auto maskin Marine Pro DCU 410E User manual

Manual# 1006422

User’s Manual

DCU 410E –Engine Control Unit

RP 410E –Remote Panel

RP 410E

DCU 410E

User’s Manual – 400E Series

Page ii

User's Manual

for

Marine Pro 400E Series

~~~

DCU 410E –Engine Control Unit

RP 410E –Remote Panel

Revision

1.1

Revised

September 20, 2016

Revision history:

Rev.

Date

Description

1.0

16.11.2015

Initial Release Revision.

1.1

20.09.2016

Updates for RP 410E

Copyright © 2016 by Auto-Maskin AS.

All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Auto-Maskin AS.

User’s Manual – 400E Series

Page iii

Table of Content

DOCUMENT INFORMATION ................................ 1

ABOUT THIS MANUAL.............................................. 1

Responsibilities .............................................. 1

ORDERING INFORMATION......................................... 1

Copyrights and Trademarks .......................... 1

Contact Information ...................................... 1

OVERVIEW OF THE 400 SERIES .................................. 2

Available Modules ......................................... 2

DCU 410E OPERATION......................................... 4

CONFIGURATIONS ................................................... 4

BUTTONS .............................................................. 4

SCREEN LAYOUT ..................................................... 4

Status bar ...................................................... 4

Main screen area........................................... 4

Softbutton bar ............................................... 4

STATUS BAR SYMBOLS.............................................. 5

Automatic Mode............................................ 5

Emergency Mode........................................... 5

Manual Mode ................................................ 5

Harbor Mode ................................................. 5

Shutdown Override........................................ 5

Service ........................................................... 5

All OK ............................................................. 5

START ENGINE ....................................................... 6

Latched Start ................................................. 6

Hold Start ...................................................... 6

E-Start............................................................ 6

STOP ENGINE......................................................... 7

Latched Stop.................................................. 7

Hold Stop ....................................................... 7

ALARM LIST ........................................................... 8

Indication....................................................... 8

Enter the Alarm List ....................................... 8

Filter Alarms .................................................. 8

Silence the Buzzer.......................................... 8

Acknowledge a single alarm.......................... 8

Acknowledge all alarms................................. 9

Further reading.............................................. 9

SOFTBUTTONS........................................................ 9

Softbuttons in Instrument View..................... 9

MENU ................................................................ 11

Settings........................................................ 11

Log & Counters ............................................ 15

Screen Backlight .......................................... 17

Help ............................................................. 17

VERSION INFORMATION ......................................... 22

RP 410E OPERATION .......................................... 23

INTRODUCTION .................................................... 23

SCREEN LAYOUT ................................................... 23

STATUS BAR SYMBOLS............................................ 24

START ENGINE ..................................................... 24

E-Start.......................................................... 25

STOP ENGINE....................................................... 25

