GroundFlex™ Adapter Model 6474

5

1.4 Ordering Information

NOTE: The GroundFlex™ Adapter Model 6474 is a factory supplied product

and only operates with the Ground Tester Model 6472 Kit - 500 ft.

GroundFlex™ Adapter Model 6474...............................................Cat. #2136.01

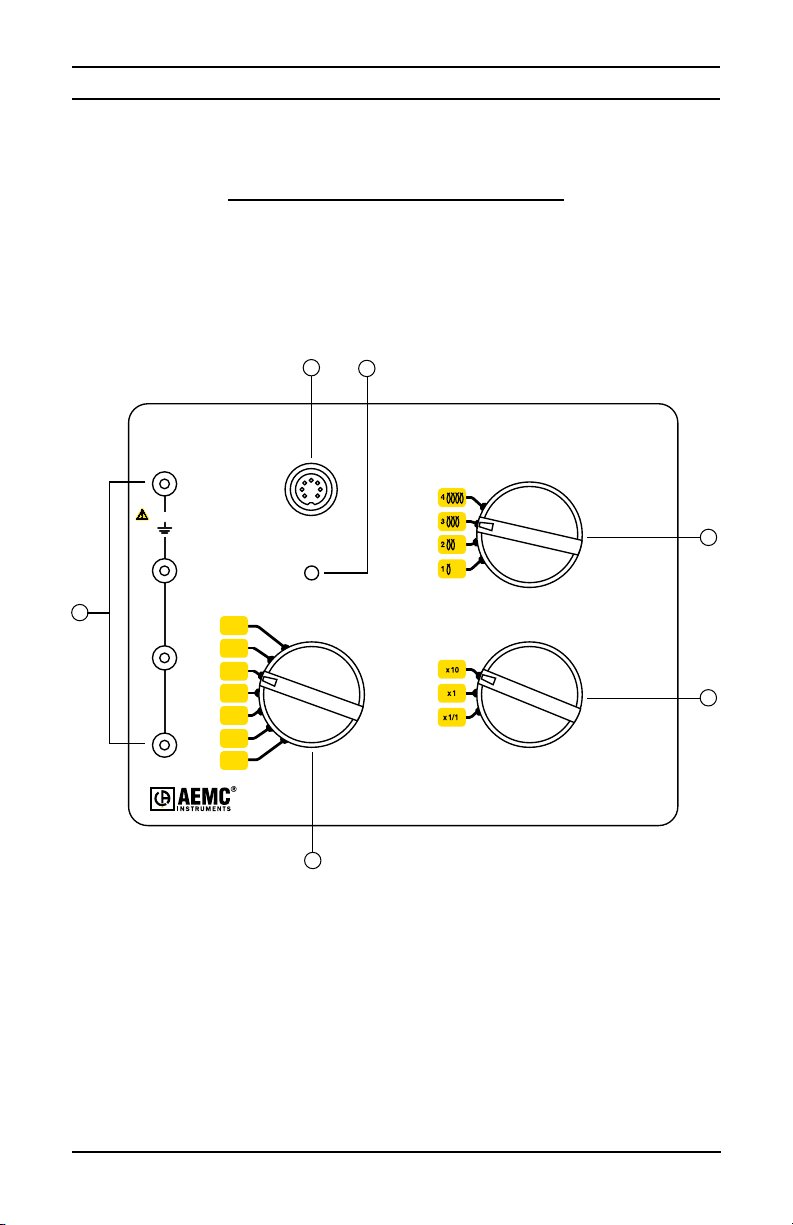

Includes the GroundFlex™ Adapter Model 6474, four GroundFlex™ sensors (5m/16ft) with

twelve color-coded rings, connection lead, two extension leads on H reel (black/green) with

color-coded alligator clips, six BNC extension leads, calibration loop, three C-clamps, carrying

case for meter and a user manual.

GroundFlex™ Field Kit (Model 6472 and 6474) ...........................Cat. #2136.03

Includes the GroundFlex™ Adapter Model 6474 (Cat. #2136.01 above), Ground Resistance

Tester Model 6472, rechargeable NiMH batteries, optical USB cable, power adapter 110/240V

with power cord 115V US, two 500 ft color-coded leads on spools (red/blue), two 100 ft color-

coded leads (hand-tied, green/black), one 30 ft lead (green), four T-shaped auxiliary ground

electrodes, set of ve spaded lugs, one 100 ft AEMC®tape measure, DataView®software,

ground tester workbook CD, carrying bag for meter, carrying bag for kit, hard carrying case,

product warranty and registration card and a user manual.

