4

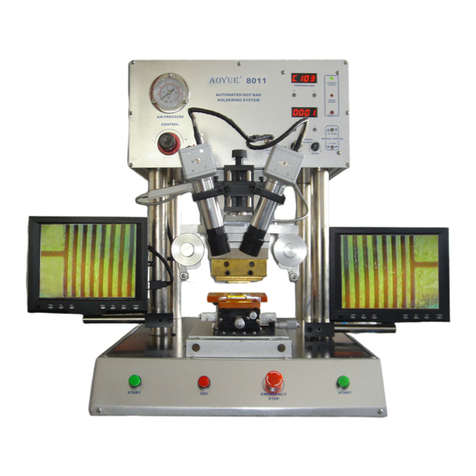

The Aoyue Int732 Game Console RepairingSystem is a reworking equipment

thatutilizesinfrared(IR)heatingtechnology,toprovidetopandbottomheatingto

the target components. It is equipped with a versatile board holder, Lead free

compatiblesolderIron,andsoftwareprofilecontrolofheatinginone sophisticated

package. It is designed for reworking doublesided, diverse technology printed

circuitboards(PCB)whichutilizestraditionalorleadfreesolder.

The system is equippedwith High powered IRheating elements combined

with multiple types of operating mode to fit various task. Finally, the unique,

innovativedesignwithdigitalcontrolpaneloffersprecision,safety,andeaseofuse

tomeetallreworkingrequirements.

