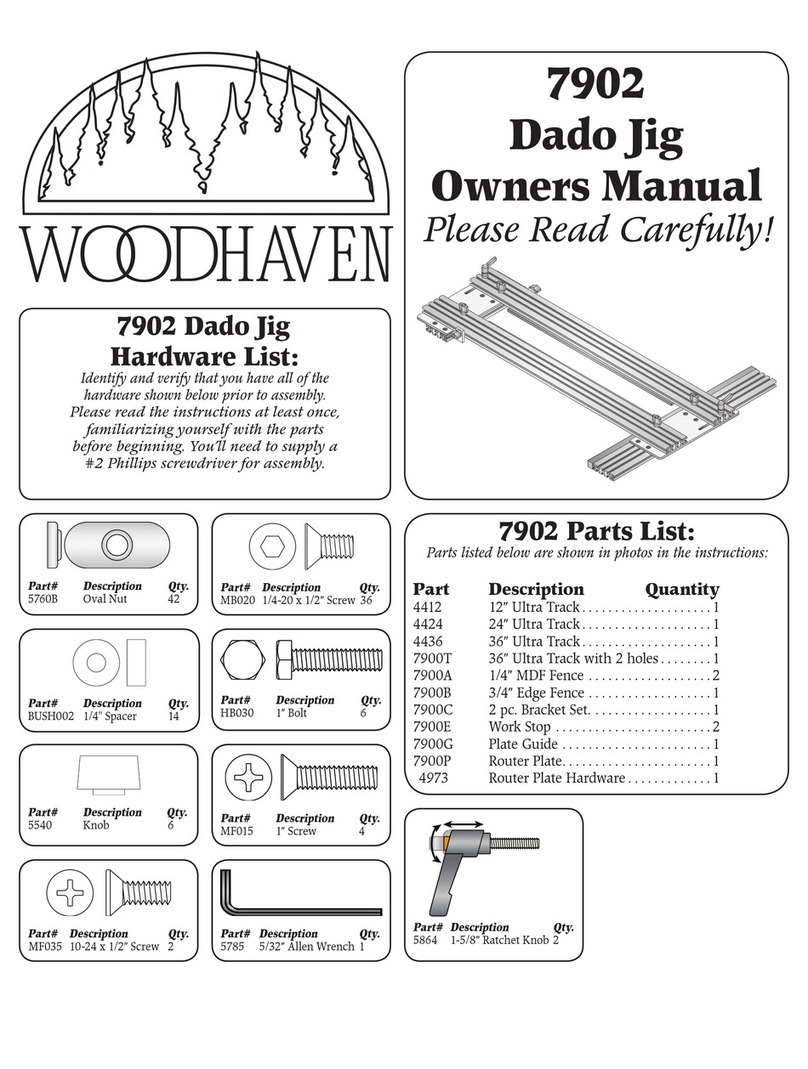

Place the arm plate (1475A2) with it’s groove covering

the threaded rod and fasten it to the adjuster arm using

the 3/4" screws (5771B). Align the top and bottom edge

of both parts before tightening the screws. See fig. 9.

Adjust the two nuts on the threaded rod, along with

the washers, against the underside of the adjuster arm.

Tighten the nuts against each other when you have adjusted

the up/down slop out of the height adjuster. See fig. 9.

