Instructions for Installing

6500 Bored Locks

(See reversed Side for Installing 6500 Series Dummy Trim)

FOR INSTALLATION ASSISTANCE CALL SARGENT AT 1-800-727-5477 / www.sargentlock.com

Copyright © 2012, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.A6913:E

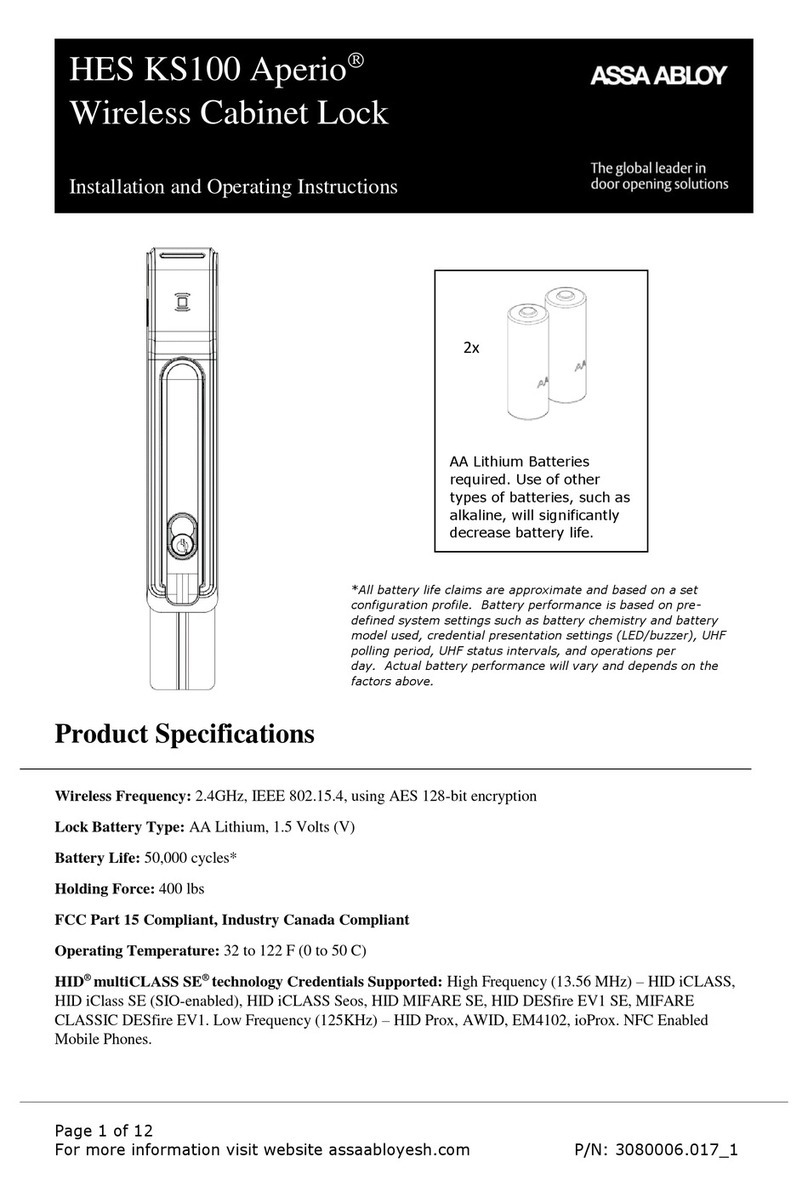

1. Place paper template (supplied) on door

and mark for holes. Repeat for other side

of door. (Follow instructions on paper

template).

