Arjo Prioma Series User manual

Other Arjo Medical Equipment manuals

Arjo

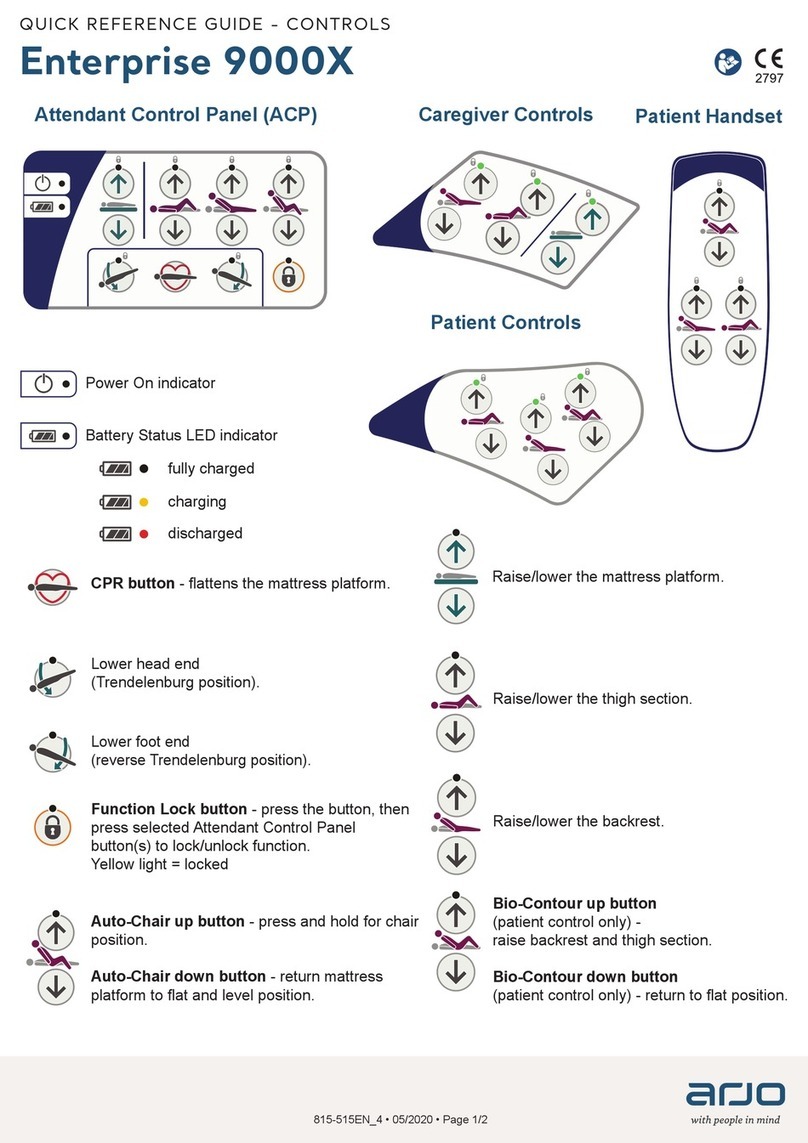

Arjo Enterprise 9000X User manual

Arjo

Arjo MAA8000 User manual

Arjo

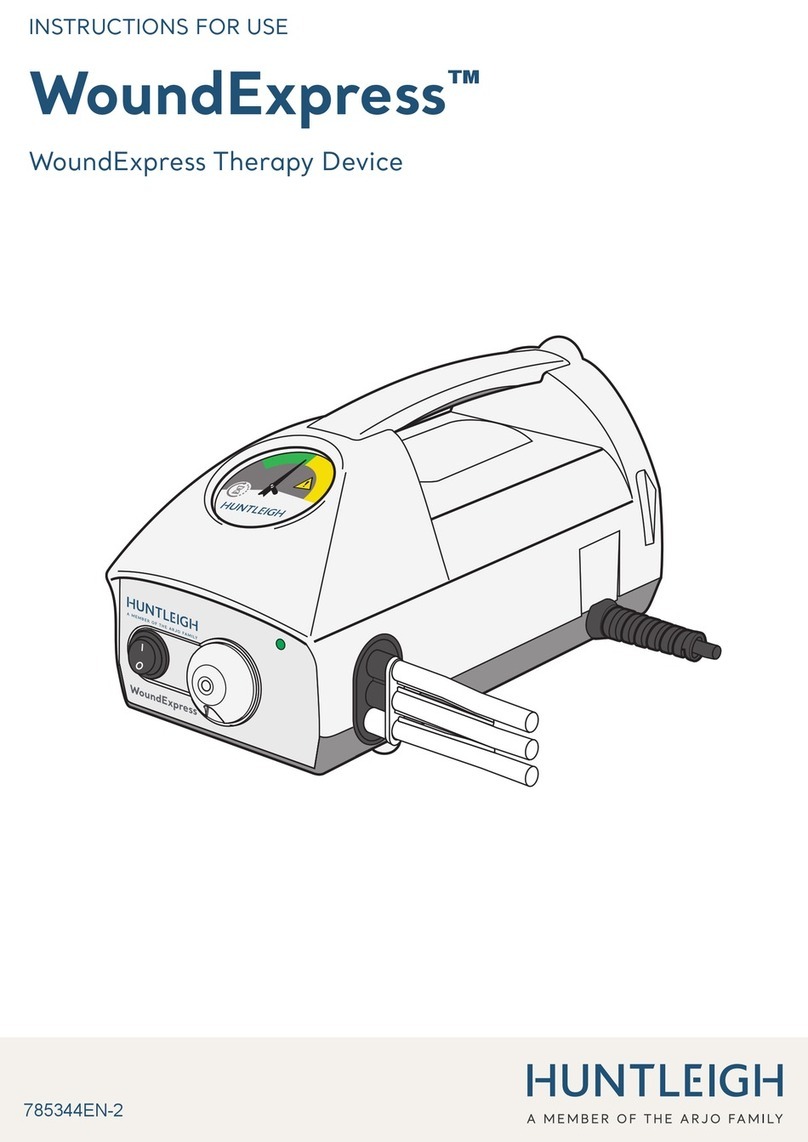

Arjo Huntleigh WoundExpress User manual

Arjo

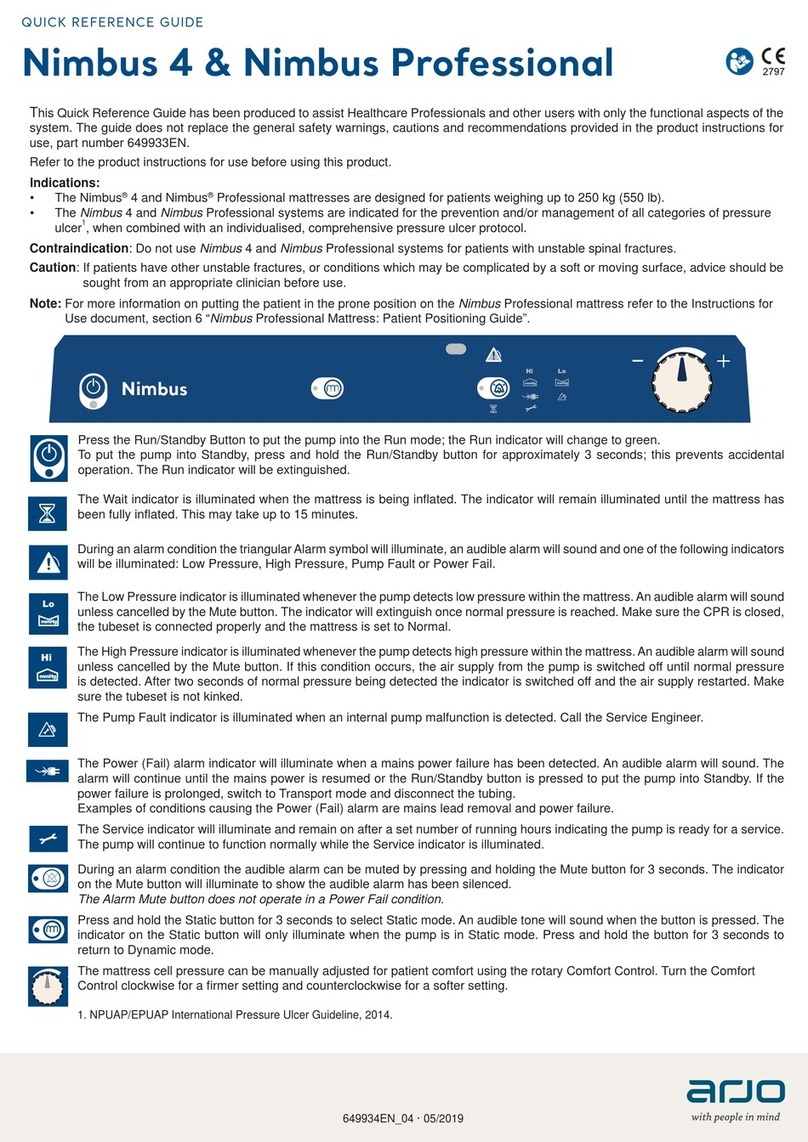

Arjo Nimbus 4 User manual

