MAINTENANCE

4.Whentheunit

is

notbeingusedandtheautosleepmodeshutoff

is

notactive

Never

allowtheunittostayidleathightemperatureforextendedperiods.This

will

allowthetiptobecomeoxidized.Turnthepower

switch

OFFifitistobeoutof

serviceforseveralhours.Itisadvisabletopullthepowerplugaswell.

5.Inspectingandcleaningthe

tip

This

procedure,iffolloweddaily

will

materiallyaddtotip

life.

1.

Setthetemperatureto

250°C.

2.

When

thetemperaturestabilizes,cleanthetipandcheckitscondition.Ifthetip

isbadlywornor

deformed,

replaceit.

3.

Ifthesolderplatedpartofthetipiscovered

with

blackoxide,applyfreshsolder

containing

flux

andcleanthetipagain.Repeat

until

alltheoxideisremoved

thencoatthetip

with

freshsolder.

/$\

Never

file

thetiptoremoveoxide.

4.Turn

thepower

OFF

andremovethetipusingtheheatresistantpad.Setthe

tipasidetocool.

5.

Remainingoxidessuchastheyellowdiscolorationonthetipshaftcanbe

removed

with

isopropylalcohol.

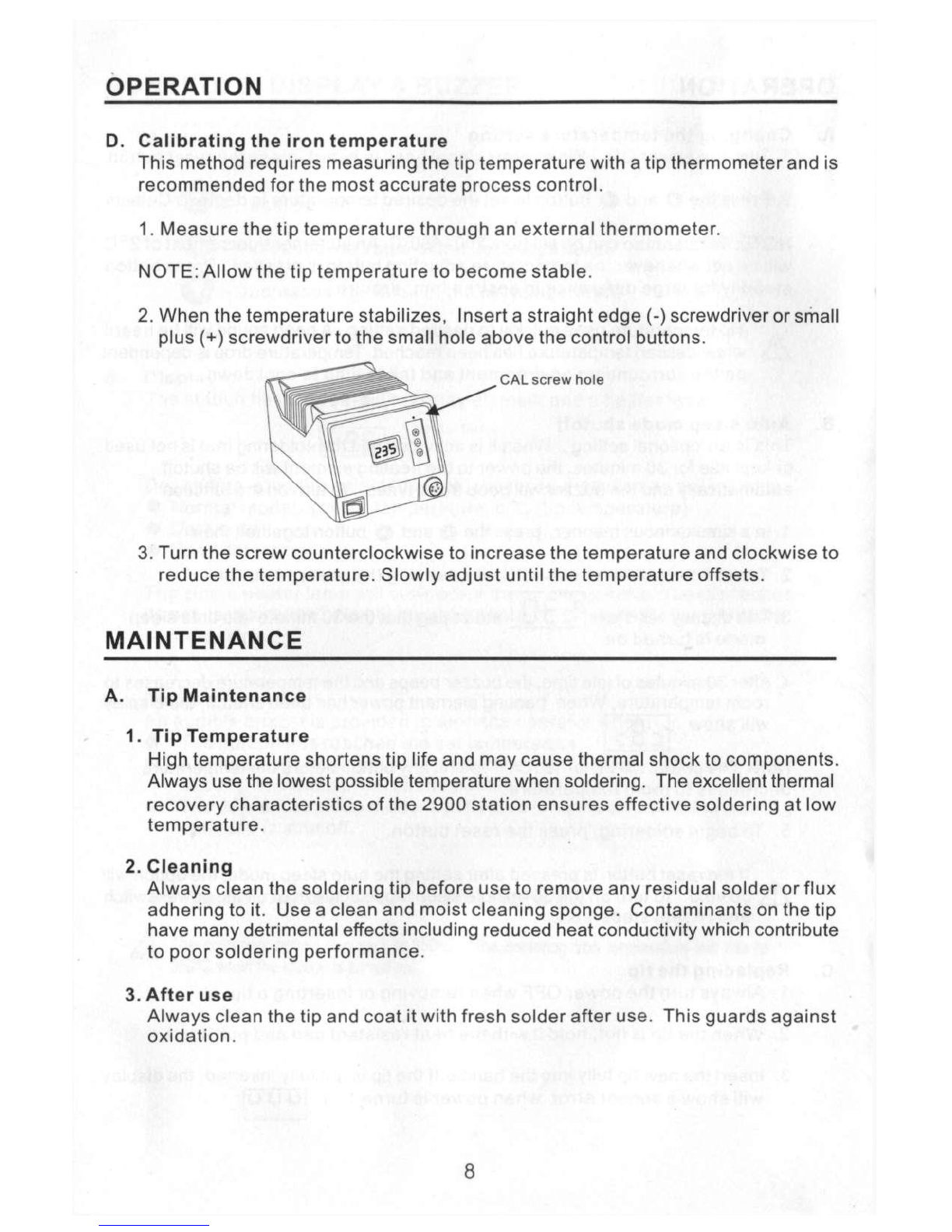

B.CheckingProcedure

Δ

Unless

otherwisedirected,carryouttheseprocedures

with

thepower

switch

OFF

andthepowercord

UNPLUGGED.

