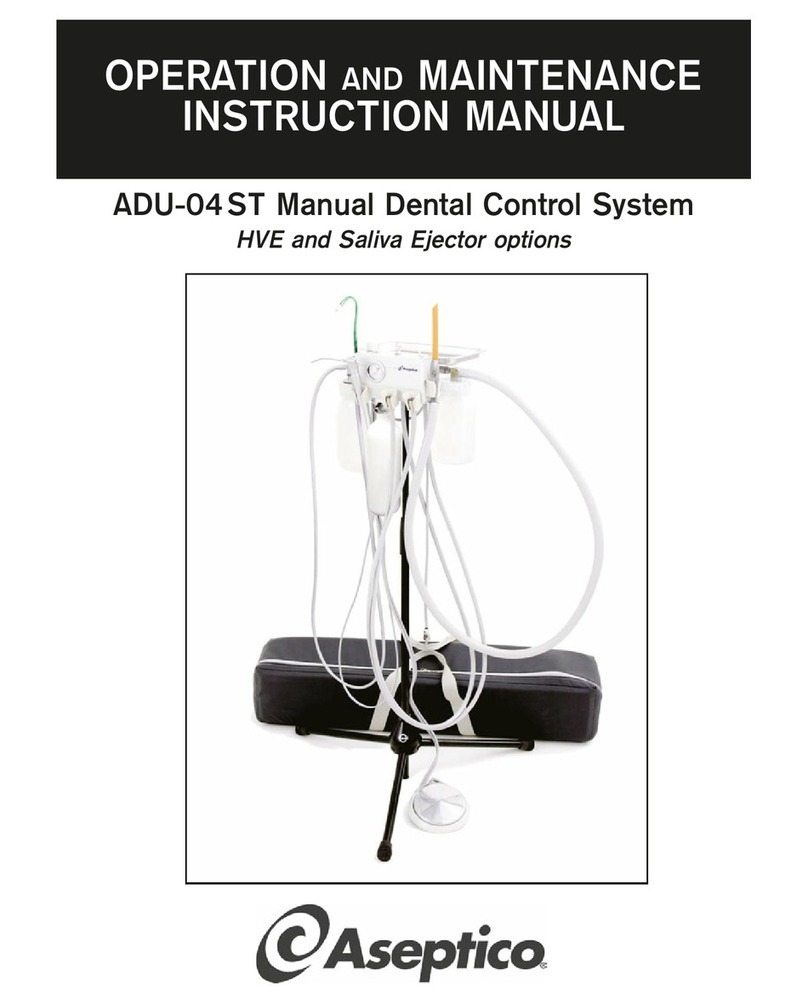

instrument holders are air-activated holders. If the High

Vacuum Evacuator (HVE) or low-volume saliva ejector

instruments (Fig. 3)

are removed from

their holders or if

they aren't properly

seated in their

holders, the com-

pressor will run

continuously, even

when the system

pressure is fully

pressurized. If the

HVE and saliva ejector instruments are seated in their

holders properly but the compressor fails to turn off, turn the

unit's power switch OFF and check for air leaks in the

system. If the system pressure gauge is showing pressure,

the leaking sound should be detectable. Use your ear, or

place a tube to your ear like a stethoscope, to locate the

source of the leak. If a leak can't be heard from any air lines

or fittings, check the air and water bottles for tightness and

the condition of their seals, and check the three O-rings from

the junction block.

Air/Water Syringe

Check the 3-Way Air/Water Syringe (Fig. 4a) by depressing

the air and water syringe buttons individually then both

simultaneously for

air/water mist. This

mist can be

adjusted with the

two syringe flow

control knobs

located on the

manifold control

panel (see Fig. 4b).

The top knob adjusts the water flow and the bottom knob

adusts the air flow. Turn the knobs clockwise to decrease the

flow or counterclockwise to increase the flow.

Water Filter

Inspect the water filter (Fig. 5) on the

end of the water pick-up tube that

protrudes into the water supply bottle.

If the filter becomes clogged and

restricts the water flow, it needs to be

cleaned by reverse flushing, or

replaced. CAUTION: Do not run saline solutions through the

water system -- saline will rust the water filter.

