© Zennio Avance y Tecnología S.L. Edition 2 Further information www.zennio.com Page 2/2

SAFETYINSTRUCTIONSANDADDITIONAL NOTES

•Installation should only be performed by qualified professionals according to the laws and regulations applicable in each country.

•Do not connect the mains voltage nor any other external voltage to any point of the KNX bus; it would represent a risk for the entire

KNX system. The facility must have enough insulation between the mains (or auxiliary) voltage and the KNX bus or the wires of other

accessories, in case of being installed.

•Once the device is installed (in the panel or box), it must not be accessible from outside.

•Keep the device away from water (condensation over the device included) and do not cover it with clothes, paper or any other material

while in use.

•The WEEE logo means that this device contains electronic parts and it must be properly disposed of by following the instructions at

https://www.zennio.com/en/legal/weee-regulation.

•This device contains software subject to specific licences. For details, please refer to https://zennio.com/licenses.

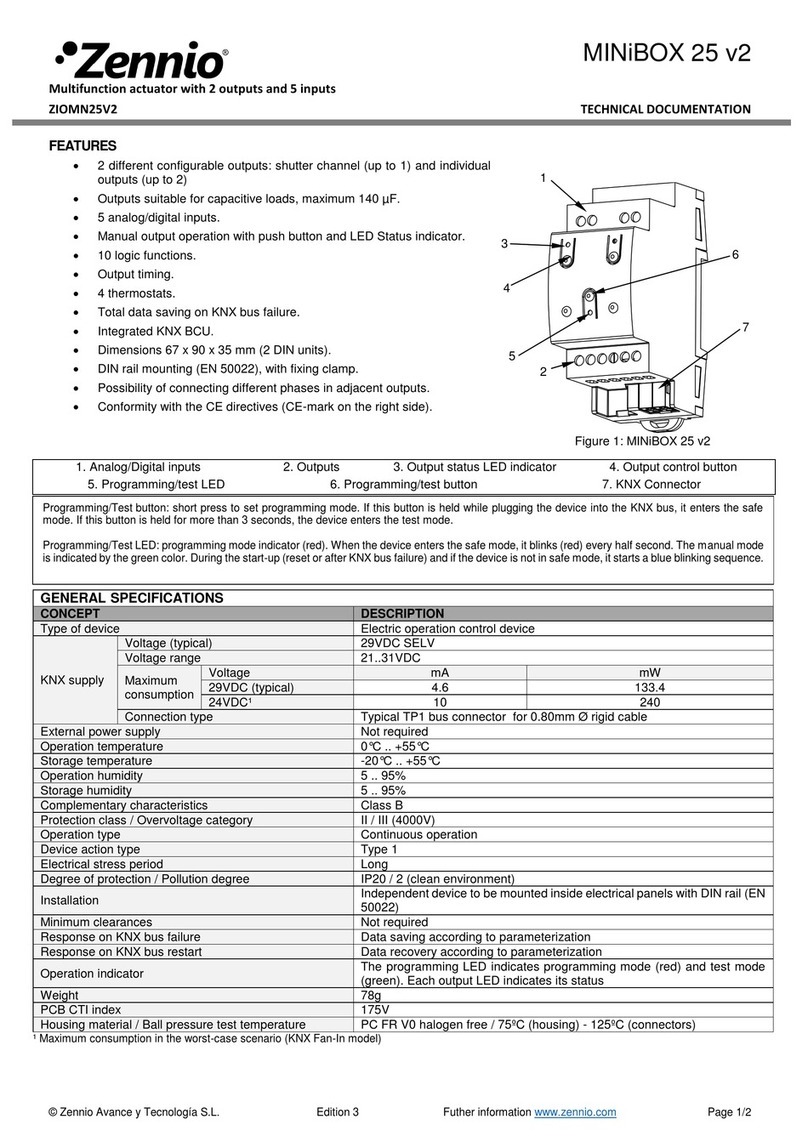

OUTPUTS SPECIFICATIONS AND CONNECTIONS

Output type / Disconnection type

Potential-freeoutputsthrough bistablerelays with

tungsten pre-contact / Micro-disconnection

AC 16(6) A @ 250 VAC (4000 VA)

DC 7 A @ 30 VDC (210 W)

Connections in adjacent outputs

Possibility of connecting different phases. It is not

allowed to connect power supplies of different

order, SELV with NO SELV, in the same block.

Total maximum current in device

Screw terminal block (0.5 Nm max.)

0.5-4 mm² (IEC) / 20-12 AWG (UL)

Mechanical lifetime (min. cycles)

Electrical lifetime (min. cycles)1

100000 @ 8 A / 25000 @ 16 A (VAC)

¹ Lifetime values could change depending on the load type.