ROUTER INSTALLATION

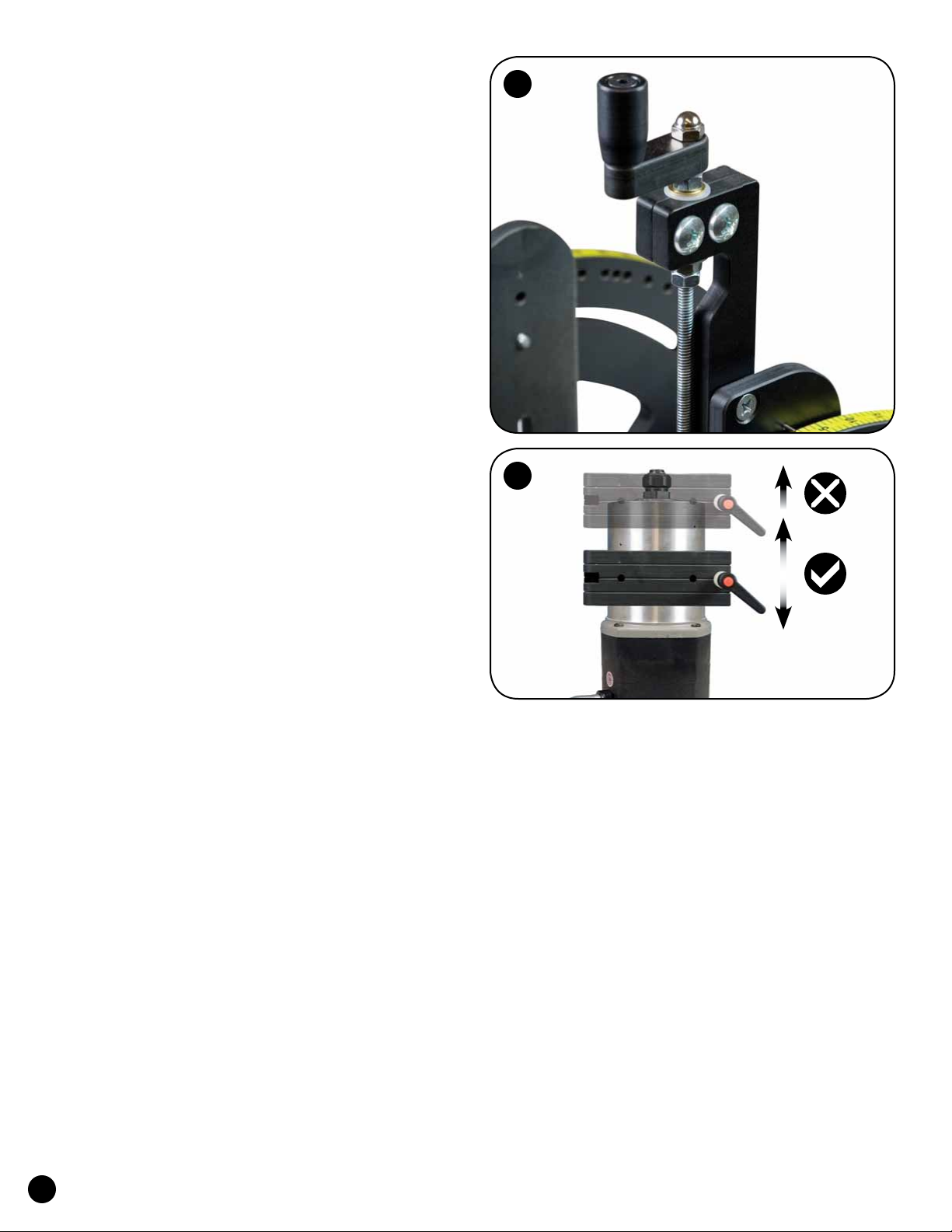

Loosen the clamp handle in the router block and insert

your router in the router block so the end of the motor is flush

with the router block, or protruding out past it.. The router

motor should always be fully inserted in the router block!

Never insert a router motor partially in the router block! The

router motor can be repositioned anywhere in the motor block as

long as it is completely in the motor block at all times. Tighten

the clamp handle just enough to hold the router motor. Do not

over-tighten or you may damage your router. See fig. 10.

ANGLE SETTINGS

There are pin settings at 0, 5, 10, 15, 20, 22-1/2, 25, 30,

35, 40 & 45 degrees, or you can set your desired angle using the

scale on top of the sides as a guide. To set an angle, remove the

two pins (if used), loosen the two angle adjustment knobs and

pivot the router to the desired angle. Replace the pins (if the

angle is one of the pin settings above) and tighten the knobs.

Angle settings other than those provided can

be set using a drafting square or bevel gauge placed

between the plate and the face of the router block.

HEIGHT ADJUSTMENT

IMPORTANT!! Loosen the height knob nearest the

Height Adjuster just 1/4 to 1/2 of a turn and loosen the

opposite height knob 2 full turns. Retighten the knob nearest

the Height Adjuster first, then retighten opposite knob.

Turn the crank handle on the Height Adjuster to

move the router up or down. If you cannot achieve the

desired height, you may have to reposition the router in

the router block (see router installation section above).

USING THE ANGLE EASE

There are two ratchet knobs for locking the height and

two for locking the angle. Perform one of these adjustments

at a time instead of attempting both adjustments at the same

time. Make sure your bit is locked securely in the router

collet and that all knobs are tightened securely before using.

Depending on your table opening size, you may have to

set the Angle-Ease at 0º degrees to insert it in your router table.

To reduce the risk of injury we recommend that

you tilt the cutter into the fence (or table) hiding more

of the cutter compared to tilting the cutter away from

the fence (or table) and exposing more of the cutter.

©Copyright WOODHAVEN INC. 9/18/07

(800)344-6657 or WWW.WOODHAVEN.COM

9