10

Setup

3. Adjust the air supply regulator (F) to about 100 psi.

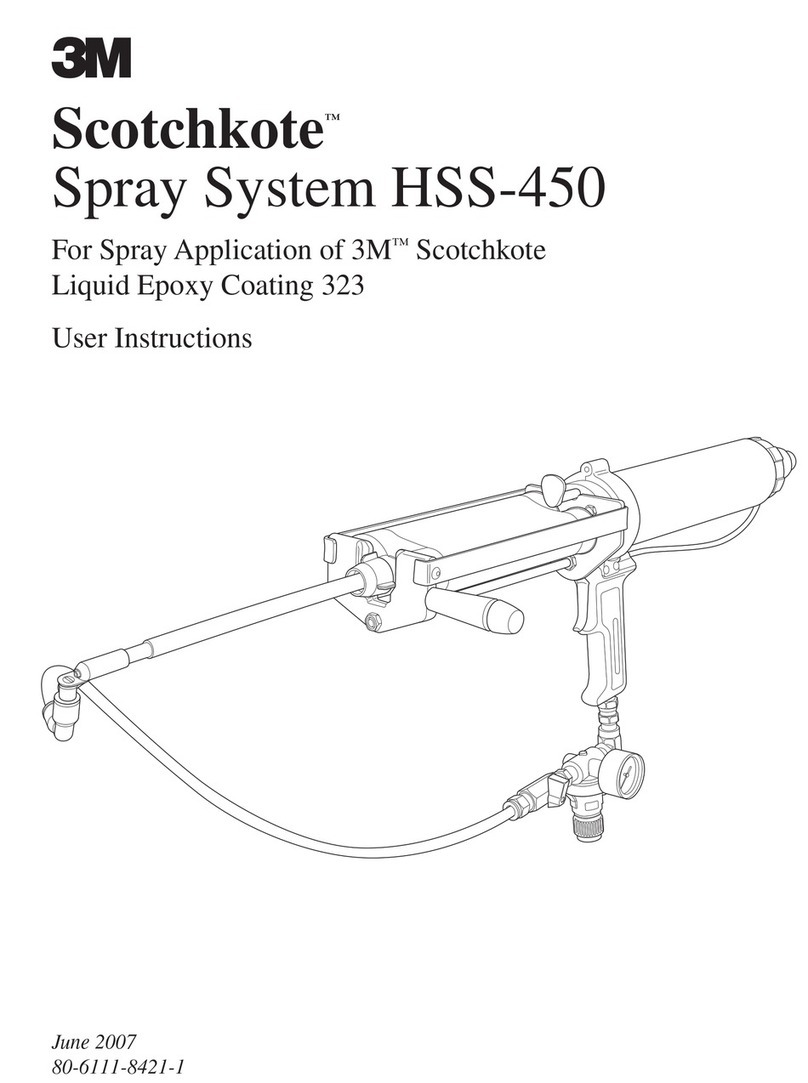

Fig. 12

F

01997

4. Trigger the gun and adjust the gun inlet pressure,

turning the needle valve at the gun air inlet:

HVLP, Compliant 29 psi

Airspray 50psi

5. Spray a test pattern to evaluate fluid flow and

atomization.

6. To reach the desired pattern width, fluid flow rate,

and finish, make the following adjustments:

. For a narrower pattern (25), turn the pattern

adjustment valve clockwise.

. To reduce the fluid flow, turn the fluid adjust-

ment valve (21) clockwise to limit the trigger

travel or replace the nozzle with a smaller

orifice.

. To improve atomization, reduce the fluid flow

rate. Increasing the air pressure can improve

atomization but may result in poor Transfer

Efficiency (TE) or non–compliant operation.

WARNING

PRESSURIZED EQUIPMENT HAZARD

To avoid injury, never open the fluid adjustment

knob (21) beyond the one half turn indicated in

Adjusting the Spray Pattern, page 9. If the red

band on the knob stem (21) is visible, the knob is

not adjusted correctly and could result in serious

injury. Repeat steps in Adjusting the Spray

Pattern, page 9.

7. For HVLP only, to measure the air cap atomizing

pressures, use the accessory aircap verification

kit.

NOTES:

If the fluid adjustment knob is turned in clockwise

all the way the gun will emit only air.

For maximum transfer efficiency, always use the

lowest air setting needed to achieve the desired

finish.

If available, use the fluid manufacturer’s recom-

mendations for this gun model to set the air line

pressure.

For Compliant guns, to maintain compliant opera-

tion (TE equal to HVLP) the gun inlet pressure must

not exceed 29 psi.

For HVLP guns, at 29 psi (200 kPa, 2.0 bar) gun

inlet air pressure, the pressure at the aircap will be

10 psi (70 kPa, 0.7 bar).

For HVLP guns, local laws may limit the maximum

automatic air pressure to 10 psi (70 kPa, 0.7 bar) at

the air cap for HVLP compliance. The accessory Air

Cap Verification Kit 16231 is available to measure

the atomizing pressure at the air cap.