Assa Abloy Sargent 8200 Series User manual

Other Assa Abloy Door Lock manuals

Assa Abloy

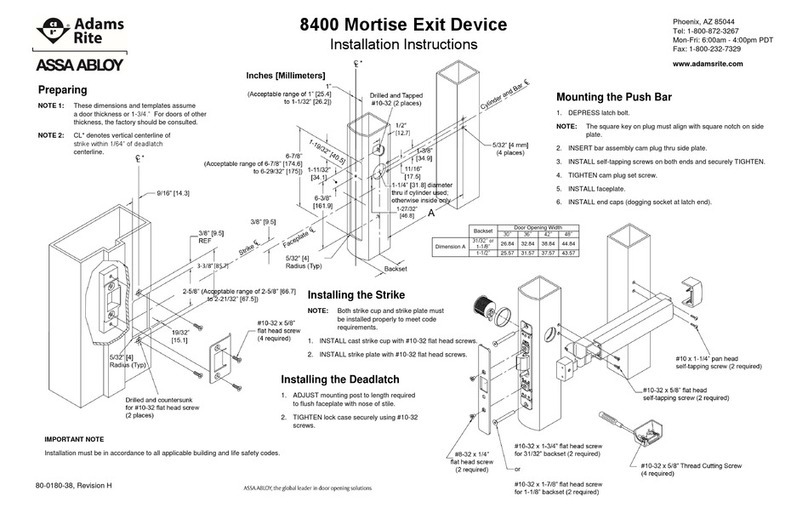

Assa Abloy 8400 User manual

Assa Abloy

Assa Abloy Yale YDM3109A User manual

Assa Abloy

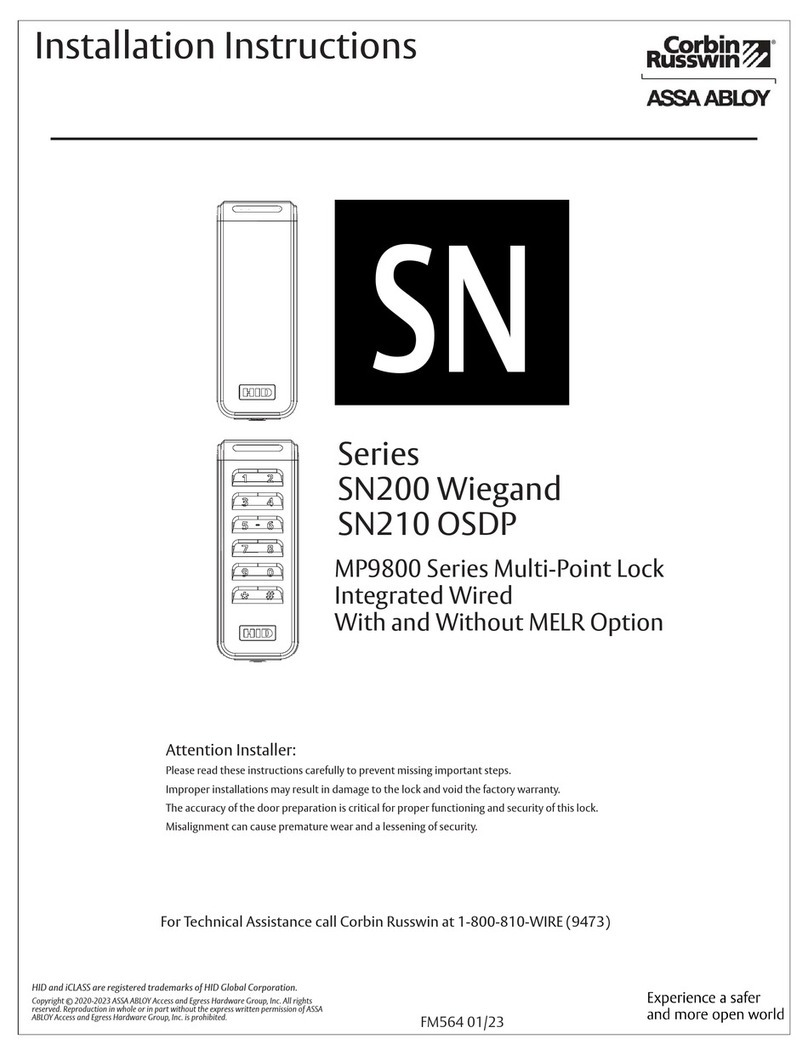

Assa Abloy Corbin Russwin MP9800 Series User manual

Assa Abloy

Assa Abloy Lockwood Cavity Lock User manual

Assa Abloy

Assa Abloy Sargent AD-PE8600 User manual

Assa Abloy

Assa Abloy Access 3 User manual

Assa Abloy

Assa Abloy ESA500 Installation manual

Assa Abloy

Assa Abloy multi-t-lock Code Handle Window User manual

