12

WWARNING

This product is part of a system that helps protect against certain airborne contaminants. Before use, the wearer must read

and understand the User Instructions provided as a part of the product packaging. A written respiratory protection program

must be implemented meeting all the requirements of OSHA 29 CFR 1910.134 including training, t testing, and medical

evaluation. In Canada, CSA standards Z94.4 requirements must be met and/or requirements of the applicable jurisdiction,

as appropriate. Misuse may result in sickness or death.

FOREWORD

Contact Information

Read all instructions and warnings before using. Keep this User Instructions for reference. If you have questions regarding these products

contact 3M Technical Service.

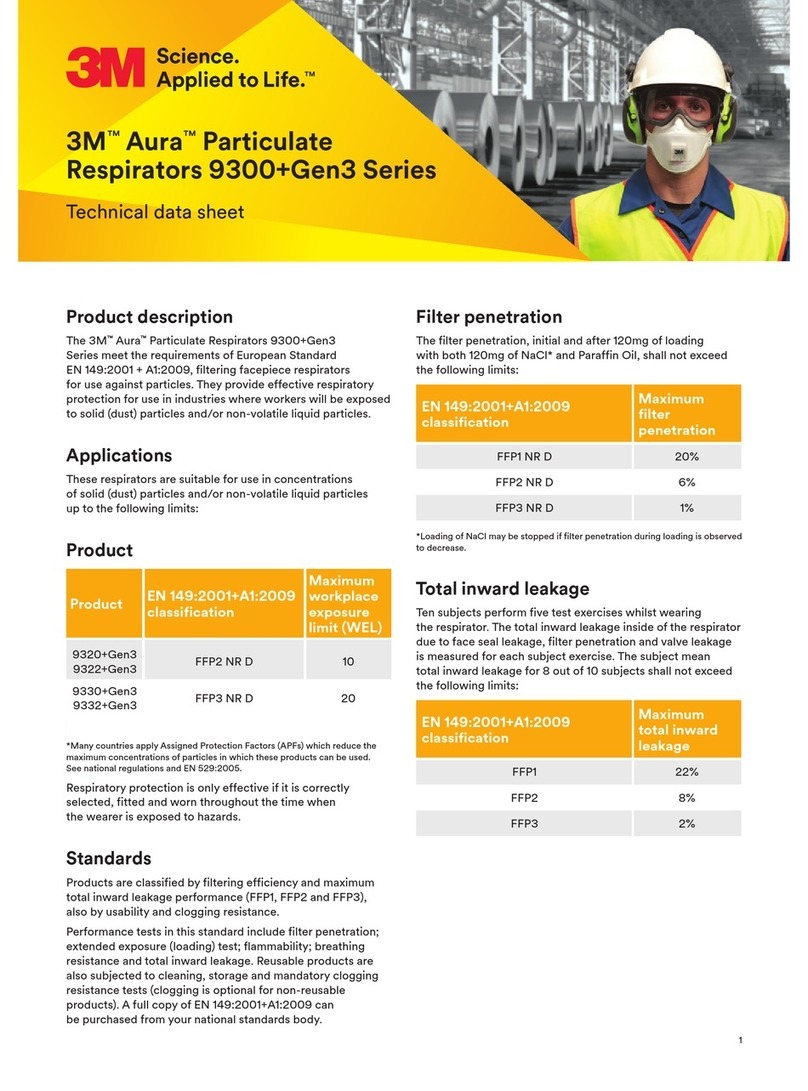

System Description

The 3M™ GVP Powered Air Purifying Respirator (PAPR) Assembly is designed to be used with certain 3M respiratory headgear, lter/cartridges,

batteries and breathing tubes to form a complete NIOSH approved respiratory system. When used in accordance with its NIOSH approval, these

systems help provide respiratory protection against certain airborne contaminants. See “NIOSH Approval” section of this User Instructions for

additional information on approvals.

The GVP belt mounted assemblies consist of a blower unit, lter/cartridge, waist belt and either GVP-111 nickel cadmium, BP-15 nickel metal

hydride battery pack or TR-630 lithium-ion battery. The TR-659 battery adapter and either the TR-656 or TR-657 holster are required when the

TR-630 battery is used with the GVP PAPR assembly.