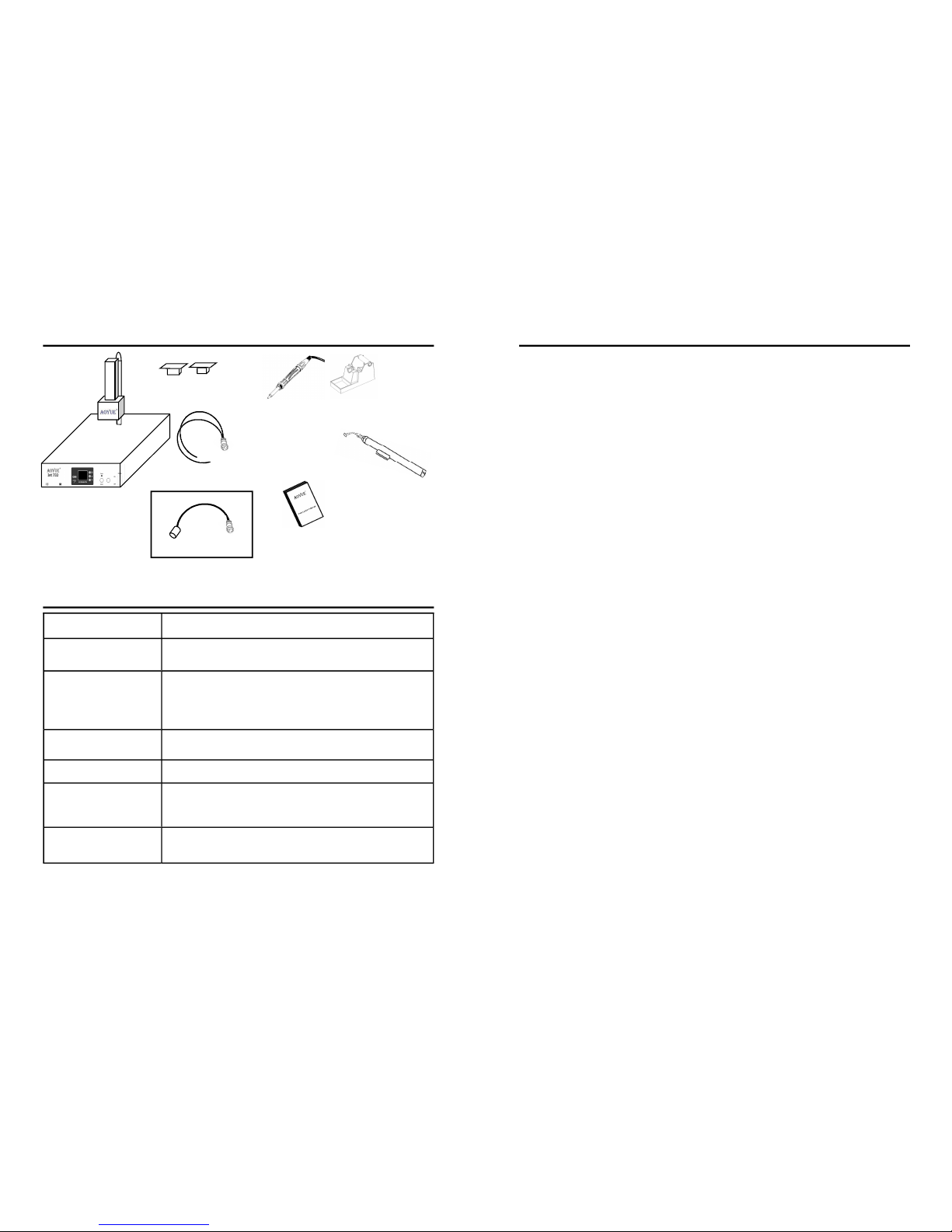

PRODUCT DESCRIPTION

●Complete Game Console Repairing System.Combines large area bottom

heater, high powered topheater andlead free compatible solder iron in one

package.

●Threedifferenttypesofoperationtosuitedifferentneeds:

Type0–Forreballingorprebakingtheboard.Usesinternalsensors.

Type1–Allowsmanualcontrolofthereworkprocess.Usesexternalsensors.

Type2–Automatedreflowingprocessutilizingtheuserconfigurableprofile.

●ClosedLoopTemperatureControlwithThreeExternalSensors

—Sensorsattachedtotheboardallowsprecisetemperaturecontrolatboard

level minimizing damage to board due to inaccurate temperature settings or

overheating. Two sensors are used as temperature control and monitoring,

while an extra sensor is added to allow additional monitoring of other

temperaturesensitiveareasofthePCB.

●EnhancedTopandbottomheater

310x310mmeffectivebottomheatingarea.1500wattsofpreheatingpower

minimizesboardwarping.

60x60mmeffectivetopheatingarea.500wattsmaximumheatingpowerwith

variousnozzlestofitdifferentBGAsizes.

FUNCTIONS and FEATURES

13

OPERATING PROCEDURES

Note: Duringsegments13thetopheaterheatsupto75%ofthesettemperature

at these segments. This is to allow a faster ramp up inpreparation for reflow for

segments46.

1. Toentertype“2”operation.Select2attheinitialscreenthenpresstheselect

button.Thedisplaywouldchangeto“SlctProf 0”.Thissignifieswearenow

inthetype“2”mode.

2. We can then select which profile we would like to use by pressing the

increaseor decrease button. The number shownat the bottom display will

changecorrespondingtoyourselection.Therearethreestoredandselectable

profile.

3. To adjust the time and temperature profile of each segment press the

selectionbuttontwice.Thetopdisplaywillshowwhichsegment“SEG1” we

are currently adjusting. The middle display will show whether we are

adjustingthe“dur” (duration/Time)or“tEMP” (temperature).Thebottom

displayshowsthevaluewearecurrentlyadjusting.Itssuffix“t”signifieswe

areadjustingthetimeortemperatureforasuffix“C”.

4. Press the increase or decrease button to adjust the desired duration and

temperature. The set temperature is adjustable from 50 to 250 C and

duration5to200seconds.

5. Afterthedurationortemperatureissetpresstheselectionbuttontomoveto

the next segment. There are six segments available each with its own

durationandtemperaturesettings.Thedurationsettingssignifiesthetimeit

willtaketoreachoursettemperaturelevel.Forexample:ifsetdurationis50t

andtemperatureissetat100C.Thenassumingtheboardtemperatureis50C

whentheautomatedreworkisinitializedthesystemwouldgraduallyincrease

board temperature by 1 Degree per second such that after 50 seconds the

boardtemperaturewouldreach100C.

6. After we have set the segments of the profile we may begin automated

reworking. To start automation repeatedly press the selection button until

thedisplayshowstheword“Run Prof 0” (thebottomdisplaynumbershould

correspondtotheselectedprofile)thenpresstheincreasebutton.A3second

countdownwillcommencebeforeautomatedreworkingstarts.