2

BEFORE BEGINNING

Identify and verify that you have all the parts listed.

Read the instructions at least once before beginning. This jig

is designed for marking/mounting 35mm or 26mm cup hinge

mounting plates (with 32mm on center mounting holes) at a

distance of 37mm to 70mm from the edge of the cabinet.

ASSEMBLY

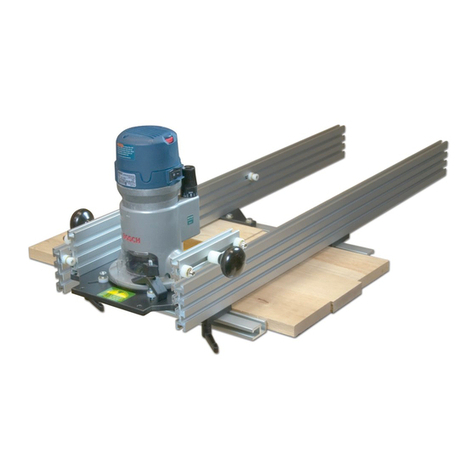

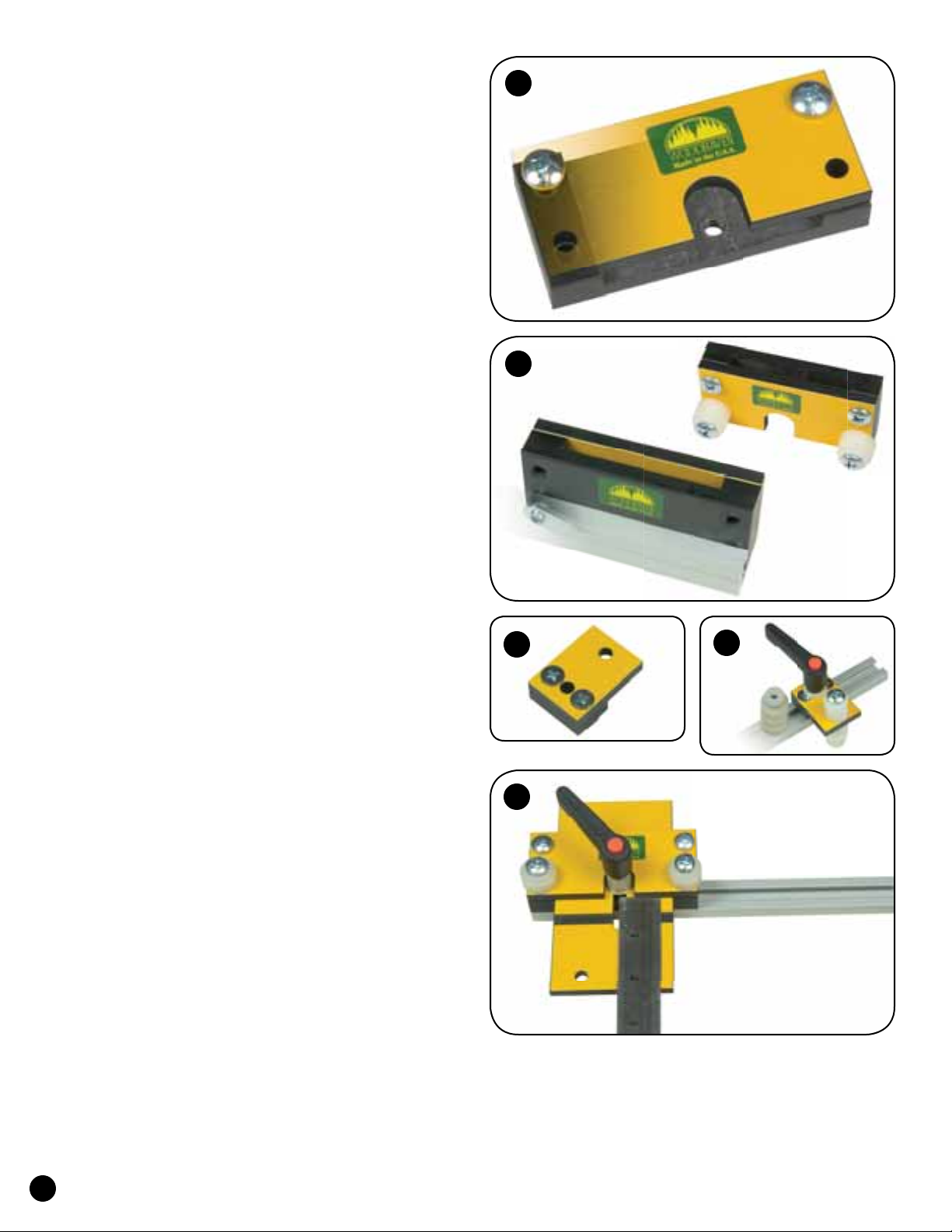

Attach the 1/4" Cap (8610C) to the 1/2" Cap

(8610A) using the 3/4" screws (5771B). See fig. 1.

