5

To activate the water coolant, move the

wet/dry toggle switch on the foot pedal to

the right position. Move the toggle switch

to the left position to disable water coolant.

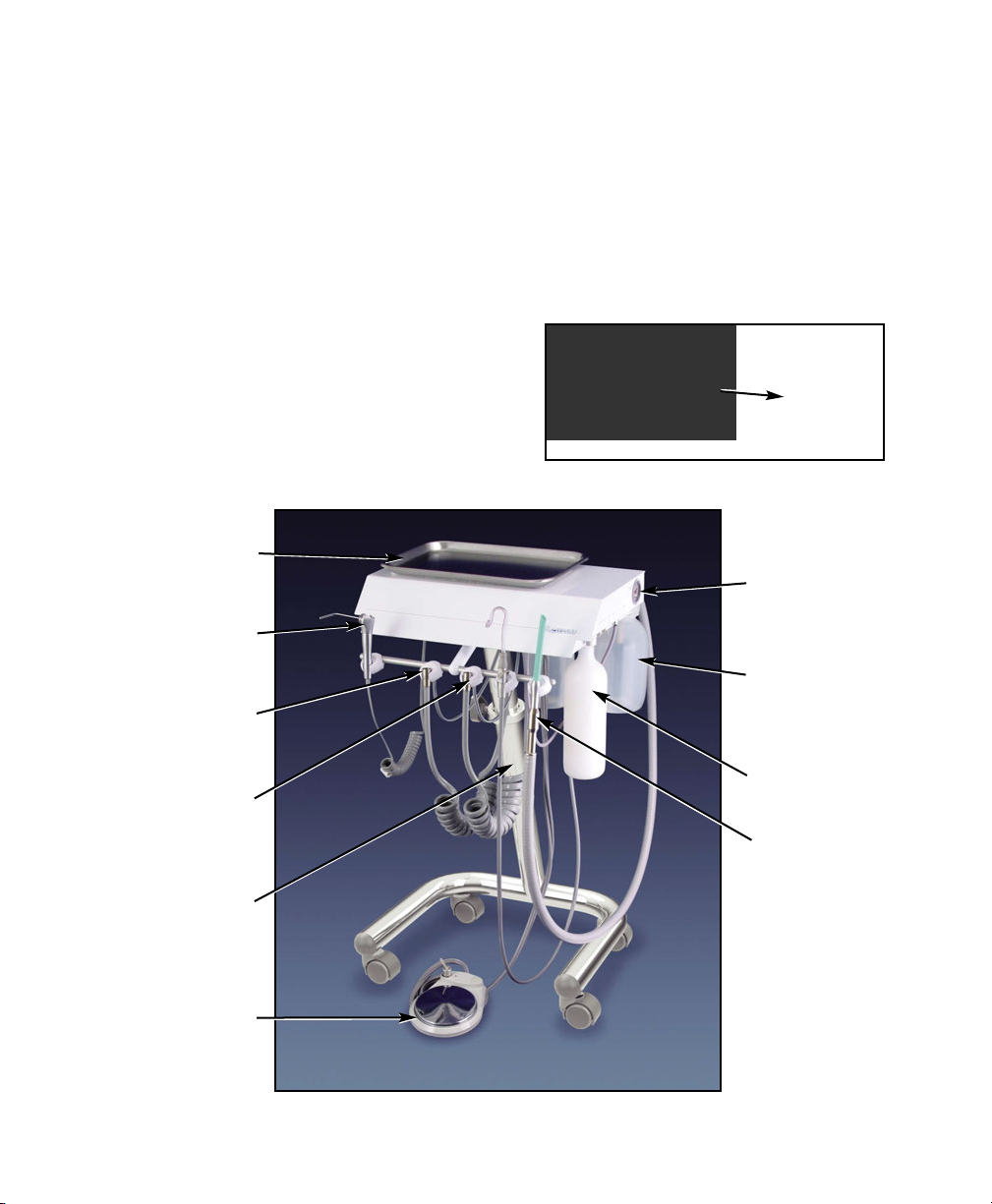

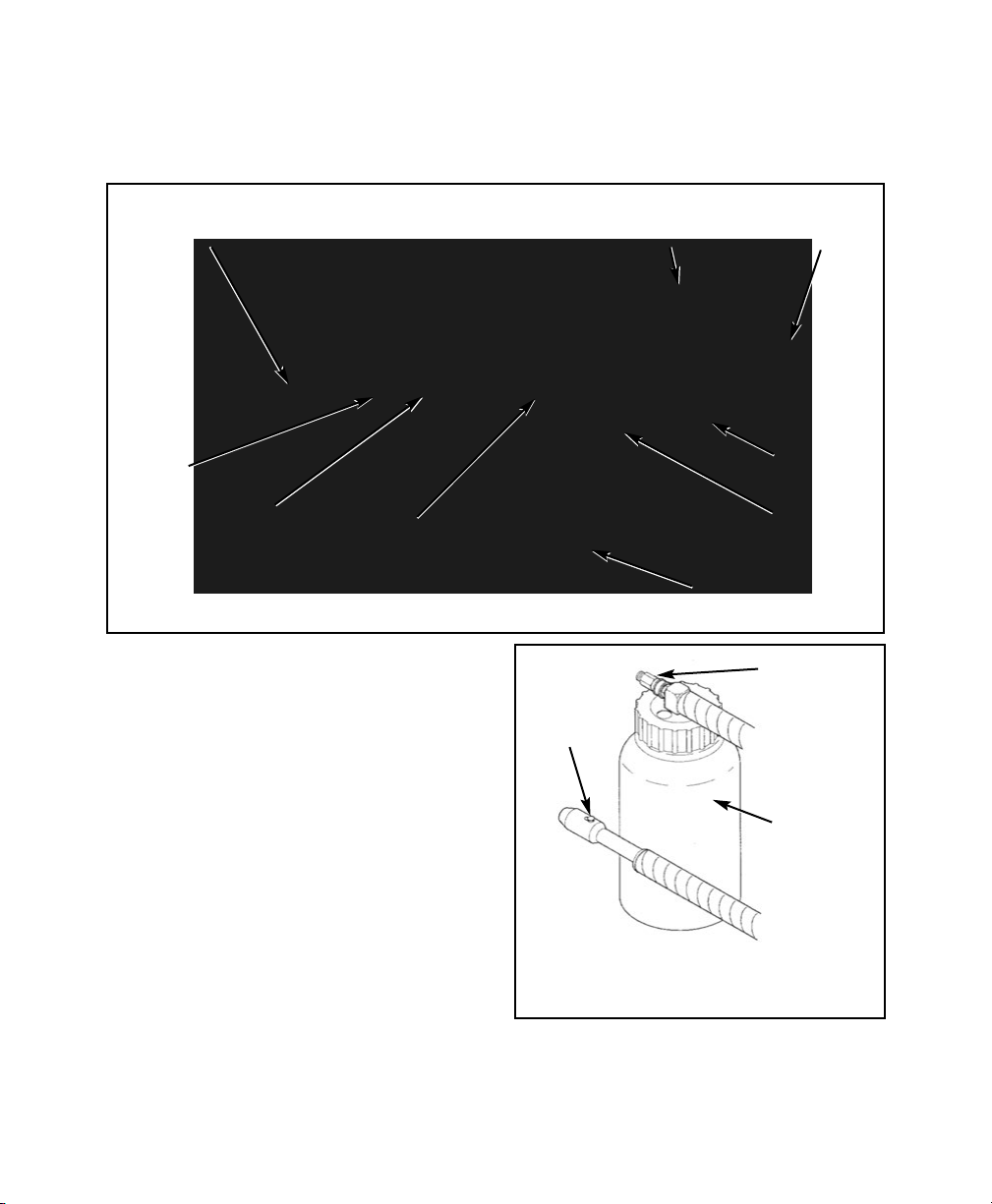

4. WATER SU LY TANK (Optional) - The

Aseptico ADU-25 may incorporate a self

contained pressurized water system (Fig.

9). This consists of a 1-liter HDPE tank

dispensing water through the 3-way syringe

and handpiece control. The water tank is

pressurized to a constant 35 pounds per

square-inch gauge (PSIG) during use.

Before removing the tank for refilling, it

must be depressurized by turning the tank

1/4 turn counterclockwise. The tank is

removed by unscrewing it from its mount

at the bottom right rear of the chassis.

After the tank is filled, screw it back onto

the mount. Cleaning and sanitization of

the tank is recommended between uses.

5. RESSURE GAUGE (Fig. 10) - The

pressure gauge on the right panel gives

you a visual indication of the handpiece

drive pressure.

6. WATER COOLANT FLOW CONTROL

(Fig. 10) - Adjusts the flow of water coolant

to the handpiece control.

7. FLUSH TOGGLE (Fig. 10) - The flush

toggle located on the right side of the

chassis allows you to quickly and

completely flush your handpieces, washing

away contaminants which may have

accumulated in the handpiece and tubing.

You should flush the handpieces for about

5 seconds after every patient, and about

20 seconds at the beginning of each day

to reduce overnight bacterial accumulation

which may have occurred.

To flush your handpieces, remove them

from their holder, directing the spray away

from you and into a basin, then flip the

flush toggle and hold the desired number

of seconds. Release the flush toggle.

8. AA-21 HIGH VOLUME VACUUM

SYSTEM (Optional) - The AA-21 Steri-Vac

is an air powered, self contained oral

evacuator system. It is supplied with a

plastic waste container and a single high

velocity hose. (Fig. 11)

Remove the vacuum bottle and hose

assembly from packing and install into the

quick disconnect at the back of the

delivery head.

To operate, remove the vacuum hose from

holder and insert a standard oral evacuator

tip. Depress the on/off switch on the side

of the hose end for vacuum.

TU N WATE SUPPLY

TANK 1/4 TU N

COUNTE CLOCKWISE

TO ELEASE

P ESSU E BEFO E

UNSC EWING

Figure 9 - Removal of Optional ater Tank