ALARM LIST ......................................................... 26

Enter the Alarm List ..................................... 26

Silence the Buzzer ........................................ 26

Acknowledge a single alarm........................ 26

Acknowledge all alarms............................... 26

Active Station indication in the Alarm List... 26

Filter Alarms ................................................ 26

MENU ................................................................ 28

Active Station .............................................. 28

Settings........................................................ 29

Log & Counters ............................................ 30

Camera ........................................................ 31

Backlight...................................................... 31

Help ............................................................. 31

THE ALARM LIST ................................................ 33

Severity number........................................... 33

Bold text ...................................................... 33

Background colors ....................................... 33

Sample events ............................................. 34

User’s Manual – 400E Series

Page 1

Document

Information

About this Manual

This manual has been published

primarily for professionals and

qualified personnel.

The user of this material is assumed to

have basic knowledge in marine

systems, and must be able to carry out

related electrical work.

Work on the low-voltage circuit should

only be carried out by qualified and

experienced personnel.

Installation or work on the shore

power equipment

must only

be carried

out by electricians authorized to work

with such installations.

Responsibilities

It is the

sole responsibility of the

installer

to ensure that the installation

work is carried out in a satisfactorily

manner, that it is operationally in good

order, that the approved material and

accessories are used and that the

installation meet all applicable rules

and regulations.

Note! Auto-Maskin continuously

upgrades its products and reserves the

right to make changes and

improvements without prior notice.

All information in this manual is based

upon information at the time of

printing.

For updated information, please

contact your local distributor.

Ordering information

The Marine Pro covers a wide range of

compatible products within both the

200- and 400 Series. Please visit our

web site for more information.

http://auto-maskin.com/marine/

Copyrights and

Trademarks

Copyright © Auto-Maskin AS, 2016.

Information given in this document

may change without prior notice. This

document should not be copied

without written permission from Auto-

Maskin.

All trademarks acknowledged.

Contact Information

See the website to locate the nearest

distributor.

www.auto-maskin.com

User’s Manual – 400E Series

Page 2

Overview of the 400

series

Available Modules

These are some of the main modules

available in the 400 series:

DCU 410/E Engine Control Unit

DCU 408 Engine Control Unit,

without user interface

SDU 404 Safety Unit

SDU 410 Safety Unit

RIO 410 I/O Expansion Unit

RIO 412 Exhaust Temperature

Unit

RP 410/E Remote Panel

The following is a brief explanation of

the different modules.

DCU 410E/408 Engine Control

Units

The DCU 410E and DCU 408 are

engine monitoring and control units.

One panel is required for each engine.

The DCU 410E has a color screen, and

buttons for user interaction.

The DCU 408 does not have screen or

buttons, and is intended for use with

remote panels.

Note! The DCU 410E and DCU 408 will

hereafter be referred to as the “DCU”

only. If functionality differs between

the two, this will be noted.

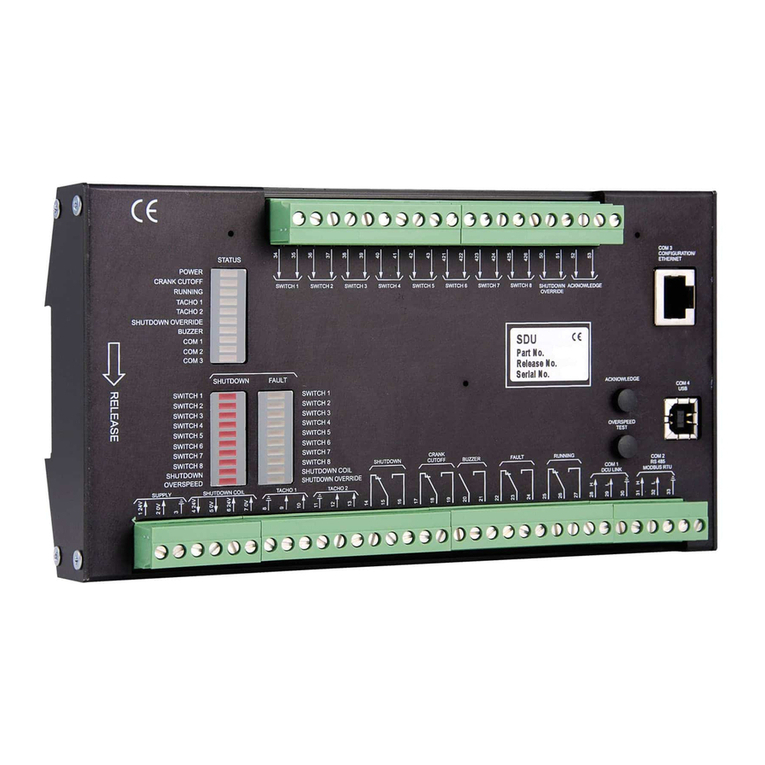

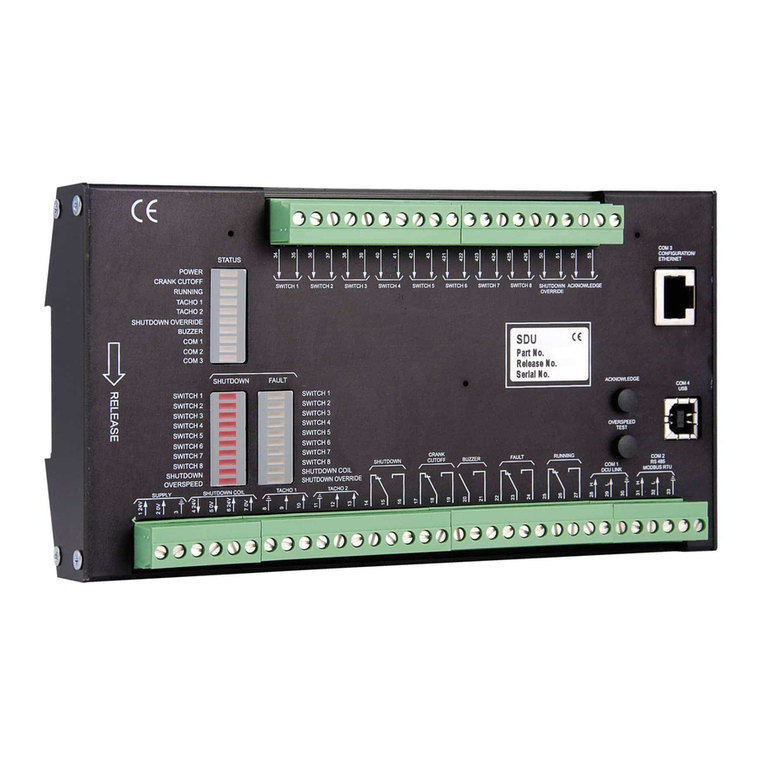

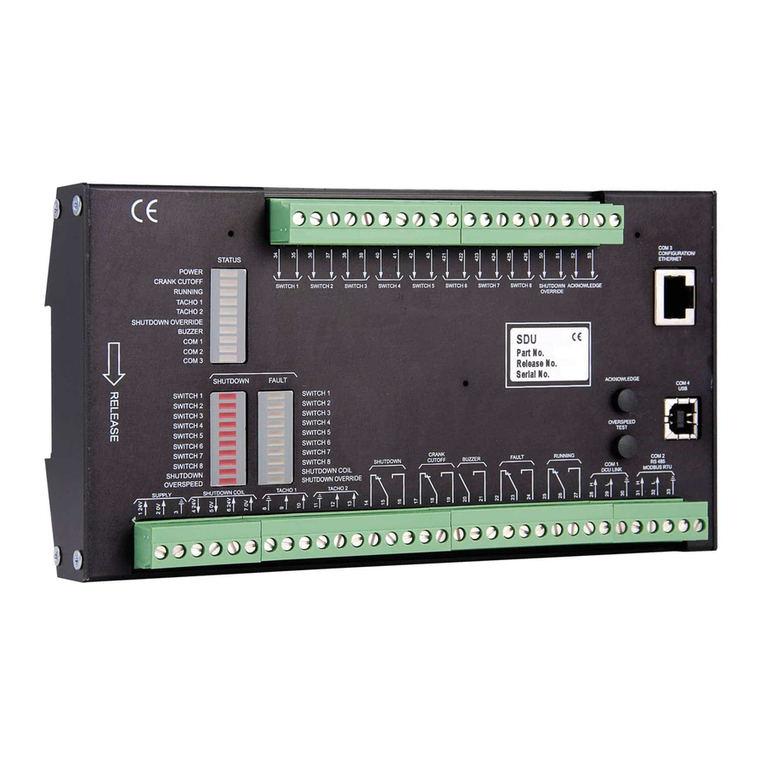

SDU 404/410 Safety Unit

The SDU 404/410 is the safety

module, and is linked to the DCU

engine control unit. It is mandatory in

classed installations that are to be

type approved.

When connected to the SDU link of a

DCU, the DCU will detect it