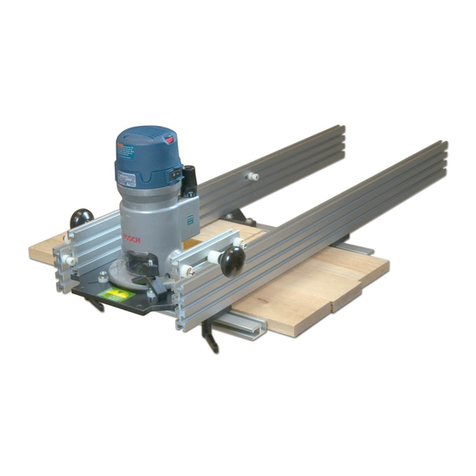

Install a 1/8" Spacer (BUSH001) and a 3/8" Spacer

(BUSH050) on both of the 1-1/2" Screws (MP150). Insert the

screws thru the two open holes in the Caps and start an Offset

Oval Nut (5765B) on the end of each screw. See fig. 2.

Lay the assembly on edge. Slide the 7-7/8" One Track

(4208) on to the offset oval nuts until it's flush with one end

of the assembly, then tighten the 1-1/2" screws. See fig. 2.

Insert three 3/8" Spacers (BUSH050) on the 1-1/2"

Bolt (HB050) and start a Thumb Nut (5521) on the end of

the bolt. This assembly provides support for the jig when it's

flipped and is best positioned next to the Indexing Plate. Slide

the assembly on the One Track and tighten. See fig. 4.

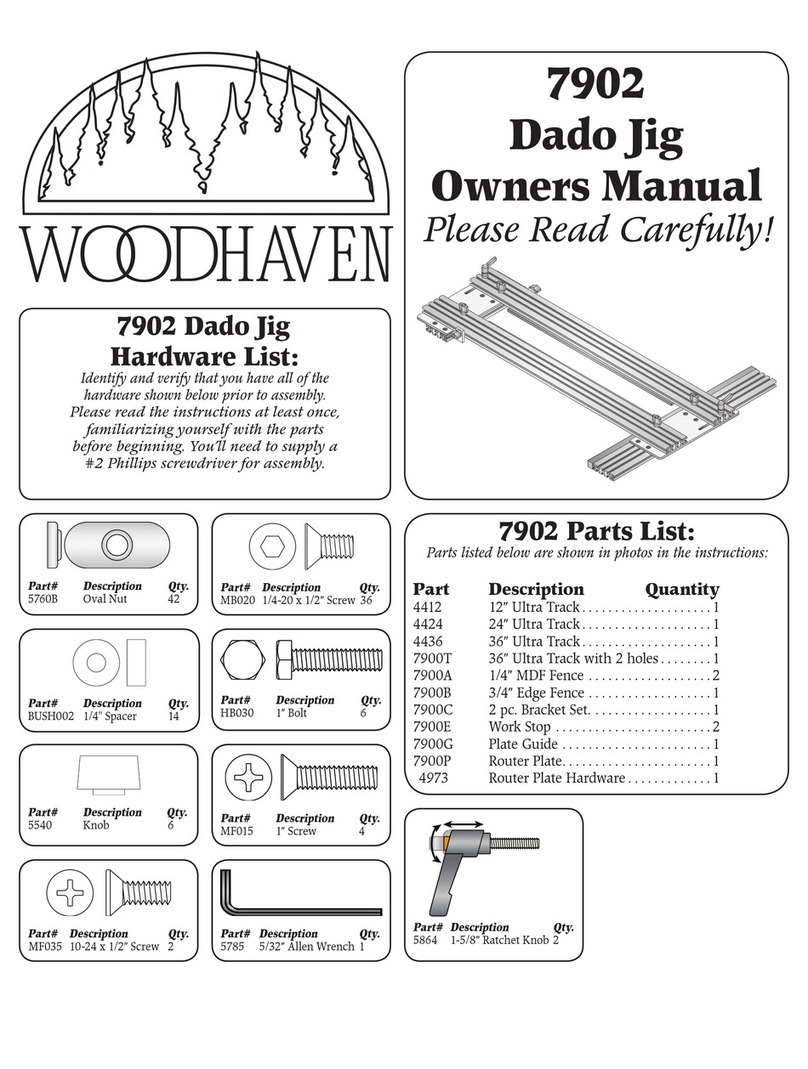

Attach the Indexing Plate (8610D) to the Indexing Plate

Riser (8610E) using the 1/2" screws (MF035). See fig. 3.