NOTE: The BC-210 charger, used to charge the BP-15 battery pack, was discontinued and is no longer available.

The GVP assembly used with the GVP-111 battery pack is an intrinsically safe system for the following: Division 1, Class I; Group D, Class II,

Groups E, F, G and Class III. The GVP assembly used with the BP-15 or with the TR-630 battery pack is not an intrinsically safe system.

The motor/blower unit (i.e. turbo assembly) draws ambient air through the lter/cartridge and provides ltered air to the headgear via the

breathing tube. The GVP-111, BP-15 and TR-659 adapter (when used with the TR-630 battery) have a visual alarm to alert the wearer to a low

battery voltage state.

The 3M™ GVP Assembly is available with a variety of accessories and belt options. Consult the “Listing of Components,Accessories and

Replacement Parts” in this User Instructions for additional information including a listing of 3M™ GVP PAPR part numbers. Refer to the

enclosed 3M™ GVP NIOSH Approval Label for approved system congurations.

Use the 3M™ Spark Arrest Cover GVP-146 to help reduce exposure of the 3M™ Motor Blower GVP-100 and 3M™ GVP Cartridges or Filters to

sparks and other hot materials, typically resulting from grinding, welding operations or other “hot work”.

NOTE: The 3M™ Vinyl Belt GVP-117 should not be used for high heat or spark producing operations.

Listing of Warnings and Cautions within these User Instructions

WWARNING

• These respirators help protect against certain airborne contaminants. Before use, the wearer must read and understand the User

Instructions provided as a part of the product packaging. A written respiratory protection program must be implemented meeting all the

requirements of OSHA 29 CFR 1910.134 including training, fit testing, and medical evaluation. In Canada, CSA standards Z94.4

requirements must be met and/or requirements of the applicable jurisdiction, as appropriate. Misuse may result in sickness or

death.

• Each person using this respirator assembly must read and understand the information in these User Instructions before use. Use of

these respirators by untrained or unqualified persons, or use that is not in accordance with these User Instructions, may adversely

affect respirator performance and result in sickness or death.

• Do not use with parts or accessories other than those manufactured by 3M as described in these User Instructions or on the NIOSH

Approval Label for this respirator. Do not attempt to repair or modify any component of the system except as described in these User

Instructions.Failure to do so may adversely affect respirator performance and result in sickness or death.

• Always correctly use and maintain the lithium-ion battery packs. Failure to do so may cause fire or explosion or could adversely

affect respirator performance and result in injury, sickness, or death.

a. Do not charge batteries with unapproved chargers, in enclosed cabinets without ventilation, in hazardous locations, or near sources

of high heat.

b. Do not immerse without the battery storage and cleaning cover installed.

c. Do not use, charge, or store batteries outside the recommended temperature limits.

d. Charge in an area free of combustible material and readily monitored.

• To reduce exposure to hazardous voltage:

a. Do not attempt to service the chargers. There are no user-serviceable parts inside.

b. Do not substitute, modify or add parts to the chargers.

c. Inspect the chargers and power cords before use. Replace if any parts are damaged.

d. Do not use the chargers outdoors or in wet environments.

• Be certain that the filter and/or cartridge that you are placing on the unit is appropriate for the contaminants to which you will be

exposed. Failure to do so may result in sickness or death.

• Do not over-tighten filter/cartridge. Over-tightening may result in distortion or displacement of the seal and may allow contaminated air

to enter the respirator headpiece and may result in sickness or death.

• Failure to pass a user performance check and complete all necessary repairs before use may adversely affect respirator

performance and result in sickness or death.

WWARNING

• Before using a 3M™ GVP PAPR Assembly, each person must read and understand the information in these User Instructions and

the User Instructions provided with the respirator headpiece to be used. Use of these respirator systems by untrained or unqualied

persons, or use that is not in accordance with these instructions, may adversely affect respirator performance and may result in

sickness or death.