automatically.

RIO 410 I/O Expansion Unit

The RIO 410 is an I/O expansion unit,

and is linked to the DCU.

A maximum of four RIO units can be

connected to one DCU.

When connected to the RIO link of a

DCU, the DCU will detect it

automatically

RIO 412 Exhaust Temperature

Unit

The RIO 412 is an expansion unit with

20 thermocouple channels. The

operator can read individual cylinder

temperatures, as well as average

values.

When connected, the DCU detects it

automatically and adds a new page to

its configuration.

User’s Manual – 400E Series

Page 3

RP 410E Remote Panel

The RP 410E is the remote panel for

the DCU engine panels.

Numerous RP remote panels can be

connected together in the same

Ethernet network.

One RP 410E can be connected to a

maximum of eight DCU units.

When an RP 410E remote panel is

connected on the Ethernet link to one

or several DCU units, the RP can

update its configuration automatically.

User’s Manual – 400E Series

Page 4

DCU 410E

Operation

Configurations

The behavior of the DCU 410E

depends heavily on its configuration.

For instance, the start/stop buttons

can be configured as latched, meaning

the DCU completes the start/stop

cycle once the button is pressed, or it

can be configured as hold-to, meaning

the operator must keep the button

pressed until the engine has started or

stopped.

The configuration of the DCU is not

part of this document.

Buttons

The DCU has ten buttons for the

following:

Engine Start

Engine Stop

Display/Hide Alarm List

Display/Hide Menu

Menu navigation with arrow

up/down

Four “softbuttons”with screen-

dependent functionality

Screen Layout

The screen is divided into three main

sections from the top and downwards

as follows:

Status bar

Top-most line on the screen, which is

reserved for engine state (left) and

status symbols (right).

The status bar flashes in the event of

an alarm.

Main screen area

This is where all instruments and

menu items are displayed.

Softbutton bar

Bottom-most line on the screen, which

is reserved for softbuttons.

These have varying functionality

depending on the current screen.

Status bar

Main screen

area

Softbutton bar

User’s Manual – 400E Series

Page 5

Status bar symbols

These are the symbols in the top-right

area of the status bar.

Several symbols may be visible

simultaneously.

DCU is in automatic mode.

DCU is in emergency mode.

DCU is in manual mode.

DCU is in local mode.

DCU is in

harbor

mode.

DCU is in

shutdown override

mode.

A service interval is past due.

All OK.

(no alarms)

Automatic Mode

The DCU is ready to accept automatic

start- and stop commands.

Local start- and stop is possible.

Emergency Mode

This mode is available only if the DCU

is configured as a Combined

Harbor/Emergency set.

Channels configured as shutdown will

not give an engine shutdown, but

indicate with an alarm only.

The Exception is overspeed, which is

not disabled.

Manual Mode

The DCU does not accept automatic

start- and stop commands.

Local start and stop is possible.

Harbor Mode

This mode is available only if the DCU

is configured as a Combined

Harbor/Emergency set.

Shutdown channels are enabled.

Automatic start/stop is disabled.

Shutdown Override

All channels configured as shutdown

will give alarm only.

The exception is overspeed, which is

enabled.

Service

A service interval is past due.

All OK

There are no alarms in the alarm list.

User’s Manual – 400E Series

Page 6

Start Engine

The start button can be configured as

latched

or

hold

. It will always be the

same as the stop button, though.

Latched Start

If the button is configured as

latched

,

press the start button, observe the

confirmation dialog, and press the soft

button Start to start.

The DCU will complete the start

sequence.

Hold Start

If the start button is configured as

hold

, press and hold the start button

until the engine has started.

There will be no confirmation dialog.

E-Start

If the DCU is configured for it, an

Emergency Start option is available in

the Start dialog. See the previous

picture.

Note! Activating E-Start will override