INPUTS SPECIFICATIONS AND CONNECTIONS

1 mA @ 3.3 VDC (per input)

Dry voltage contacts between input and common

Screw terminal block (0.4 Nm max.)

0.5-2.5 mm² (IEC) / 26-12 AWG (UL)

1.5 m (extensible up to 30 m)

² For Zennio temperature probes.

⚠In order to ensure the expected status of the

relays, please check that the device is connected to

the KNX bus before energizing the power circuit.

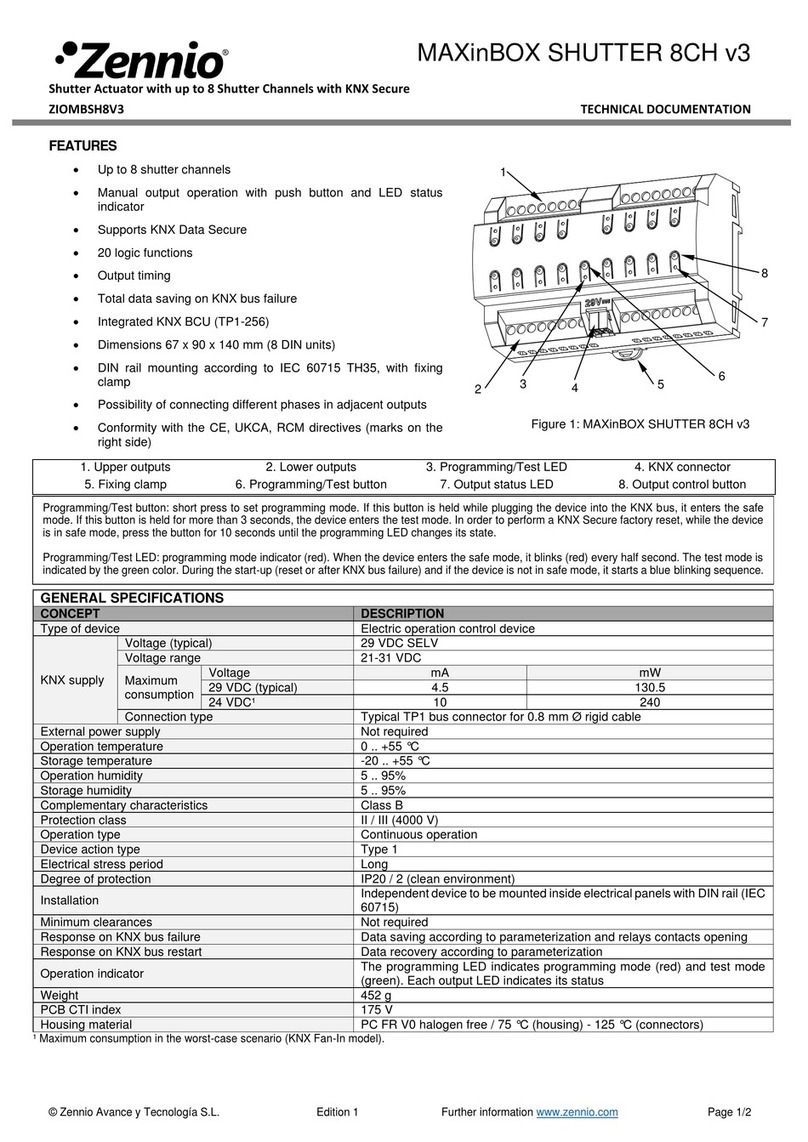

Figure 2: Wiring example (from left to right,

and up to down): 2 loads, 2 loads connected

to different phases, shutter and fan coil

* In case of using ZN1IO-DETEC-P sensor, its micro switch number 2 must be in Type B position.

** Zennio temperature probe or any NTC with known resistance values at three points in the range [-55, 150 ºC].

Any combination of the following accessories is allowed in the inputs:

Zennio temperature

probe.

can be plugged into the

same device input (parallel

connecting Zennio motion

sensors*

Switch/Sensor/

Push button

A1 A2

M

N

L

A1 A2

N

L

L1 L2

A1 A2

NL1

L1 L2

L2

CIN CIN

C I

CIN

Attaching MINiBOX 45 v3 to DIN rail:

Removing MINiBOX 45 v3 from DIN rail:

A1 A2

M

N

L

A1 A2

N

L

L1 L2

A1 A2

NL1

L1 L2

L2

CIN CIN

C I

CIN

Commons of different devices

must not be connected together.