Assa Abloy

Assa Abloy Corbin Russwin TL3700 Series User manual

Assa Abloy

Assa Abloy Yale Conexis L1 User manual

Assa Abloy

Assa Abloy Harmony H1 User manual

Assa Abloy

Assa Abloy 332 E91 Series User manual

Assa Abloy

Assa Abloy SARGENT7800 Series User manual

Assa Abloy

Assa Abloy Yale YDME 50 NxT User manual

Assa Abloy

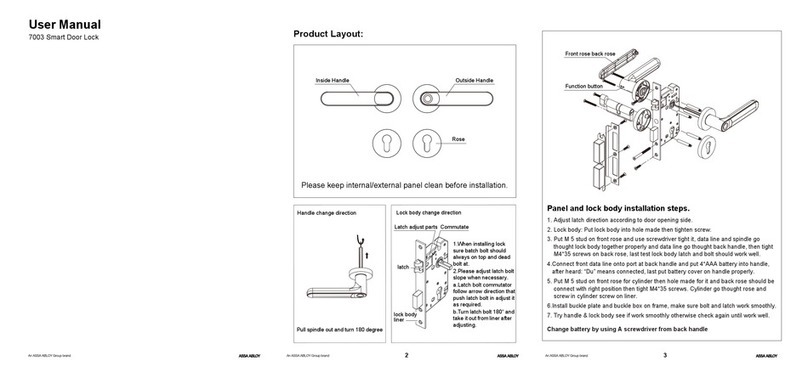

Assa Abloy 7003 User manual

Assa Abloy

Assa Abloy 179E User guide

Assa Abloy

Assa Abloy UNILOCK LOXURY IX User manual

Assa Abloy

Assa Abloy Lockwood CAVITY LOCK User manual