Air Filters

The system

provides a dual

air filtration

system. The

primary filter

(Fig. 5a) is

installed into the

door frame on

the case lid and

is used in dusty

environments. It

uses a foam filter that can be detached and cleaned. Simply

pull the foam pad off the frame studs and clean with soap

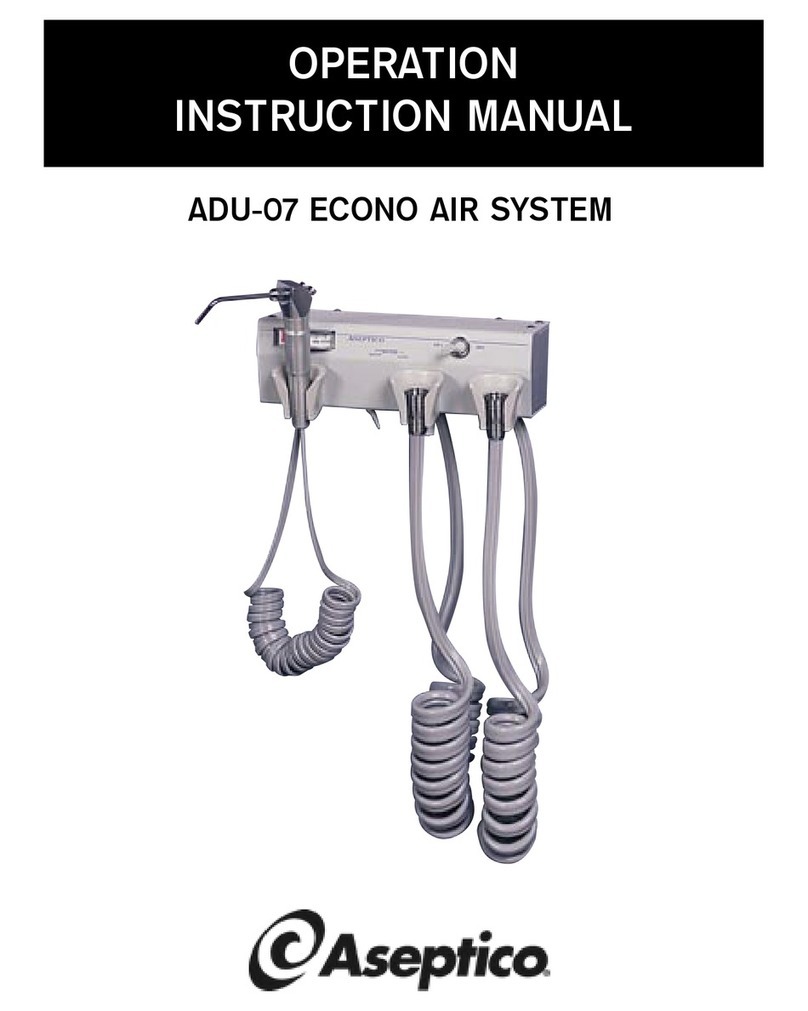

GENERAL SERVICE INFORMATION

This service manual offers information not available in the

AEU-525CF/AEU-525CFH/AEU-525CFH-14 Transport III

Operation and Maintenance Instruction Manual. It will help

you better understand the operation of the Transport III

system, thereby reducing service time. A Replacement Parts

List is also included on page 27. See the Schematic Drawing

Set (PN 420991) for assembly drawings with individual part

numbers, plumbing diagrams, and electrical schematics.

The plumbing and electrical diagrams show all air, water,

and wiring components as installed in the unit.