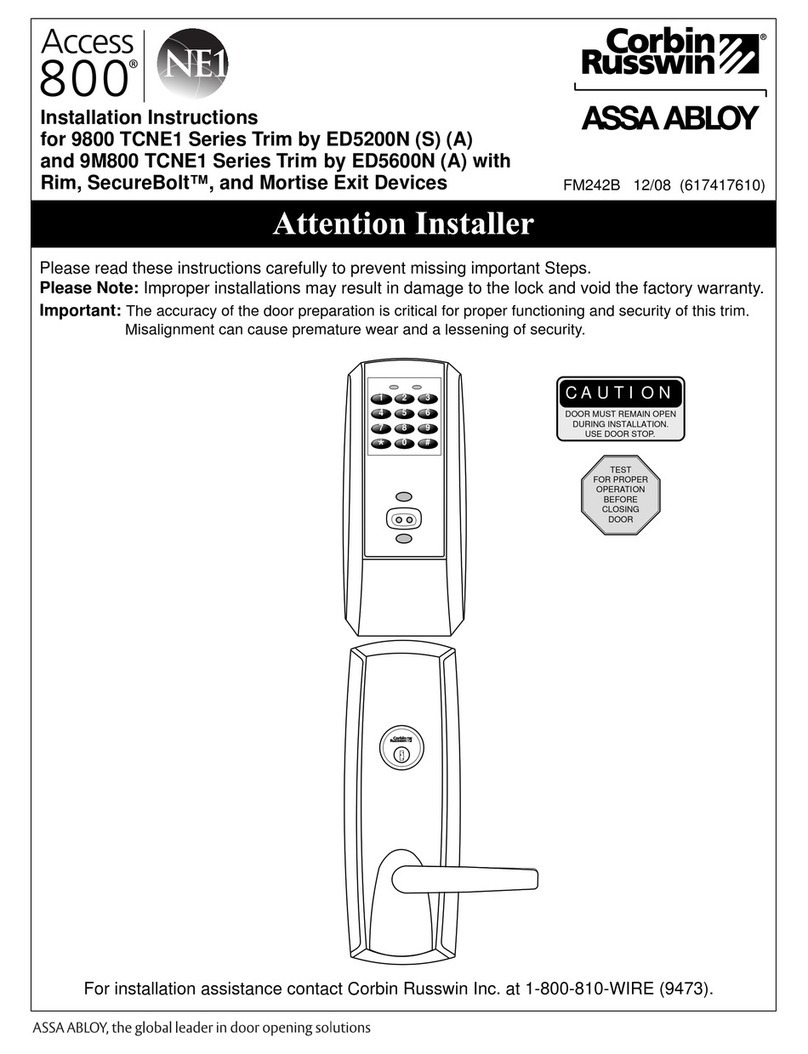

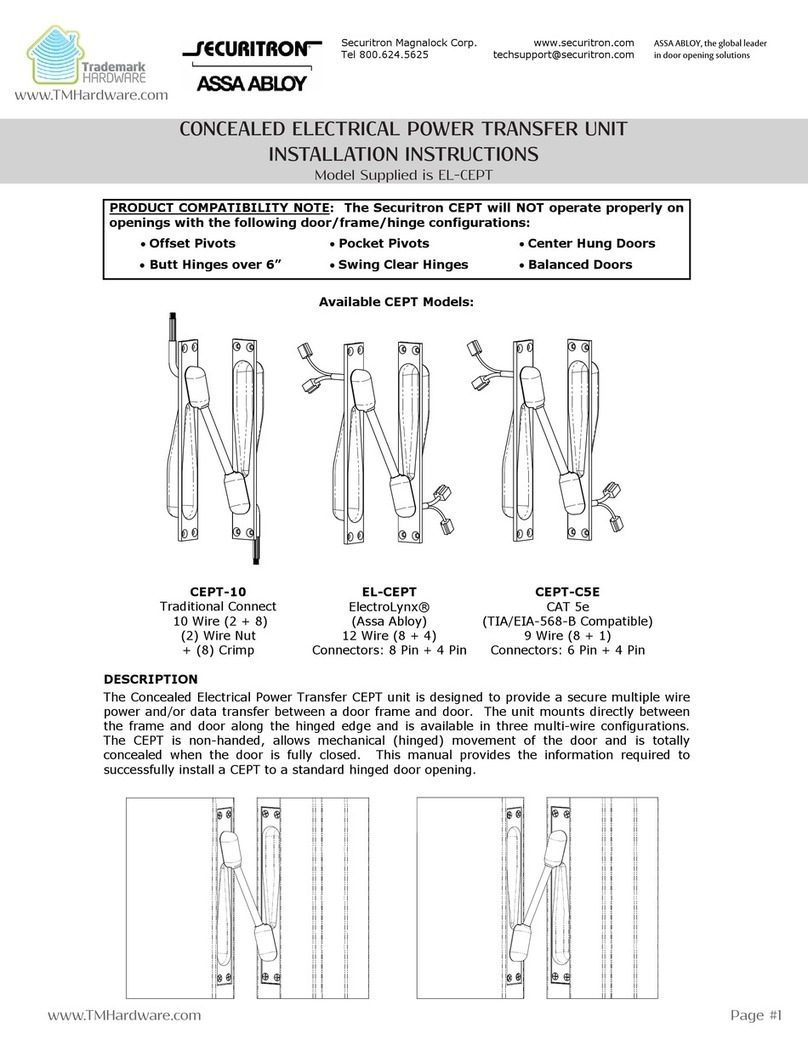

Figure 1

Figure 5

Figure 8

Figure 9

Figure 10

Figure 7

Figure 2

Figure 3

Figure 4

1. Position Lockbody (4) (as shown in g. 5) with

retractor facing the Latch Assembly (1), and the

tabs of the Adjustment Plate (6) lined up with the

notches on the door.

2. Slide the Lockbody (4) into the cross-bore hole from

the outside position.

3. Lockbody (4) must engage the

prongs of the Latch Assy. (1) as

shown.

4. The retractor of the Lockbody (4)

must engage the tailpiece of the

latch Assy. (1). Be sure the door is

open when installing lockset unit

if a guarded-latch unit is used.

5. Now you can tightly secure the

Latch Assy. (1) with Screws

(3) supplied.

