Seite | 5

- Lock the workpiece by closing the clamping lever.

- Swing down the hold-down device and clamp in vertical position

- The foot switch must be operated and held for punching.

The cylinder piston stops as soon as the foot switch is released.

- Do not use blunt or damaged tools.

- The working area must always be kept clean and free of chips.

- The punching process can be interrupted immediately by releasing the foot pedal.

The cylinder piston stops immediately!

- Never reach into the punching area between die, workpiece and punch during the punching

process!

- The punching operation may only be carried out with the hold-down device completely folded

down and secured!

- Worn and damaged tools can cause damage to the punching unit.

- Laser acc Laser class 2, DIN EN 60825-1

Class 2 lasers are lasers in the visible range and in which an irradiation of less than

0.25 ms is harmless to the eye 0.25 ms correspond to an eyelid closure reflex,

which automatically protects the eye sufficiently against prolonged irradiation.

Do not look into the laser beam!

- The machine may only be operated by persons who are not under the influence of medication/

other substances which impair the perception, reaction time of all body functions, as well as motor

skills.

To obtain an optimum punching result and reduce tool wear, we recommend cleaning and rubbing

the punches and dies regularly with a cloth and conventional oil, especially the cutting edges.

The function and setting options of the optionally available digital measuring system can be found in the

operating instructions, which are enclosed in this case.

7. Maintenance and care

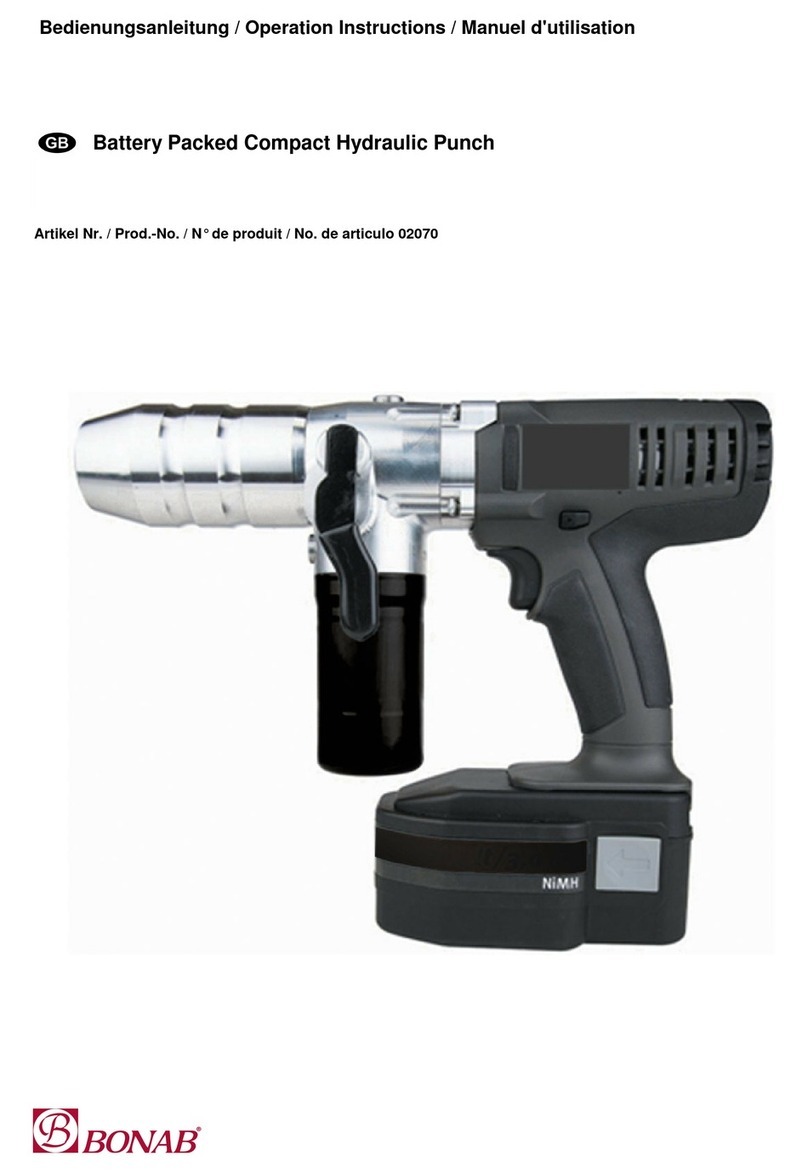

- The hydraulic unit may only be operated with branded hydraulic oil, viscosity class HLP 32.

- Ensure sufficient oil level and cleanliness of the oil.

- Carry out the first oil change after approx. 500 operating hours, each subsequent oil change after

every

5000 operating hours, but at the latest after every 2 years.

- After the first 50 hours of operation, all hydraulic fittings must be checked for leaks and retightened if

necessary.

- Always ensure that the guide shafts and ball bearings are clean.

- In the event of electrical malfunctions, the punch can no longer be put into operation and must be

secured accordingly.

Re-commissioning only after inspection and repair by qualified personnel with the aid of the circuit

diagrams and corresponding release.

- The pressure relief valve has been set at the factory.

It can be checked with the aid of the pressure gauge.

The external hydraulic hoses should be replaced after 6 years of operation.

ECDeclarationofConformity