Assa Abloy

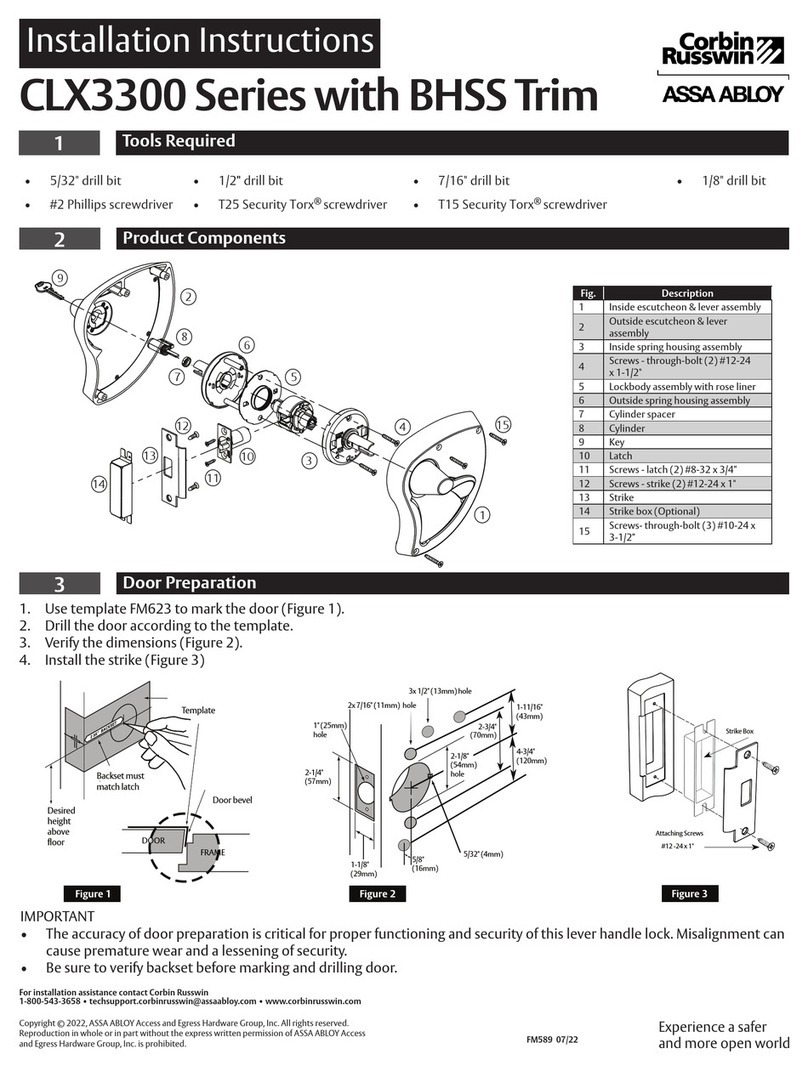

Assa Abloy Corbin Russwin CLX3300 Series User manual

Assa Abloy

Assa Abloy Yale Luna Pro User manual

Popular Door Lock manuals by other brands

SCOOP

SCOOP Pullbloc 4.1 FS Panik Assembly instruction

Yale

Yale MORTISE 8800 SERIES installation instructions

Siegenia

Siegenia KFV AS3500 Assembly instructions

Saflok

Saflok Quantum ädesē RFID installation instructions

ArrowVision

ArrowVision Shepherd 210 installation manual

Baldwin

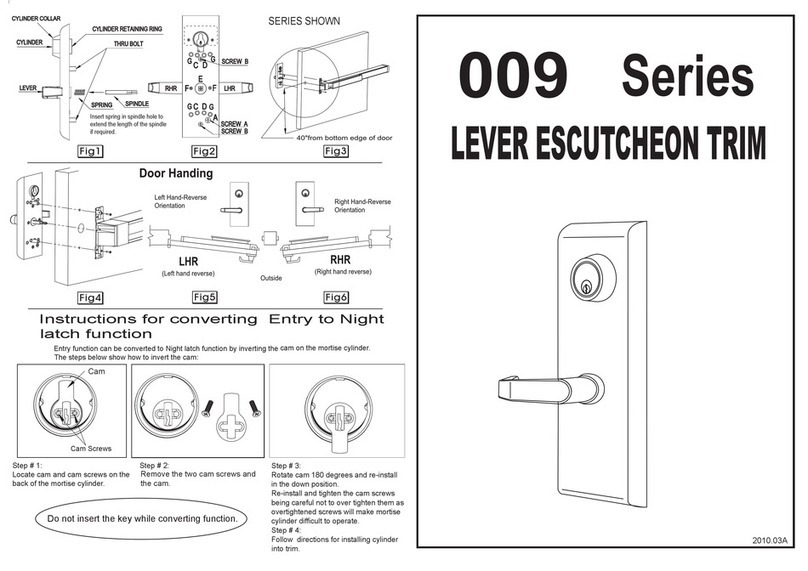

Baldwin 009 Series quick start guide