6

SAFETY INFORMATION

Please read, understand, and follow all safety information contained in these instructions prior to

the use of this Spray Gun Kit. Retain these instructions for future reference.

Intended Use:

This Spray Gun Kit is intended to provide the means to apply liquid coatings via a spraying process�

This Spray Gun Kit is used in automotive, industrial, and finishing applications� It is expected that all

users be fully trained in the safe operation of this Spray Gun Kit� Use in any other application has not

been evaluated by 3M and may lead to an unsafe condition�

Explanation of Signal Word Consequences

WARNING: Indicates a hazardous situation which, if not avoided, could result in serious

injury or death

CAUTION: Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury and/or property damage�

NOTICE: Indicates a hazardous situation which, if not avoided, could result in property

damage only�

WARNING

•To reduce the risks associated with chemical exposure, hazardous pressure, fire/explosion, or

environmental contamination:

• Read, understand and follow all safety statements in applicable equipment user’s manuals to

avoid possible safety hazards�

• Ensure you are familiar with the controls, functionality, and proper use of the equipment�

• Use only in a well ventilated area�

• Never perform unapproved modifications or maintenance on this product�

• Always comply with local, state, and national laws and regulations governing ventilation, fire

protection, operation, maintenance, and housekeeping� Consult applicable SDS(s) and material

container labels for each material being sprayed in the work area�

•To reduce the risks associated with fire and explosion:

- Ensure VOC concentration is kept below ignition threshold per liquid coating material SDS(s)�

- All ignition sources such as smoking or electrical devices must be kept out of the spray area�

- Always maintain a readily available, approved fire extinguisher or other approved fire fighting

equipment in or near the spray area�

- When operating this unit, use only undamaged suitably solvent-resistant and appropriately

pressure-rated static-conductive air hoses�

- Users are expected to comply with local regulations for working in explosive environments

and any requirements for the material to be sprayed (consult material SDS) and use

appropriate PPE for both� [Note: This may include grounding with shoes, heel straps, and

static conductive (or static dissipative) gloves�]

•To reduce the risks associated with chemical exposure, hazardous pressure and impact:

• Do not maintain or service the spray gun other than as instructed in the user’s manual�

• If fasteners were removed for hardware maintenance or accessories, ensure that all fasteners are

replaced and tightened before operation�

•To reduce the risks associated with chemical exposure and hazardous pressure:

- Do not use this product around unsupervised children�

- Never point a spray gun at anyone else or place any part of your body in front of the spray gun�

- Before use check spray equipment for damage and proper function� Repair/replace worn,

damaged or malfunctioning components with 3M approved components�

- Ensure the equipment you are using with this product is suitable for the use application�

•To reduce the risks associated with bursting and chemical exposure:

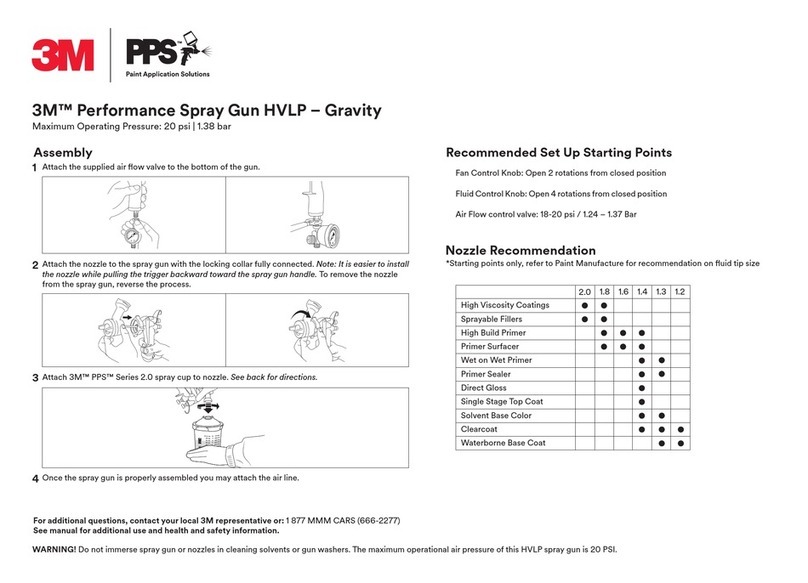

- Do not operate spray gun system without a functional inlet pressure gauge� See pressure

recommendations in user’s manual for each spray gun atomizing head�

- Ensure air and liquid input pressure and all applicator system regulators are properly adjusted

per material’s recommendations prior to each use� Do not exceed working pressure per

user’s manual�

- Always follow required air and liquid pressure relief procedures for relieving air and liquid

pressure from the spray equipment