1.4.1 Accessories and Replacement Parts

Bag#6-CarryingBagforGroundKits............................................. Cat. #2119.82

TapeMeasure-AEMC®(100ft) .......................................................Cat. #2130.60

GroundTesterDVD/WorkbookSet...................................................Cat. #2130.64

Setoftwo,14.5"T-shapedAuxiliaryGroundElectrodes..................Cat. #2135.39

OpticalUSBCable............................................................................Cat. #2135.41

Replacement-OneGroundFlex™(5m /16ft)Sensor.......................Cat. #2135.73

Replacement-ConnectionLeadforModel6472/6474....................Cat. #2135.75

Replacement-OneBNC(15m/50ft)ExtensionLead......................Cat. #2135.76

Replacement-Setof12,GroundFlex™Rings

(red,yellow,brown,orange) .............................................................Cat. #2135.77

Replacement-GreenExtensionLead .............................................Cat. #2135.78

Replacement-BlackExtensionLead...............................................Cat. #2135.79

Replacement-Setof3,C-clamps....................................................Cat. #2135.80

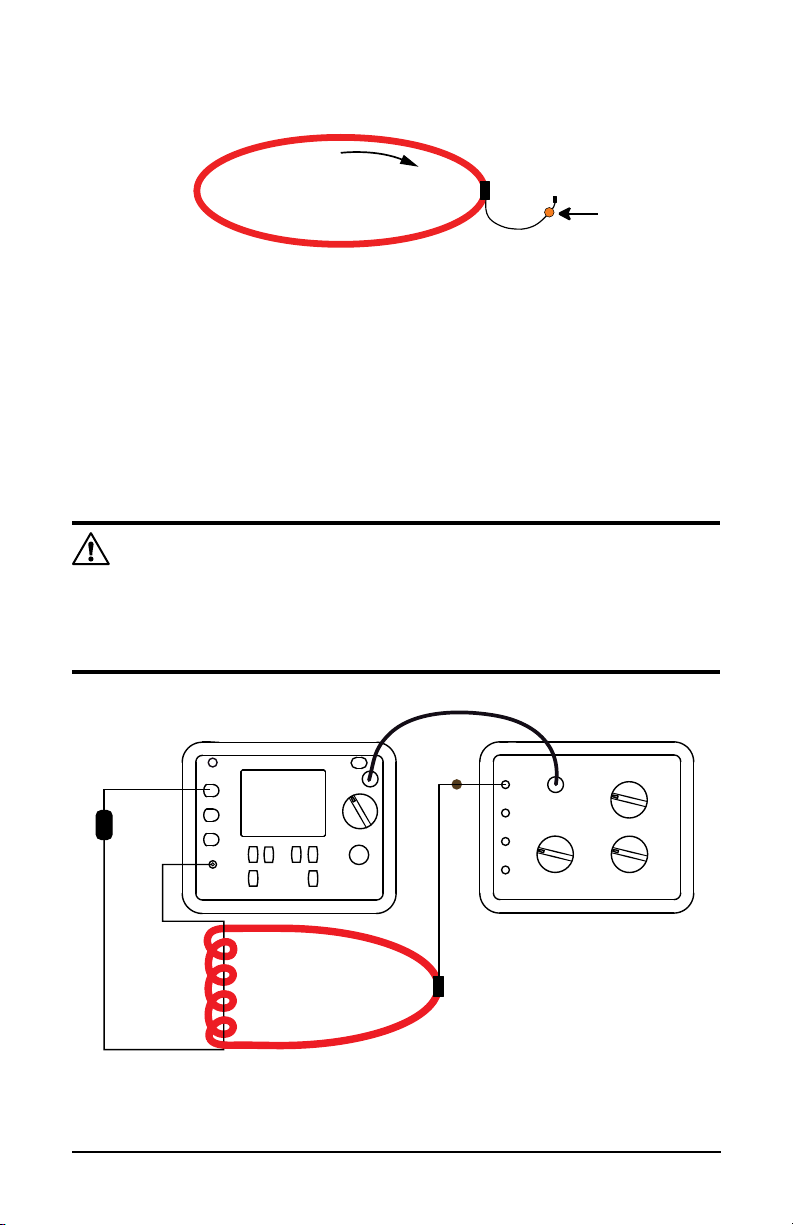

Replacement-CalibrationLoop.......................................................Cat. #2135.82

Replacement-CarryingCase ..........................................................Cat. #2135.83

Replacement-SafetyAlligatorClip(black) ......................................Cat. #2140.53

Replacement-SafetyAlligatorClip(green) .....................................Cat. #2140.69

Order Accessories and Replacement Parts Directly Online

Check our Storefront at www.aemc.com/store for availability