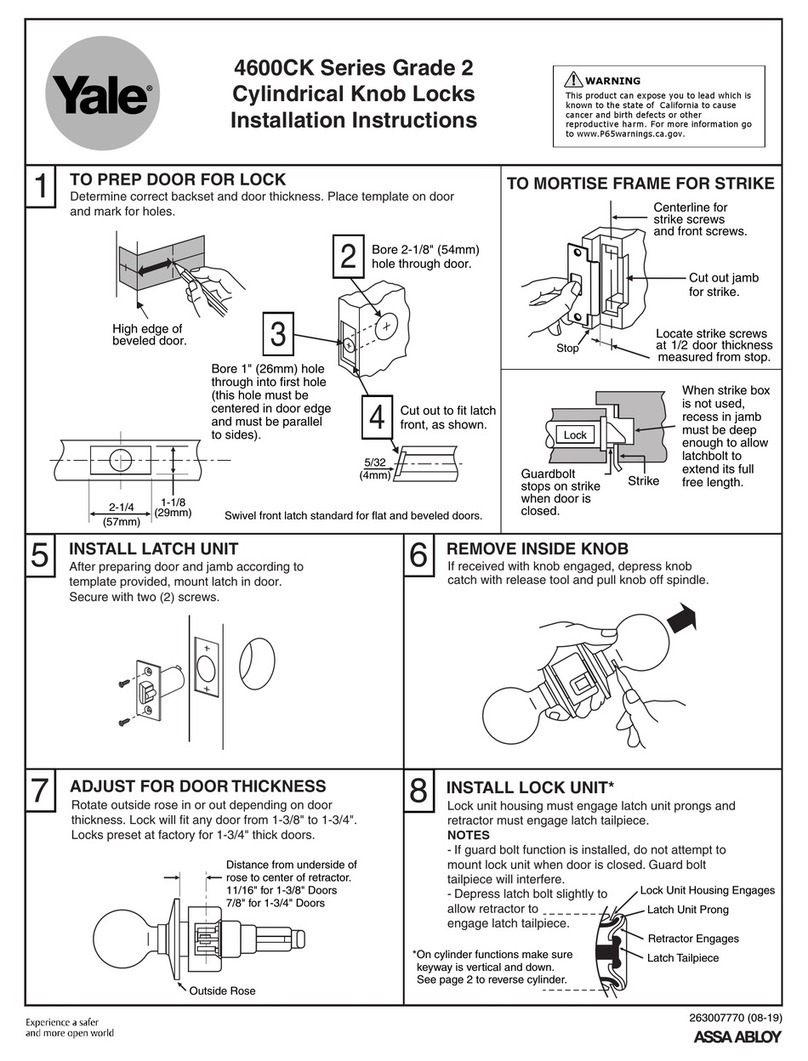

1. When Strike Box (19) is not used

(optional), recess in door jamb must be

deep enough to allow latch bolt to extend

to its full free length.

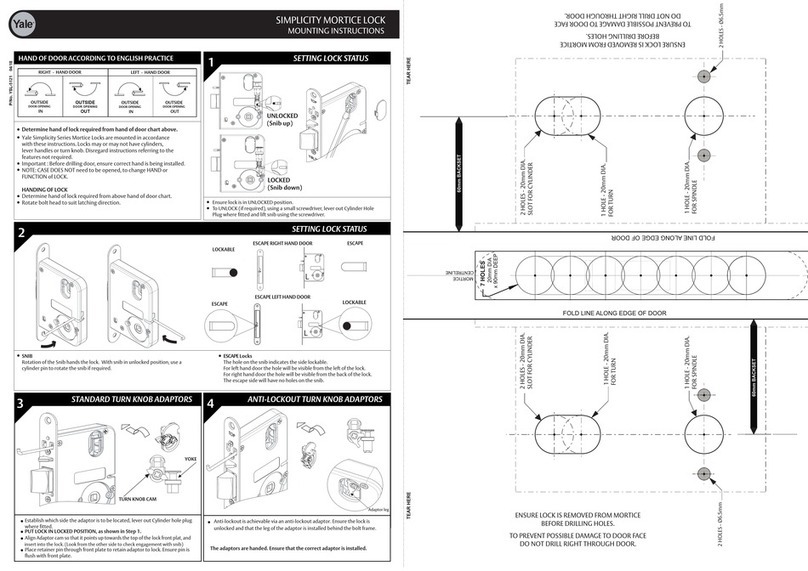

1. To remove Outside Lever (14), insert Key (16)

and turn approx. 90 ° clockwise. Insert Push

Pin (21) into the hole on lever to depress lever

catch. Slide the Lever from the Tube (5).

2. Using standard pliers, pull out the retainer (15).

3. Remove Key (16), Cylinder (13), and Cylinder

Spacer (22) from the Lever.

4. When replacing Cylinder (13), secure by

pressing Retainer (15) till ush with shelf.

