The 3M™7500 Series half mask can be used with a variety of different

filter/product options:

3M™Gas an vapour filters – All the 6000 Series filters

listed overleaf fit directly onto the 7500 Series half masks

(e.g 6051, 6055 etc)

3M™Particulate filters – the 2000 Series, 6035 and 6038 filters fit

directly onto the 7500 Series half masks.

The 5911 / 5925 / 5935 particulate filters can only be used on their

own if used with the platform 603 & retainer 501.

A combination of gas / vapour an particulate filters – the 5911 /

5925 / 5935 particulate filters can be used with the 6000 series gas /

vapour filters (except 6096) using retainer 501.

Note: The 6098 or 6099 filters should not be used with 7500 series half

masks.

Approvals

The 7500 Series half masks and 6000 / 5000 / 2000 Series filters have

been shown to meet the Basic Safety Requirements under Article 10

and 11B of the European Community Directive 89/686, and are thus CE-

marked.

Approval body for the facepieces:

BSI identification number 0086

Body involved in Quality Assurance Assessment:

BSI identification number 0086

Materials

●Facepiece silicone rubber

●ead harness & low density polyethylene,

straps polyester fibre &

neoprene elastic

●ead harness yoke polybutylene terephthalate

& filter holder (PBT)

●Neck strap loop polypropylene

●Neck strap hook polypropylene

●Exhalation valve silicone rubber

●Inhalation valves silicone rubber

Maximum product weight – 139 grams

Standards

These products have been tested to the relevant European Standards as

shown below:

Facepiece EN140:1998 (7501, 7502 & 7503)

Filter EN141:2000 (6054, 6057, 6059,

6075 & 6096)

EN14387:2004 (6051, 6055)

EN 143:2000 (2125, 2128, 2135,

2138, 5911, 5925, 5935, 6035,

6038)

Correct Usage

●The 7500 Series facepiece, when fitted with 6000 Series gas/vapour

filters may be used in concentrations of gases or vapour (types

specified by 3M) up to 10 times WEL▲or 1000ppm (5000ppm for

6055) whichever value is lower (APF=10)*. Gas / vapour filters

should not be used to protect the wearer against a gas or vapour

that has poor warning properties.

●The 7500 Series facepieces when used with the 5911 filter may

be used in concentrations of solid and aqueous aerosols up to 4

times WEL▲(APF=4)*.

●The 7500 Series facepieces when used with the 5925, 2125 or

2128 filters may be used in concentrations of particulates up to

10 times WEL▲(APF=10)*.

●The 7500 Series facepieces when used with the 5935, 2135,

2138, 6035 or 6038 may be used in concentrations of particulates

up to 20 times WEL▲(APF=20)*.

●The 7500 Series facepieces when used with the 2128 and

2138 may be used to protect against ozone up to 10 times

WEL▲(APF=10)* and to offer relief from nuisance odours and

acid gases below the WEL▲.

●The 7500 Series facepieces when used with the 6038 filter may be

used to protect against ydrogen Fluoride gas up to 30ppm and offer

relief from Ozone, Organic Vapours and acid gases below WEL.

*APF = Assigned Protection Factor

▲WEL = Workplace Exposure Limit

Cleaning and Storage

1. Cleaning is recommended after each use. Remove the filters.

2. Clean the facepiece (excluding filters) with 3M™105 Face Seal

Cleaners or by immersing in warm cleaning solution, water

temperature not to exceed 50°C and scrub with soft brush until

clean. Add neutral detergent if necessary. Do not use cleaners

containing lanolin or other oils.

3. Rinse in fresh, warm water and air dry in a non-contaminated

atmosphere.

4. Respirator components, especially exhalation valve and seat,

should be inspected prior to each use. Any damaged or

deteriorated components should be replaced.

5. The cleaned respirator should be stored away from

contaminated areas when not in use.

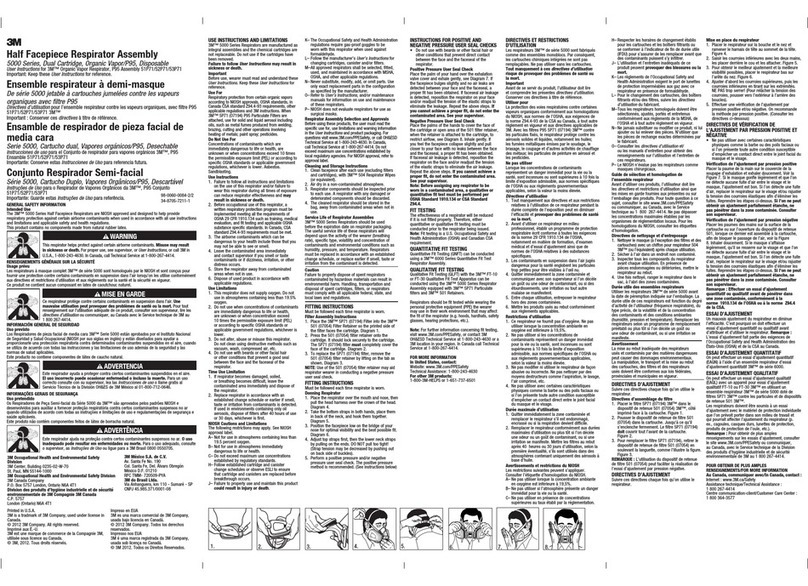

Fitting Instructions

Fitting instructions must be followed each time the respirator is worn.

Stan ar Suspension

1. Adjust head cradle size to fit comfortably on head.

2. Place the respirator over the mouth and nose.

3. Pull the head harness over the crown of the head.

Drop Down Suspension

1.