any configured Prelube and also set

Shutdown Override. The engine will

start immediately, and run in a

Shutdown Override mode setting.

If necessary, the operator can switch

off Shutdown Override mode once the

engine has started.

User’s Manual – 400E Series

Page 7

Stop Engine

The stop button can be configured as

latched

or

hold

. It will always be the

same as the start button, though.

Latched Stop

If the button is configured as

latched

,

press the stop button, observe the

confirmation dialog, and press the

stop softbutton to start.

The DCU will complete the stop

sequence.

Hold Stop

If the stop button is configured as

hold

, press and hold the stop button

until the engine has stopped.

There will be no confirmation dialog.

User’s Manual – 400E Series

Page 8

Alarm List

Indication

Whenever there is a new event in the

alarm list, the DCU indicates as

follows:

Buzzer oscillates

Alarm list LED flashes

The screen status bar flashes

Note! The color of the flashing LED

and status bar is either yellow

(warning) or red (alarm or shutdown)

depending on the most severe

unacknowledged event in the list.

Enter the Alarm List

To see the alarm list, press the alarm

list button.

Press the button again to leave the

alarm list.

The above picture indicates a warning

in the alarm list.

Filter Alarms

The alarm list can filter alarms in three

groups

All Alarms (all alarms and

diagnostics)

Panel Alarms (all alarms, no

diagnostics)

Diagnostics (diagnostics only)

To switch between the different views,

press the corresponding softbutton 2

and/or softbutton 3.

Silence the Buzzer

If the buzzer sounds,

press the alarm list button

to silence the buzzer.

If the alarm list is

currently

not

displayed, then

this operation will display the

alarm list.

If the alarm list

is

displayed,

then pressing the alarm list

button to silence the buzzer will

not exit the alarm list.

Acknowledge a single

alarm

In the alarm list, select the

alarm to be acknowledged

using the arrow buttons. Note

that the selected alarm line will

expand to reveal additional

information, if any.

Press the Acknowledge button

to acknowledge the selected

alarm.

User’s Manual – 400E Series

Page 9

Acknowledge all alarms

In the alarm list, press and hold

(~1 sec) the Acknowledge

button. This acknowledges all

alarms.

Note that alarms that are still active

will stay displayed in the screen until

they go inactive.

Further reading

For an explanation around the use of

colors and bold text in the alarm list,

see the chapter on page 33.

Softbuttons

The DCU has four softbuttons, see

picture below.

These are located at the bottom of the

screen, and changes depending on the

actual screen.

Softbuttons in Instrument

View

There are four functions assigned to

the softbuttons in instrument view.

These four functions are also available

elsewhere in the menu.

Language

Note that there are two pages to select

from in the Language menu.

Select the desired language and press

the Ok button.

User’s Manual – 400E Series

Page 10

Backlight

Select the desired backlight intensity.

Note that if 10% is selected, the menu

will still be using 50% backlight.

Units

Select the preferred unit of measure.

Press the Ok button to select.

Mode

Select the mode of operation.

Automatic Mode

The DCU accepts external automatic

start- and stop commands, as well as

remote start- and stop commands.

Manual

The DCU does

not

accept external

start- and stop commands.

It does accept remote start- and stop

commands.

Local

The DCU does not accept

any

external

commands.

Local start- and stop commands are

accepted.

User’s Manual – 400E Series

Page 11

Menu

Press the menu button to access the

menu.

Settings

Note that the settings menu has two

pages.

Mode

Select the mode of operation. This is

discussed on page 10.

Start Disabled

Set active to disable all starts, also

local start.

Note! It is recommended to remove

the start battery connection before any

maintenance work on the engine.

Prelube Override

Set active to override prelube.