Arjo

Arjo MAXI MOVE Operating instructions

Arjo

Arjo Typhoon User manual

Arjo

Arjo Auralis User manual

Arjo

Arjo Skin IQ 1000 User manual

Arjo

Arjo Opera Installation guide

Arjo

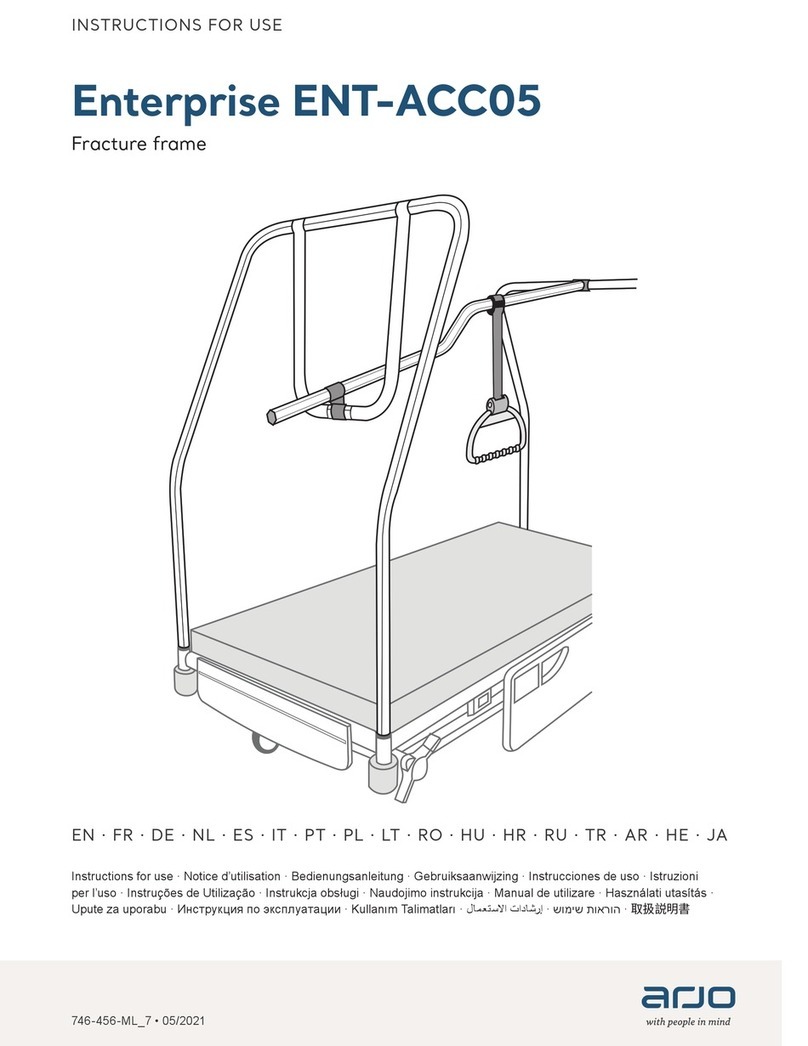

Arjo Enterprise ENT-ACC05 User manual

Arjo

Arjo Dual-Loop Attachment Straps User manual

Arjo

Arjo Huntleigh Dopplex Ability User manual

Arjo

Arjo SARA PLUS Installation guide

Arjo

Arjo Citadel User manual

Arjo

Arjo MAA4020M User manual

Arjo

Arjo Maxi 500 User manual

Arjo

Arjo Enterprise E8000X User manual

Arjo

Arjo Enterprise 9000X User manual

Arjo

Arjo Enterprise ENT-ACC71 User manual

Arjo

Arjo Tornado Instruction manual