3

Safety Instructions ...........................................................................5

General .............................................................................................................. 5

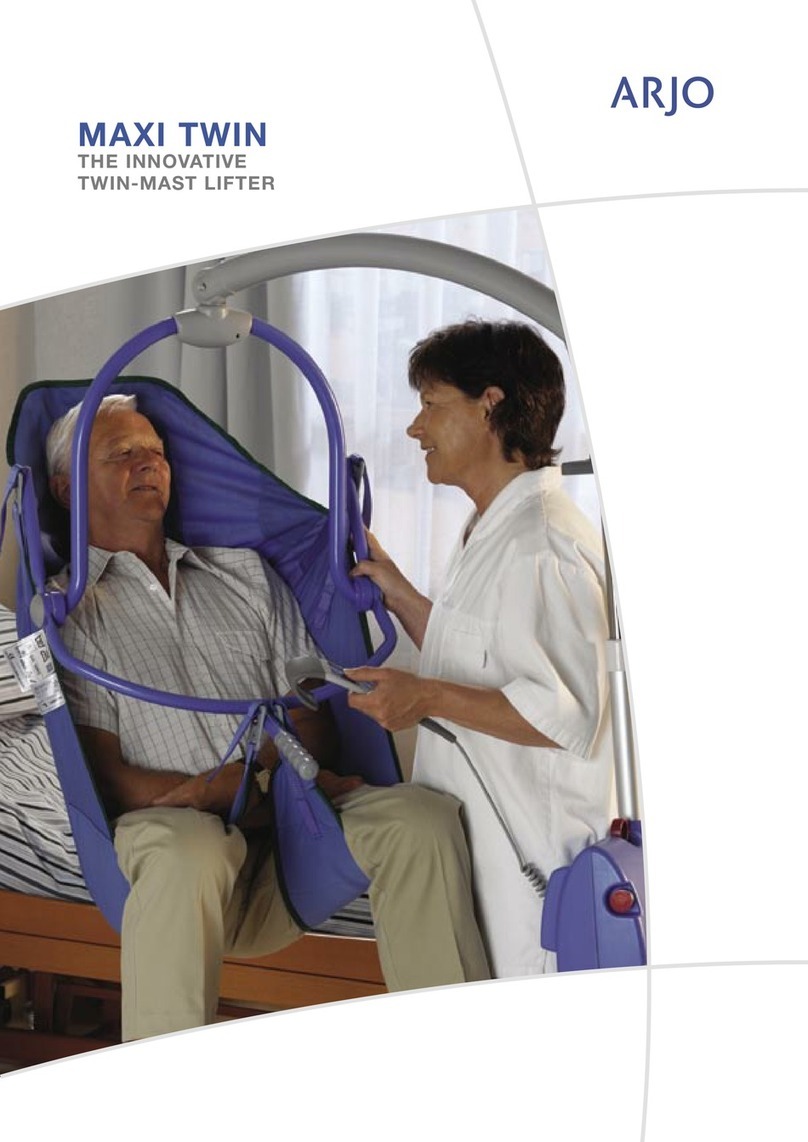

Product and Technical Description ...............................................6

Introduction ....................................................................................................... 6

Features ............................................................................................................. 6

Combi Feature ................................................................................................... 6

Risk Assessment Checklist for Engineers ......................................................... 7

Suggested Tools ................................................................................................ 8

Recommended Spares ....................................................................................... 8

Loctite Application ............................................................................................ 9

Torque Data and Consumable Materials ........................................................... 10

Preventive Maintenance Schedule .................................................12

Service Procedures ..........................................................................17

Procedures not Included in the PMS ................................................................. 17

Service Procedure 1 ........................................................................................... 18

Check that the latest updates have been implemented ................................ 18

Service Procedure 2 ........................................................................................... 19

Check the battery ......................................................................................... 19

Battery test ................................................................................................... 19

Check the battery charger ............................................................................ 20

Service Procedure 3 ........................................................................................... 21

Check all vital parts for corrosion and damage ........................................... 21

Painting ........................................................................................................ 21

Service Procedure 4 ........................................................................................... 22

Full Feature Test .......................................................................................... 22

Service Procedure 5 ........................................................................................... 23

Safe Working Load Test (local Requirement) ............................................. 23

Service Procedure 6 ........................................................................................... 26

Scale Calibration Check .............................................................................. 26

Verified Scale ........................................................................................26

Verified Scale and Non-Verified Scale ................................................. 26

Service Procedure 7 ........................................................................................... 27

Wheel Replacement .....................................................................................27

Front ...................................................................................................... 27

Back ....................................................................................................... 28

Service Procedure 8 ........................................................................................... 29

Changing the Leg Assembly/Actuator ........................................................ 29

Chassis opening ..................................................................................... 29

Legs ........................................................................................................ 29

Legs Actuator .........................................................................................29

Reassembly ............................................................................................30

Service procedure 9 ........................................................................................... 31

Legs opening adjustment ............................................................................. 31

Verification ............................................................................................ 31

Adjustment ............................................................................................. 31

Service Procedure 10 ......................................................................................... 32

Control box (PCB, Fuse, Switch, Keypad) .................................................. 32

Opening the Control box ........................................................................ 32

Fuse change ............................................................................................ 32

Main board changes ............................................................................... 32

DIP Switch Settings ..................................................................................... 34

Configuration procedure ........................................................................ 34

Changing the Brake board ..................................................................... 36

Table of Contents