If selecting Prelube Override during a

prelube sequence, the prelube will be

cancelled and the DCU will continue to

crank the engine.

Button Beep

Set to disabled to not have the internal

buzzer beep for every button press.

Language

Select the language. All internal

messages are ready translated. All

configured signals must be translated

in the configuration.

If a signal does not have a text

description in the selected language,

then the English language will be

used.

If the signal does not have an English

text description either, then the

channel name

will be used, eg. “4-

20mA channel #1”.

Units

Select the units of operation, Metric or

U.S.

Metric (Celsius, bar, etc), or

U.S. (Fahrenheit, psi, etc)

Note that the selection is local to this

panel only.

Wallpaper

Set the wallpaper (background image)

for instruments, menus and popups

respectively.

User’s Manual – 400E Series

Page 12

Engine Overspeed Test

In this mode, the engine can be tested

for overspeed by lowering the

overspeed setpoint to 90% of the

nominal (max) speed.

Activate

Make sure the engine is not

running. The Overspeed Test

mode cannot be entered on a

running engine.

Note that the overspeed

setpoint has been lowered by

observing the red are on the

RPM meter.

Start the engine and adjust rpm

until it crosses the red labeled

setpoint.

Observe engine shutdown.

Note! If the Overspeed Shutdown has

been disabled in the configuration,

then this test will NOT generate a

shutdown.

Deactivate

The Overspeed Test times out after 5

minutes, or when an actual overspeed

situation is observed.

The test can also be turned off by

selecting the menu item again.

Connect a PC

To connect to the DCU, an Ethernet

cable and a PC or laptop is necessary.

Connect the cable

Connect a standard CAT5 ethernet

cable between the laptop Ethernet port

and the DCU Ethernet port (COM 6).

Matching IP-address range

To connect a PC to the DCU, the IP-

address (IP number) of the PC or

laptop must be in the same ‘range’ as

the IP-address of the DCU.

Often, the IP-address in a laptop is not

available to change by the user due to

company policy.

Whenever the laptop is connected in a

network, it is given a new IP-address.

Normally, the laptop is given a new IP-

address whenever it connects to the

network at work. This scheme is called

dynamic IP-address.

This given IP-address may not match

that of the DCU though.

For this purpose, the DCU has an

inbuilt server component, which

resembles that of the company

network, and gives the laptop an IP-

address that matches the DCU.

On the top of this form is the DCU’s

current IP-address. The next lines

display a start- and end IP-address.

This is the range the DCU’s DHCP

server will scan.

User’s Manual – 400E Series

Page 13

Make sure the DCU IP-address is

outside

the DHCP Start- and End IP-

address range, by setting the start IP

higher or the end IP lower than the

DCU IP-address.

For the example in the figure above, a

Start IP of 192.168.0.110 is OK, whilst

a Start IP of 192.168.0.105 is not.

When the range is fine, then press the

OK button. The DCU’s server will now

give a new IP-address to any laptop

connected to the DCU within the next

10 minutes (timeout period).

The laptop keeps the new IP-address

even after the 10 minute timeout,

which is fine.

Connect to the PC

When the above exercise is done,

connect to the DCU by typing the DCU

IP-address into the browser’s URL

field.

The above picture is representative for

a typical successful login.

Administration

This menu gives access to the next

level of menus, and is not discussed in

this manual.

A four digit pin-code is needed to

access the menu.

Interface Design

Up to four extra instrument screens

can be added by the user.

Note! The webserver can also be used

to add new user screens.

The screen layout

Each screen is built up as follows.

Each screen has a

template

.

There are multiple templates to

choose from, and each screen

can have a different template.

A template is divided into

rectangles called

slots

. A slot is

simply a placeholder for a

widget.