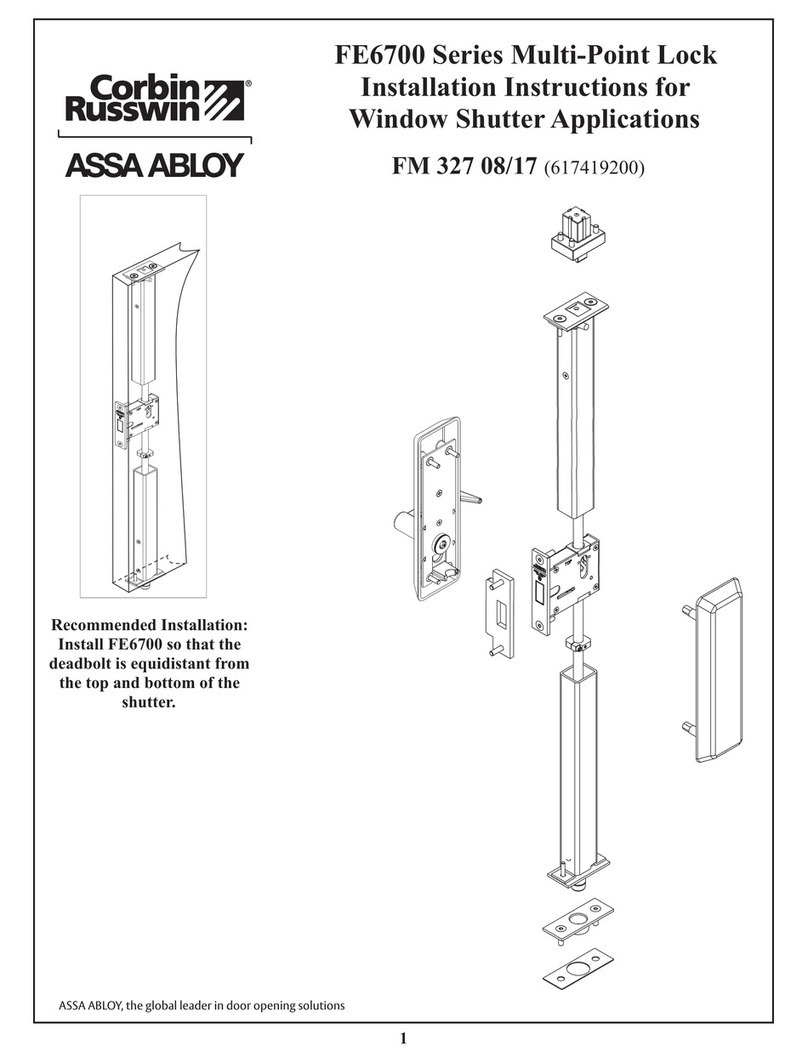

A. Door Preparation

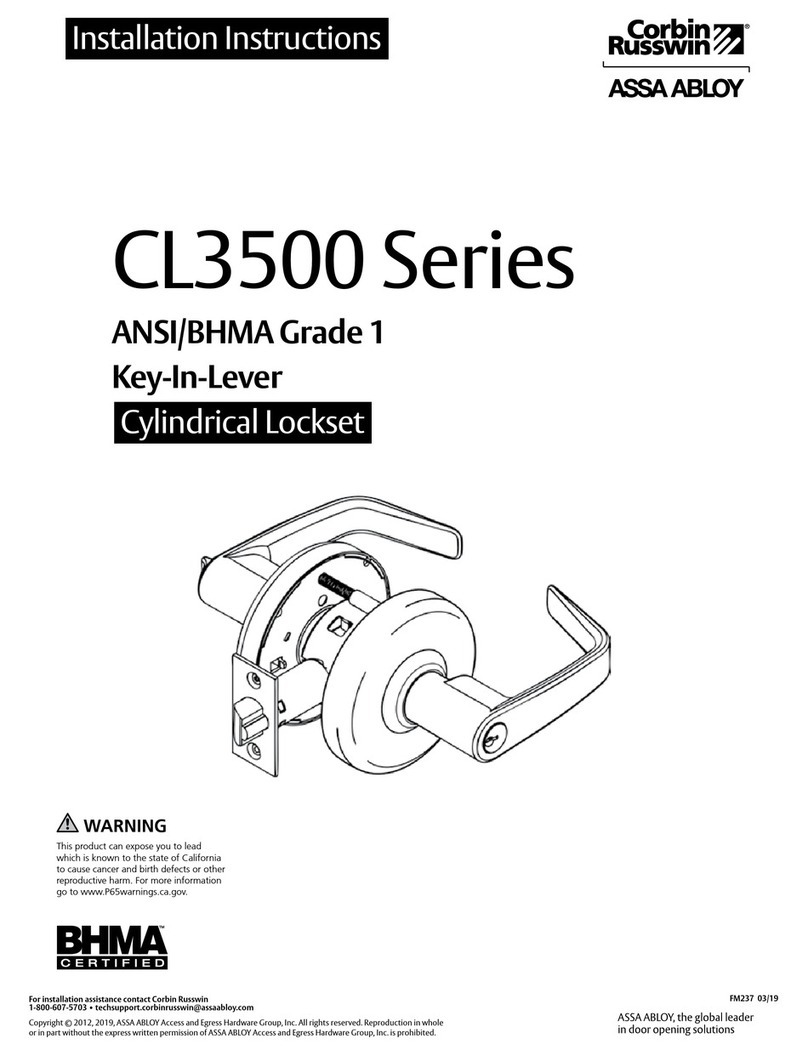

D. Installation of lockset unit

F. Installation of levers G. Installing Strike Cylinder Removal

E. Securing the lockset unit to the door

B. Latch Installation C. Adjustment for door

thickness

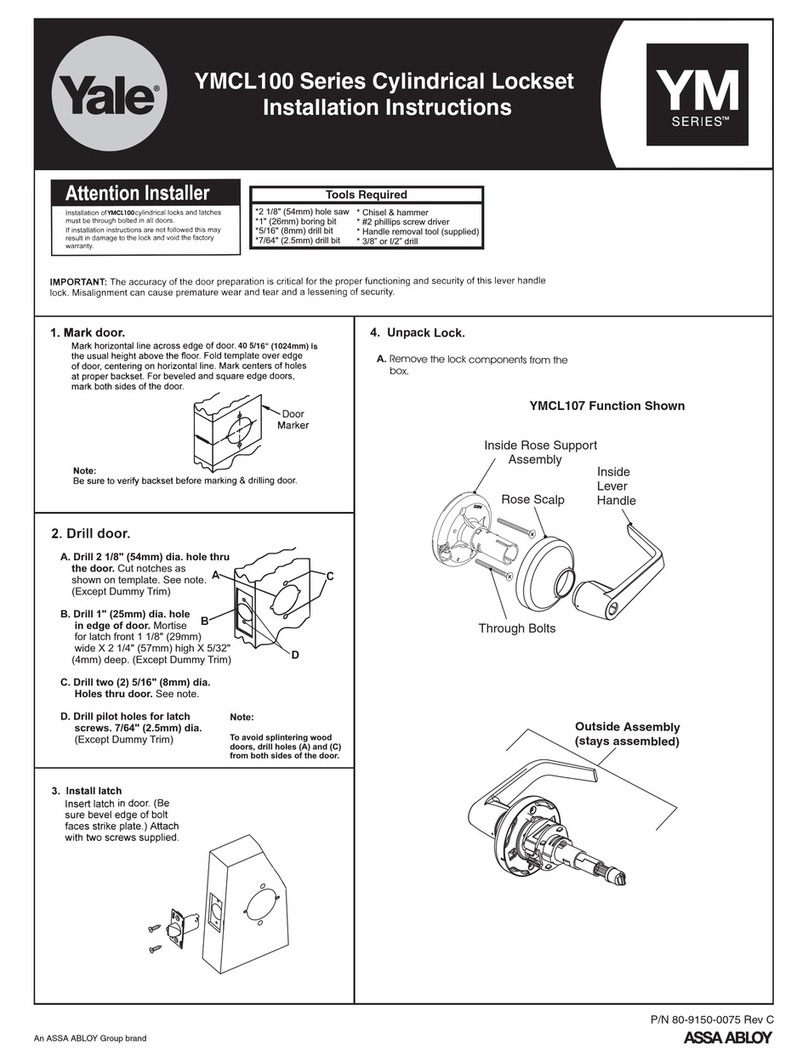

2. Drill the 2-1/8" cross-bore & put in notches.

Then, drill the 1" hole.

2A. Drill 9/64" pilot holes halfway through door

(Repeat for other side of door). Then, using

pilot holes, drill (2) 7/16" dia. holes halfway

through the door. (Repeat for other side

of door. )

3. Mortise latch unit from 5/32" into door edge

to dimensions shown.

Before inserting Lockbody (4) into the door,

adjust for door thickness.

1. Screw the Adjustment Plate (6) onto the

Lockbody (4).

3. Rotate the Plate until the required gap is

obtained.

3/16" gap for 1-3/8" door

5/16" gap for 1-3/4" door

Lock will t in any door from

1-3/8" to 1-3/4" thickness

Determine correct backset and door thickness ---

then place template on door and mark for holes

High edge of

beveled door

3. Bore 2-1/8"

hole through

door

4. Cut out to t lock

front, as shown

Cut out jamb for strike

Locate strike screws at ½ the

door thickness measured from

stop.