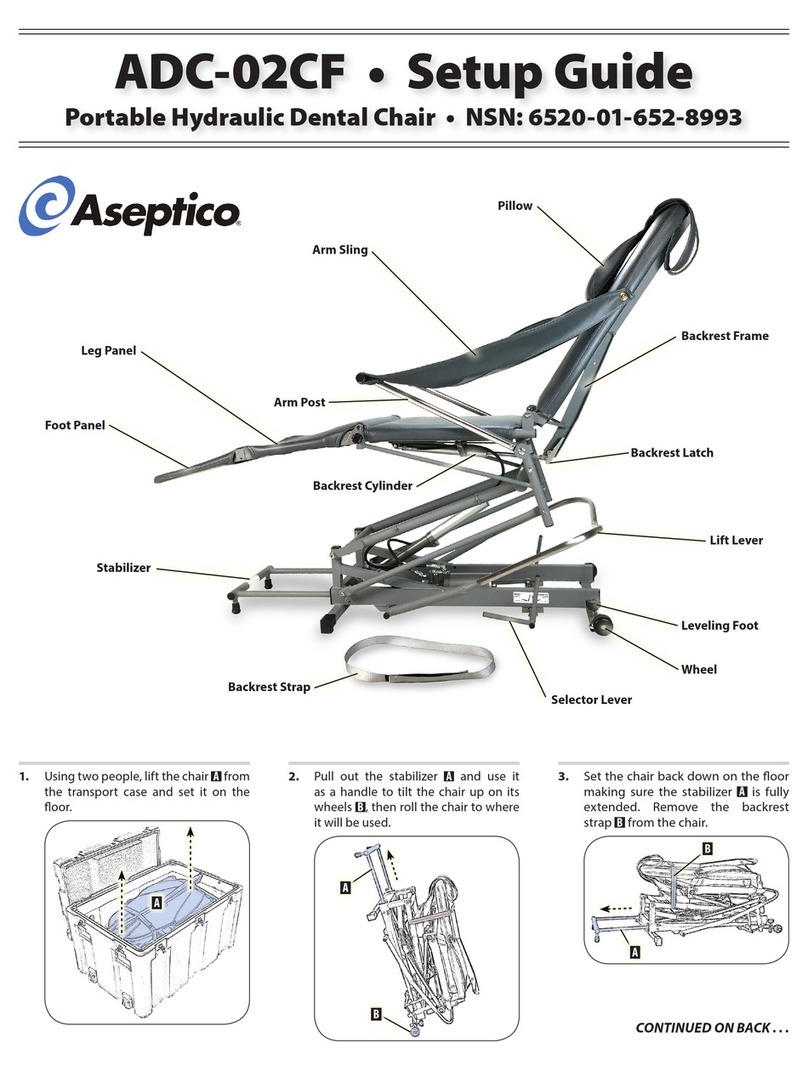

INSPECTION & OPERATION VERIFICATION

To verify that the Transport III unit is functioning properly, first

follow the Setup procedure

in the Operation and

Maintenance Manual or in

the 525 Setup Video

presented on the Aseptico

website. The System is

designed to operate from

110V or 230V 50/60Hz

power. A manually operated

switch located next to the

power inlet cord, allows the user to select the proper voltage

(Fig. 1).

Turn both rocker switches on the motor housing to the ‘ON’

position. The left-hand switch turns the unit power On/Off.

The right-hand switch acts as a circuit breaker for the

compressor. Electrical overloads will trip both switches.

Simply turn the switches back On to reset. Green LED’s

adjacent to each switch illuminate when the switches are

On. NOTE: When the unit is in use, it’s compressor motor

will occasionally turn On and Off, to maintain proper

pressure. IMPORTANT: The switch should be left in the On

position when not in use.

Toggle the water-bottle purge

switch located on the back side of

the air/ electric module to the

“PRESSURE” position (Fig. 2a).

Turn the main power switch, to

the ON position. The compressor

pump should pressurize the air

and water bottles and maintain

the system operating pressure at

45-55 PSI (3.10-3.78 bar). Check

the pressure on the gauge

located on the side of the

air/electric module (Fig. 2b).

The Transport III System uses a single compressor motor

with a split head. The split head provides pressure on one

side and vacuum on the other. The vacuum side uses venturi

boosters to increase the vacuum. The system pressure is

regulated by a switch located on the right wall of the motor

housing assembly. This switch activates the compressor

when the pressure drops to approximately 45 PSI, and it

stops the compressor when the pressure builds to

approximately 50 PSI.

The electric motor/handpiece, scaler, and vacuum

1

VOLTAGE SELECTOR

SWITCH

POWER

ON/OFF COMPRESSOR

CIRCUIT

BREAKER

Figure 1

Figure 2a

Figure 2b

WATER BOTTLE

PURGE SWITCH

PRESSURE

GAUGE

HVE

ELECTRIC

HANDPIECE

SCALER SALIVA

EJECTOR

SYRINGE

Figure 3

Figure 4a Figure 4b

SYRINGE

AIR

ADJUST

AIR

WATER

SYRINGE

WATER

ADJUST

Figure 5

Filter

DETACHABLE

AIR FILTER

Figure 5a Figure 5b

COMPRESSOR

AIR FILTER