8

MiniFlex

®

Flexible AC Current Probe

CHAPTER 3

SPECIFICATIONS

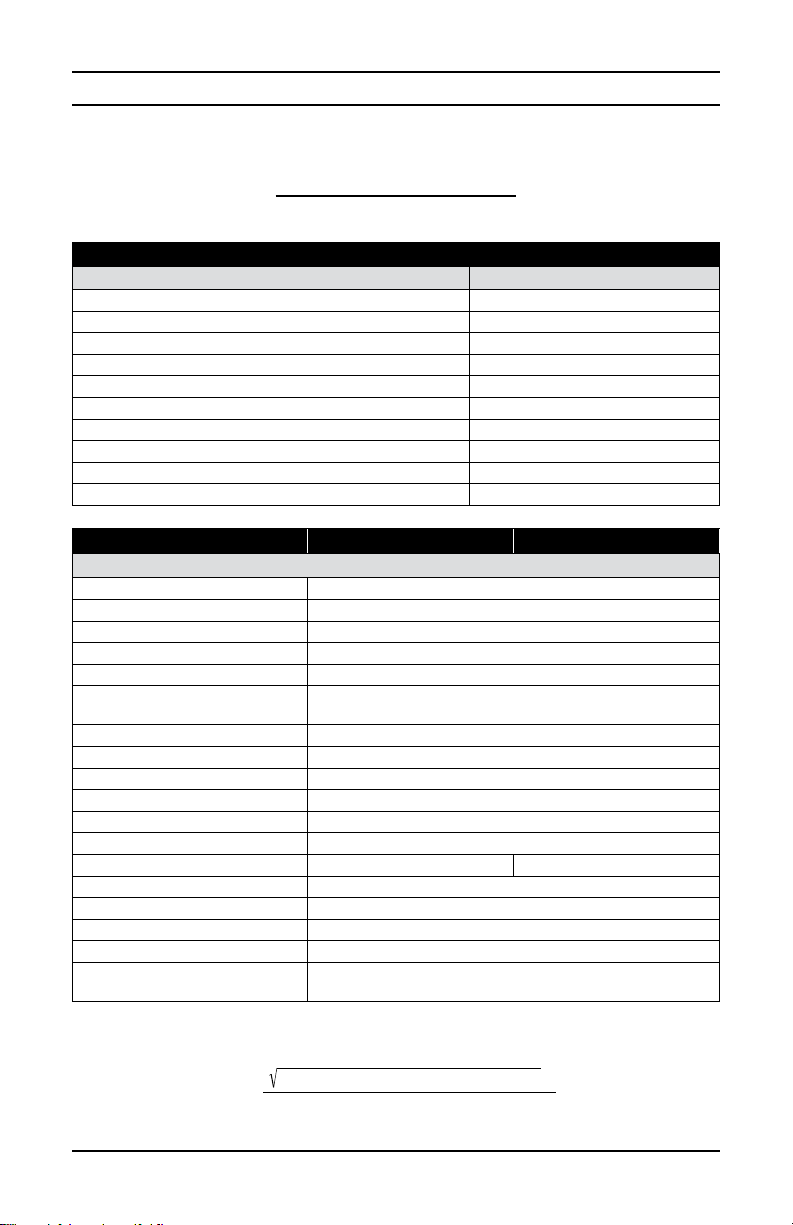

REFERENCE CONDITIONS

Quantity of influence Reference values

Temperature 23 ± 5° C

Relative humidity 20 to 75% RH

Frequency of the signal measured 40 to 400Hz

Type of signal Sinusoidal

External electric field < 1V/m

External DC magnetic field (earth field) < 40A/m

External AC magnetic field None

Position of the conductor Centered in the measurement coil

Shape of the measurement coil Nearly circular

Input impedance of the display device connected to housing ≥1MW

MODEL MF 300-6-2-10-HF MF 300-10-2-10-HF

ELECTRICAL

Range 30/300A

Signal Output 100mV/10mV/A

Frequency Range 5Hz to 1MHz @ -3db

Frequency Limitation none

Influence Of Conductor Positioning 1.5% typical, 3% max

Influence Of Conductor Positioning

In Sensor Against Handle 4% typical, 6% max

External Conductor Influence 35dB to 40dB on contact

Accuracy ± 1% +0.3A

Common Mode Rejection 100dB typical, 80dB min

Max peak factor (1) at I nominal 1.5

Residual noise at I = 0 (Arms) (2) 0.3A

Max phase shift at 1kHz (°) 1

Max offset voltage (mVDC)50 5

Max output voltage (Vpeak) ± 4.5

Output impedance (kW)1

Power Source 9V alkaline battery (6LF22)

Battery Life 140 hrs continuous operation or 10,000 one minute measurements

Battery Indicator When Green LED starts blinking, remaining life is approx 8 hours;

When LED is OFF, the battery needs to be replaced

(1):PeakfactorPF=Vpeak/Vrms

(2):Theresidualnoiseaffectsthemeasurementuncertaintyaccordingtotheformula:

(I measured x 0.01)2+ (residual noise)2

global uncertainty = (I measured ≠ 0)

Ifthecurrentmeasurediszero,theuncertaintyisequaltotheresidualnoise.