•

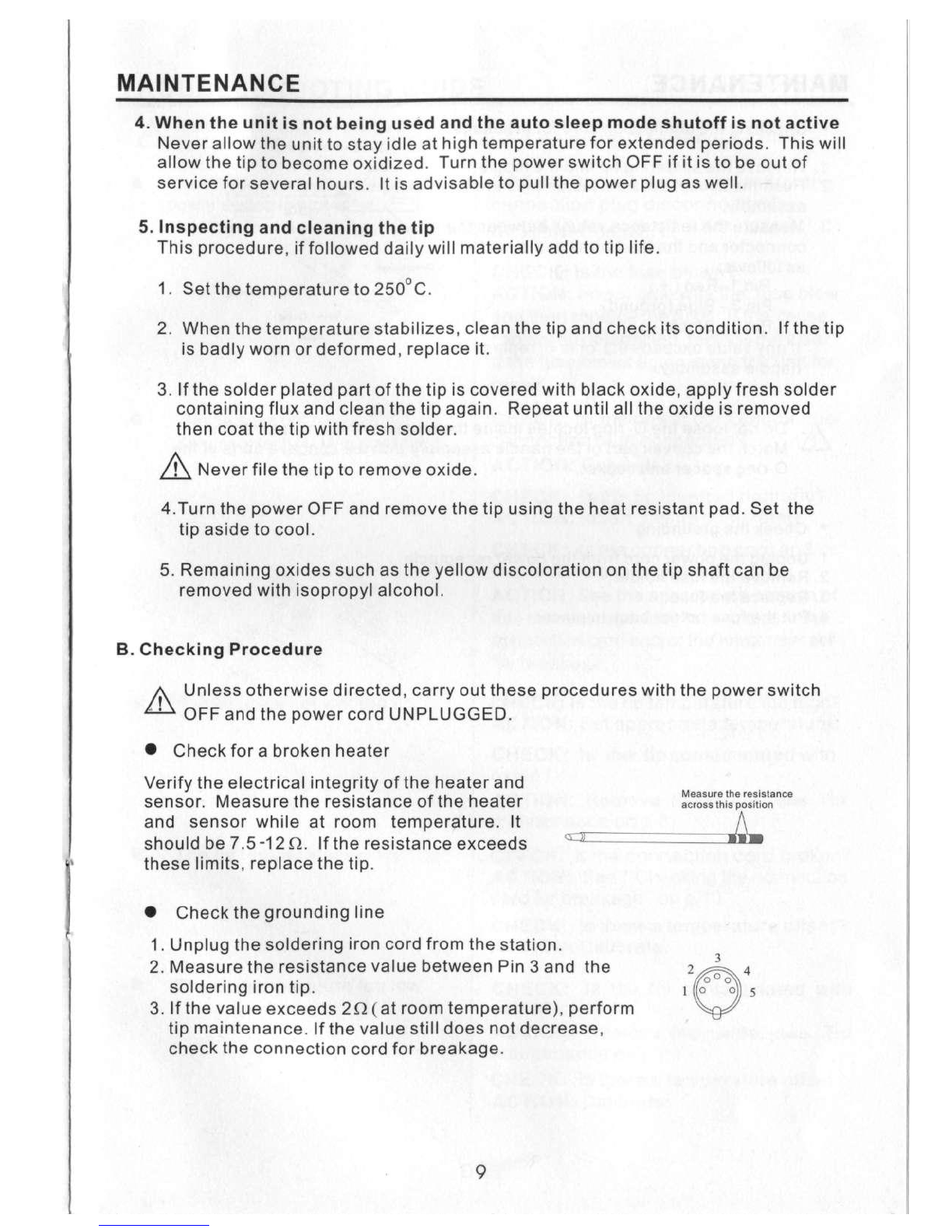

Checkfora brokenheater

Verifythe

electrical

integrity

oftheheaterand

sensor.

Measuretheresistanceoftheheater

and

sensorwhileatroomtemperature.It

should

be

7.5-12Ω.

Iftheresistanceexceeds

these

limits,

replacethetip.

•

Checkthegroundingline

1.

Unplugthesolderingironcordfromthestation.

2.

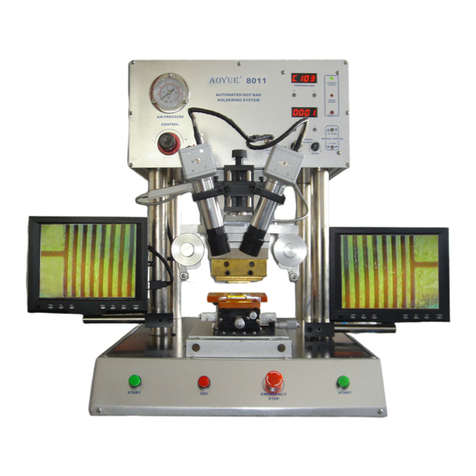

MeasuretheresistancevaluebetweenPin3 andthe

solderingirontip.

3.

Ifthevalueexceeds

2

Ω (atroomtemperature),perform

tipmaintenance.Ifthevalue

still

doesnotdecrease,

checktheconnectioncordforbreakage.

Measure

the

resistance

across

thisposition

9