A

Widget

can be a circular dial,

a horizontal bargraph, a

numerical value, etc. To be

used, the widget must fit into

the slot.

User’s Manual – 400E Series

Page 14

Add a user screen

Press ‘Insert new’.

Use the up/down arrow buttons

to select a suitable template.

Press ‘OK’, then ‘Save’.

Now, press ‘Slot Design’ and

‘Edit View’.

Use the arrow up/dn buttons to

select a slot (indicated with a

bold rectangle around it).

Select ‘Pick Signal’. Pick a signal

from the list of configured

signals, for instance Engine

Speed.

Now, press arrow buttons

up/dn again to select another

slot, and repeat the process.

Press softbutton 4 when

finished.

Observe the new screen.

Press the arrow buttons to cycle

between screens.

Delete a user screen

First, select the menu item Interface

Design.

Using the arrow up/dn buttons, select

the screen to be deleted.

Press the Delete button to delete the

screen.

User’s Manual – 400E Series

Page 15

Log & Counters

The engine running hours are available

in this menu.

Events and service intervals are also

available.

Counters

The Counters page display engine

running hours.

Total

The total accumulated engine hours.

Depending on the configuration, the

value is calculated in the DCU, or read

from the ECM.

This counter value cannot be reset by

the operator.

Since Start

This counter starts at zero every time

the engine is started, and counts until

the engine is stopped.

This counter value cannot be reset by

the operator.

Since Reset

This counter accumulates every time

the engine is running.

Press the Reset button to clear the

Since Reset values.

Idle Hours

The idle hours counter counts

whenever the engine is running below

600 rpm.

Event Log

The DCU keeps a log of all events. The

log is about 500 events long, after

which the oldest event is lost.

Note! Using the web server, the entire

log can be downloaded.

An event is defined as any diagnostic,

warning alarm or engine shutdown

situation, but also certain user

interaction such as start- and stop

button.

User’s Manual – 400E Series

Page 16

Event Sorting

The events can be sorted as follows:

Oldest first

Most severe first

Least severe first

Count

Navigation

Use the up and down arrow to

navigate in the event log.

Timestamp

The selected event will be expanded,

and the second line displays the

running hours when the event

triggered.

For alarms, the second line will also

display the running hours for the

acknowledged and inactive events.

Engine Service Interval

Four different service intervals can be

configured.

The DCU indicates with a warning

when a service is past due.

Next Service Interval

Press the Tab button to see the next

service interval.

Service Done

Press this button when the service has

been completed. The counter restarts.

The Service done operator event

appears in the event log.

Select J1939 Node

DM2 is stored trouble codes according

to SAE J1939, and the DCU can retrieve

stored DTCs / DM2 from a J1939

node. It needs to select J1939 node.

User’s Manual – 400E Series

Page 17

Screen Backlight

Select the desired backlight intensity.

Note that if 10% is selected, the DCU

will still switch to 50% backlight

intensity while in the menu.

Help

The help menu has information about

the panel and troubleshooting

information.

Troubleshooting

The DCU has a comprehensive

troubleshooting screen for the DCU,

and also for each of the optional

expansion units.

This manual suits for next models

1

Table of contents

Other auto maskin Marine Equipment manuals

auto maskin

auto maskin Marine Pro 400 Series User manual

auto maskin

auto maskin Marine Watch S Series User manual

auto maskin

auto maskin Marine Pro 400 Series User manual

auto maskin

auto maskin Marine Pro 200 Series User manual

auto maskin

auto maskin Marine Pro 200E Series User manual

auto maskin

auto maskin LT Series User manual

auto maskin

auto maskin Marine Pro 400 Series User manual

auto maskin

auto maskin S Series User manual

auto maskin

auto maskin Marine Pro 400 Series Instruction sheet

auto maskin

auto maskin 1006451 User manual