When strike box is not used-

recess in jamb must be deep

enough to allow latch bolt to

extend its full free length.

Guard bolt stops on strike when door is closed.

To Mortise Door for Lock

To Mortise Frame for Strike

See reverse side.

2. Bore 1" hole thru

into rst hole:

(this hole must be

centered in door

edge and must

be parallel to

sides)

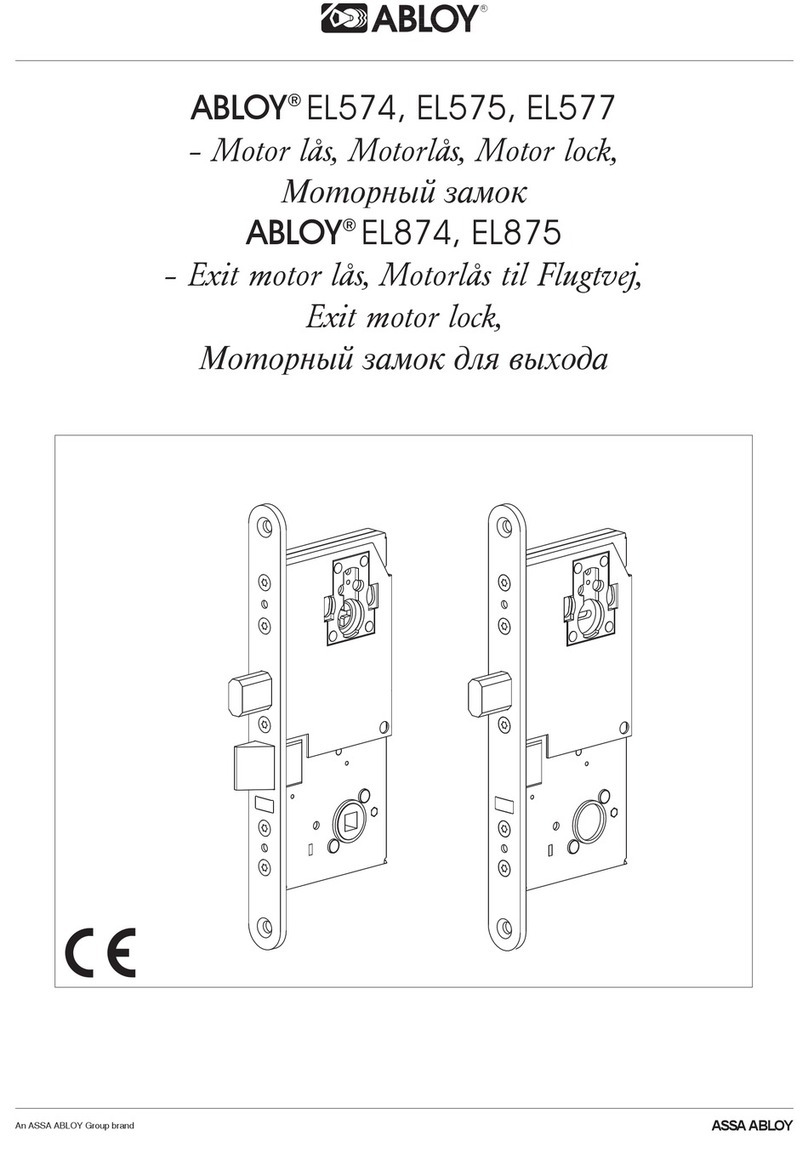

5. Slip the Scalp (12) onto the Inside Rose Assembly

(10) aligning the dimples with recesses in the Rose

and turn clockwise to lock.

1. Slide the Inside Support Plate (7) onto the Lock-

body with the tabs tting into the door notches.

2. Secure with 2 Support Plate Screws

(8) which t into the Lockbody.

3. Slide the Outside Rose Assembly (9) onto the

outside Tube (5B) with the Screw Posts entering

the post holes.