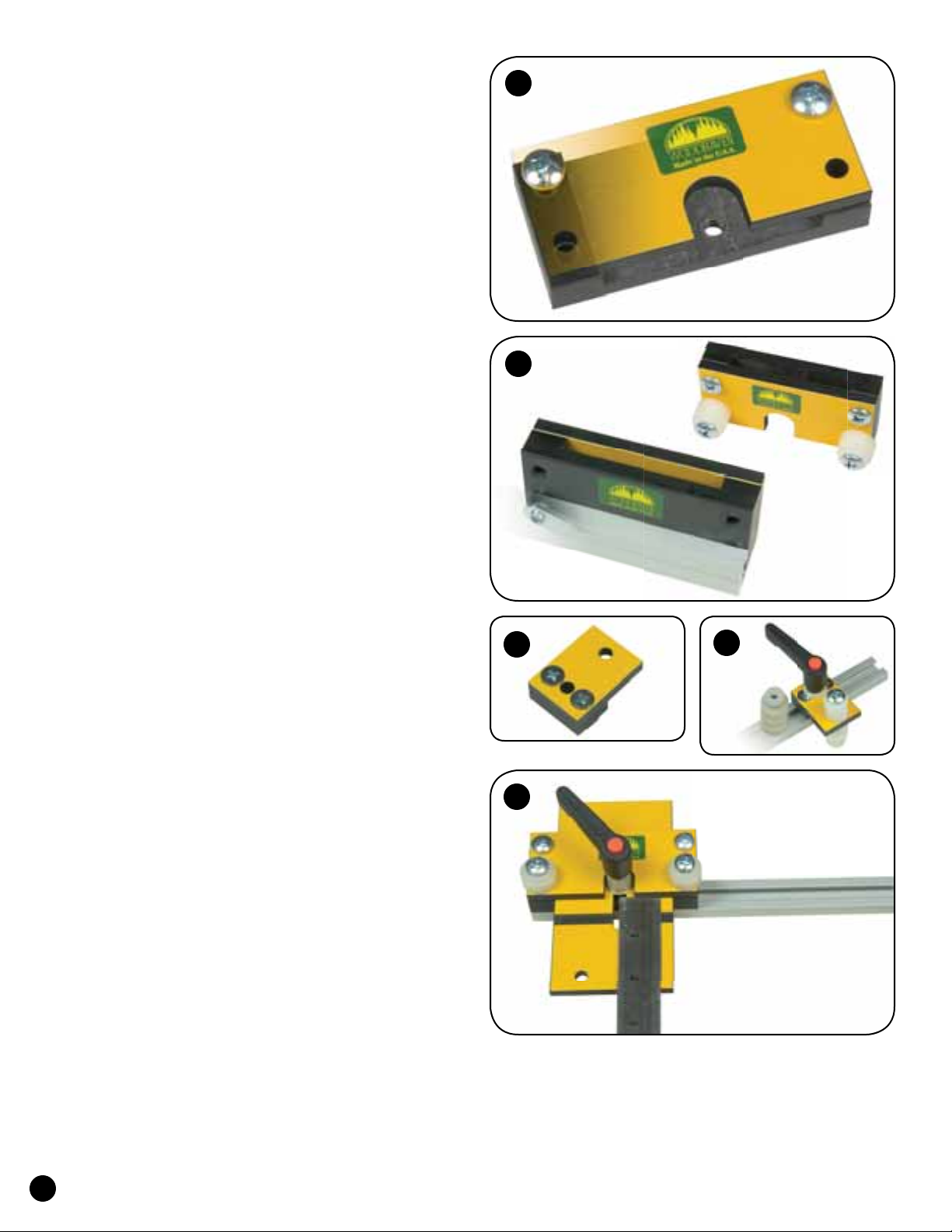

Insert a 1" bolt (HB030) thru the Riser, then the

Indexing Plate. Install a 1/8" Spacer (BUSH001) and start

a Ratchet Handle (5860) on the end of the bolt. Slide the

assembly on the One Track and tighten. See fig. 4.

If you're indexing the jig off the edge of a door or panel,

install a 5/8" Bushing (BUSH004) on the 2" Screw (MP200),

insert the screw thru the hole in the Indexing Plate, install

another 5/8" Bushing and then the Thumb Nut (5521). If

you're indexing the jig against the inside of a cabinet, don't

install this hardware on the Indexing Plate. See fig. 4.

Slide the Base (8625B) in the slot of the assembly with

the shallow black groove in the base facing the 1/4" Cap. The

slot in the Base should be lined up with the tapped hole in

the 1/2" Cap below it. Install a 1/2" Bushing (BUSH5050)

and a washer (WB002) on a Ratchet Handle w/stud (5863).

Install the Ratchet Handle w/stud thru the slot in the Base

and start it in the tapped hole in the 1/2" Cap. See fig. 5.

USING THE JIG

By aligning the edge of the shallow black groove in the

Base with the edge of the 1/4" Cap, the marking holes will

be 37mm from the edge of the jig. This 37mm dimension is

the built-in offset. By moving the Base/marking holes further

from the 1/4" Cap, you'll increase the distance of the plate

from the edge of the cabinet. Be sure to add the measurement

between the Cap and the groove to 37mm to get the actual

distance. For example, if the distance measures 23mm, plus

the 37mm built-in offset, the actual distance to the center

line of the marking holes will be 60mm. See fig. 5.

Flip the jig to go from left to right or top to bottom.

Use a 1/4" Marking Punch (8600) to mark the

holes for drilling. Or use a Self-Centering bit (6507

or 6507) to drill the screw pilot holes and mark

the 35mm or 26mm cup hole for drilling.

©Copyright WOODHAVEN INC. 9/18/06

(800) 344-6657 or WWW.WOODHAVEN.COM

5

2

1

34

One Track