8

MAINTENANCE

A. TipMaintenance

1.TipTemperature

High temperature shortens tip life andmay cause thermal shock to components.

Alwaysusethelowestpossibletemperaturewhensoldering.Theexcellentthermal

recovery characteristics of the 2901 station ensures effective soldering at low

temperature.

2.Cleaning

Always clean the soldering tip before use to remove any residual solder or flux

adheringtoit. Use acleanandmoistcleaningsponge. Contaminantsonthetip

havemanydetrimentaleffectsincludingreducedheatconductivitywhichcontribute

topoorsolderingperformance.

3.Afteruse

Always cleanthe tip and coat it withfreshsolder after use. This guards against

oxidation.

4.Whentheunitisnotbeingused

Neverallowtheunittostayidleathightemperatureforextendedperiods.Thiswill

allow the tipto become oxidized. Turn the power switch OFF ifit is tobe out of

serviceforseveralhours.Itisadvisabletopullthepowerplugaswell.

5.Inspectingandcleaningthetip

Thisprocedure,iffolloweddailywillmateriallyaddtotiplife.

1.Setthetemperatureto250

o

C.

2.Whenthetemperaturestabilizes,cleanthetipandcheckitscondition.Ifthetip

isbadlywornordeformed,replaceit.

3.Ifthesolderplatedpartofthetipiscoveredwithblackoxide,applyfreshsolder

containingfluxandcleanthetipagain.Repeatuntilalltheoxideisremoved

thencoatthetipwithfreshsolder.

Neverfilethetiptoremoveoxide.

4.TurnthepowerOFFandremovethetipusingtheheatresistantpad.Setthe

tipasidetocool.

5.Remainingoxidessuchastheyellowdiscolorationonthetipshaftcanbe

removedwithisopropylalcohol.

5

SPECIFICATIONS

ASSEMBLYANDPREPARATION

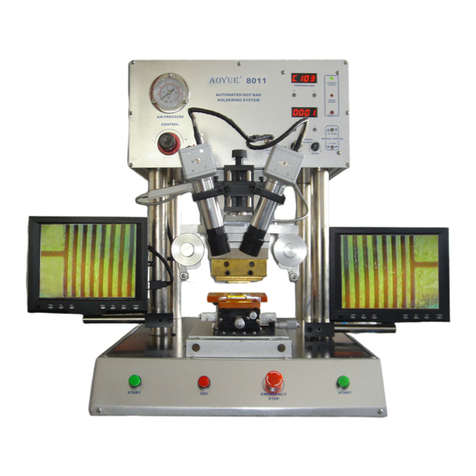

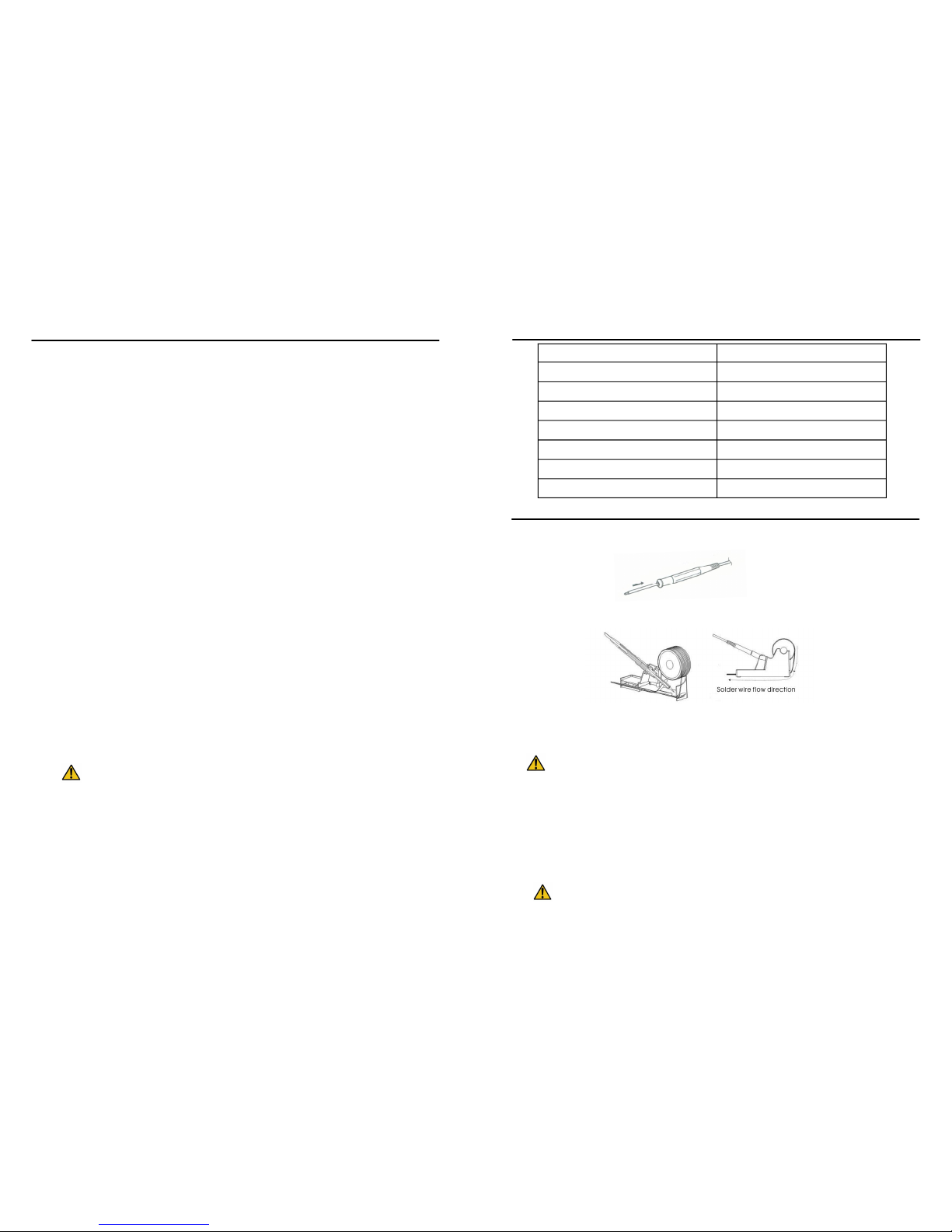

A. Handpiece

Insertthetipfullyintothehandpiece.

B.SolderingIron

1.Installsolderwiretothesolderironholder.

2.Attachthesolderingirontothe5pinoutputatthebottomrightareaofthestation.

3.Placesolderingirontothesolderingironstandasshowninthefigureabove.

Dampen the sponge with water and squeeze dry before using. The tips

maybedamagedwhenusedwithdrysponge.

C.SolderingStation

1.Insertthepowercordintothereceptacleatthebackofthestation.

2.Adjustrequiredvoltagefromtheredswitchatthebackofthestation.

3. Plug the power cord into a grounded wall socket. The station is protected

againstelectrostaticdischargeandmustbegroundedforfullefficiency.

BesurethepowerswitchisOFFbeforeconnectingordisconnectingthe

Powercord.Failuretodosomayresultindamagetothecircuitboard.

PowerInput: 110Vor220Vadjustable

PowerConsumption: 70W

SolderingIronOutputVoltage: 24V

SolderIronTemperatureRange: 200480o

C

TiptoGroundResistance: < 2 W

TiptoGroundPotential: < 2mV

Dimension: 110(w)x90(h)x155(d)mm

Weight: 3Kg