4. Slide the Inside Rose Assembly (10) onto

the Inside Tube (5A). Line up the Inside Rose

Assembly holes with the Outside Rose Assembly

Screw Posts and secure with the 2 Rose

Assembly Screws (11).

15

RETAINER

15

RETAINER

22

CYLINDER

SPACER

9

OUTSIDE

ROSE

ASSEMBLY

2

LATCH SLEEVE

(21/4" BACKSET .ONLY)

1

LATCH ASSEMBLY

3

LATCH SCREW

(2 REQ'D)

19

STRIKE

BOX

(OPTIONAL)

INSIDE

OUTSIDE

18

STRIKE

TEMPLATE

CROSS BORE HOLE

(2 1/8")

OUTSIDE

FACE

2 15/32"

MIN

7/16" DIA HOLE

(2 REQ'D)

SEE NOTE 2A.

2 9/16"

REF

2 1/4"

5/32"

NOTCH

5/32" DEEP

1" HOLE

INSIDE FACE

HOLE

1"

20

STRIKE SCREW

(2 REQ'D)

10

INSIDE ROSE

ASSEMBLY

17

INSIDE

LEVER 12

SCALP

11

ROSE

ASSEMBLY

SCREW

(2 REQ'D)

13

CYLINDER

14

OUTSIDE

LEVER

16

KEY

21

PUSH PIN

8

SUPPORT PLATE

SCREW (2 REQ'D)

7

INSIDE

SUPPORT PLATE

6

ADJUSTMENT

PLATE

5a

INSIDE

TUBE

5b

OUTSIDE

TUBE

4

LOCK

BODY

1.

LATCH

ASSEMBLY

LATCH

BOLT

BEVEL

POST HOLE

2 PLACES

TAB

(2)

5A

7

8

10

11

12

RECESS FOR

SCALP LOCKING

DIMPLE SCREW POST

(2 PLACES)

4.

LOCK BODY

GAP 8.

ADJUSTMENT

PLATE

4.

LOCKBODY

CROSS BORE HOLE

LOCKBODY

RETRACTOR

RETRACTOR

OUTSIDE FACE

PRONGS

TAB

TAB

NOTCH

1.

LATCH ASSEMBLY

1.

LATCH

ASSEMBLY

VIEW FOR

FIG. 6

17 5B

22

15

5A

15

13

14

16 20

SCREW

18

STRIKE

19

STRIKE BOX

(OPTIONAL)

14

OUTSIDE

LEVER

13

CYLINDER

15

RETAINER

22

CYLINDER SPACER

16

KEY

SHELF

LATCH ASSEMBLY

TAIL PIECE

8.

ADJUSTMENT

PLATE

Figure 6

LEVER CATCH

LEVER

CATCH

1. If backset is 2-3/4", slide latch sleeve

(2) onto the latch assy. (1).

(as shown).

2. Insert Latch Assy. (1) into 1" hole,

making certain that latch bolt bevel

faces direction of closing door.

(as shown)

3. DO NOT secure Latch Assy. (1)

until engaged with Lockbody (4),

as described in Figure 6.

2.

LATCH SLEEVE

(2 3/4" BACKSET .ONLY)

5B

10

1. Slide Cylinder Spacer (22) onto the

Cylinder (13). Open end of the Spacer

ts over the Cylinder Barrel. (See Figure 8).

2. Insert the Cylinder (13) into the Outside

Lever (14) and secure with Retainer (15).

3. Slip the Outside Lever (14) onto the

Outside Tube (5B) as far as possible.

Insert the Key (16) and turn approx. 90°

clockwise. Push the lever again until

the lever catch is engaged, securing

the lever. (Lever Catch my need to be

depressed, using Push Pin (21).)

4. Insert the remaining Retainer (15) into

the Inside Lever (17) and slide the Lever

onto the Inside Tube (5A). Push the lever

until the lever catch is engaged. (Lever

Catch may need to be depressed using

push pin (21).

4.

LOCKBODY