• Use of this respirator in atmospheres for which it was not NIOSH certied and designed may result in sickness or death. Do not wear

this respirator where:

a. Atmospheres are oxygen decient.

b. Contaminant concentrations are unknown.

c. Contaminant concentrations are immediately dangerous to life or health (IDLH).

d. Contaminant concentrations exceed the maximum use concentration determined using the assigned protection factor (APF)

recommended for the applicable headpiece or the APF mandated by specic government standards, whichever is lower. Refer to the

User Instructions provided with the applicable headpiece.

• Do not enter a contaminated area until properly donning the respirator system. Do not remove the respirator before leaving the

contaminated area. Doing so may result in sickness or death.

• Contaminants that are dangerous to your health include those that you may not be able to see or smell. Leave the contaminated area

immediately if any of the following conditions occur. Failure to do so may result in sickness or death.

a. Airow decreases or stops.

b. Any part of the system becomes damaged.

c. Airow into the respirator decreases or stops.

d. Breathing becomes difcult.

e. You feel dizzy or your vision is impaired.

f. You taste or smell contaminants.

g. Your face, eyes, nose or mouth become(s) irritated.

h. You suspect that the concentration of contaminants may have reached levels at which this respirator may no longer provide adequate

protection.

• Do not expose blower/lter assembly directly to sparks or molten metal spatter. Direct contact with sparks or molten metal spatter may

damage the lter, allowing unltered air into the breathing zone and may cause the lter or blower assembly to ignite, resulting in

serious injury, sickness or death.

• Never alter or modify this respirator. Repair or replace parts only with the 3M components approved for this assembly. Failure to do so

may adversely affect product performance and result in sickness or death.

• Do not clean respirator with solvents. Cleaning with solvents may degrade some respirator components and reduce respirator

effectiveness. Inspect all respirator components before each use to ensure proper operating conditions. Failure to do so may result in

sickness or death.

• Never attempt to clean lters by knocking or blowing out accumulated material. This may result in damage to the lter membrane

allowing hazardous particles to enter the breathing zone, resulting in sickness or death.

• To reduce the risks associated with re, explosion, and environmental contamination:

Do not dispose of Li-ion batteries in a re or send for incineration. Battery packs should be treated as special waste and in accordance

with your local environmental regulations.

CAUTION

• The 3M™ GVP when used with the BP-15 battery pack or the TR-630 and TR-659 battery/adapter combination IS NOT an

intrinsically safe system.

• 3M™ Motor Blower GVP-100, 3M™ Power Cord GVP-110 and 3M™ Battery Pack GVP-111 combination has been tested and

classied by UL for intrinsic safety for the following: Division 1, Class I; Group D, Class II, Groups E, F, G and Class III. If the GVP-111

battery case is compromised or cracked, or if the rubber switch boot is damaged or missing, the battery pack and system should no

longer be considered intrinsically safe.

• To reduce the risks associated with hot surfaces:

- Do not touch pins after battery has been charged.

LIMITATIONS OF USE

Do not wear this respirator system to enter areas where:

• Atmospheres are oxygen decient.

• Contaminant concentrations are unknown.

• Contaminant concentrations are Immediately Dangerous to Life or Health (IDLH).

• Contaminant concentrations exceed the maximum use concentration (MUC) determined using the Assigned Protection Factor (APF) for the

specic respirator system or the APF mandated by specic government standards, whichever is lower.

Refer to the User Instructions provided with the applicable headgear and the additional cautions and limitations under the “NIOSH Cautions and

Limitations” in this User Instructions.

RESPIRATOR PROGRAM MANAGEMENT

Occupational use of respirators must be in compliance with applicable health and safety standards. By United States regulation employers

must establish a written respirator protection program meeting the requirements of the Occupational Safety and Health Administration (OSHA)

Respiratory Protection standard 29 CFR 1910.134 and any applicable OSHA substance specific standards.Consult an industrial hygienist or call

3M Technical Service with questions concerning applicability of these products to your job requirements.

APPROVAL, CAUTIONS & LIMITATIONS

NIOSH Approval

The GVP PAPR assembly is one component of a NIOSH approved respiratory system. Refer to the User Instructions and/or the NIOSH Approval

Label provided with the GVP PAPR assembly for a listing of components that can be used to assemble a complete NIOSH approved respirator

system or contact 3M Technical Service.