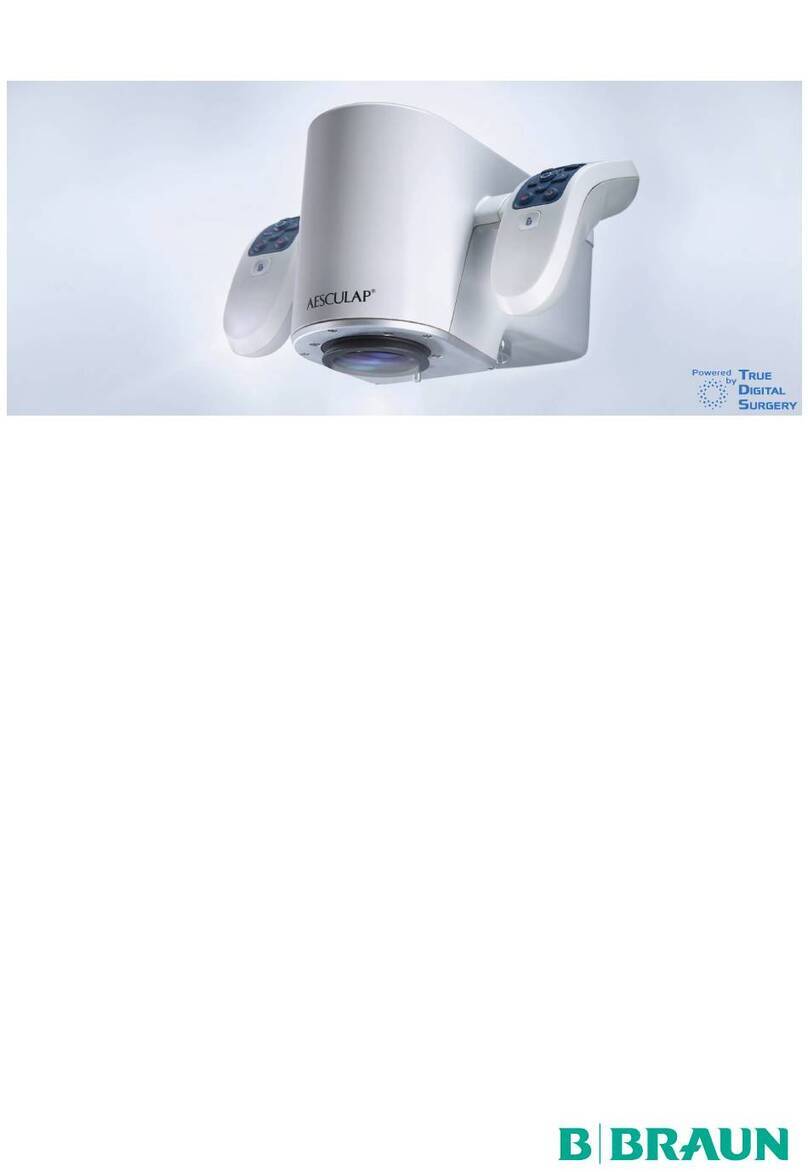

Aesculap Neurosurgery

MINOP TREND (TRansnasal ENDoscopy System)

14

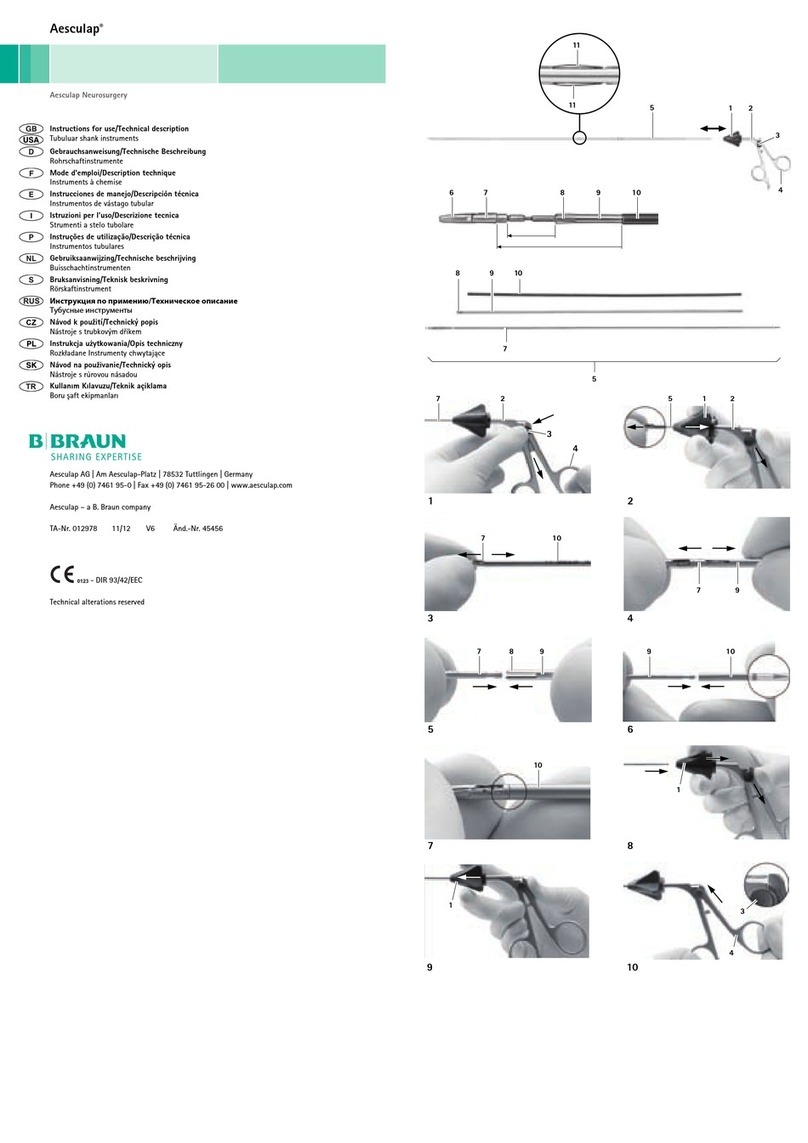

Control, care and inspection

¾Allow the product to cool down to room

temperature.

¾Lightly lubricate movable parts (irrigation sheath

lock, irrigation button, handle cone) with

maintenance oil suitable for the respective

sterilization process (e.g. Aesculap STERILIT® Spray

JG600 or maintenance oil JG598).

¾Assemble the separable product, see Assembling.

¾Inspect the product after each cleaning and

disinfecting cycle to be sure it is clean, functioning

properly, not damaged, has intact insulation and

does not have any loose, bent, broken, cracked,

worn, or fractured components.

¾Check for compatibility with associated products.

¾Set aside the product if it is damaged.

Packaging

¾Appropriately protect products with fine working

tips.

¾Sort the product into its appropriate storage device

or put it on a suitable tray.

¾Package trays appropriately for the sterilization

process (e.g. in Aesculap sterile containers).

¾Pack the product in such a way that the packaging

will prevent recontamination of the product in the

period between reprocessing and reuse.

Sterilization method and parameters

Note

The product can be sterilized either in disassembled or

in assembled condition.

¾Make certain that all external and internal surfaces

will be exposed to the sterilizing agent (e.g. by

opening all valves and faucets).

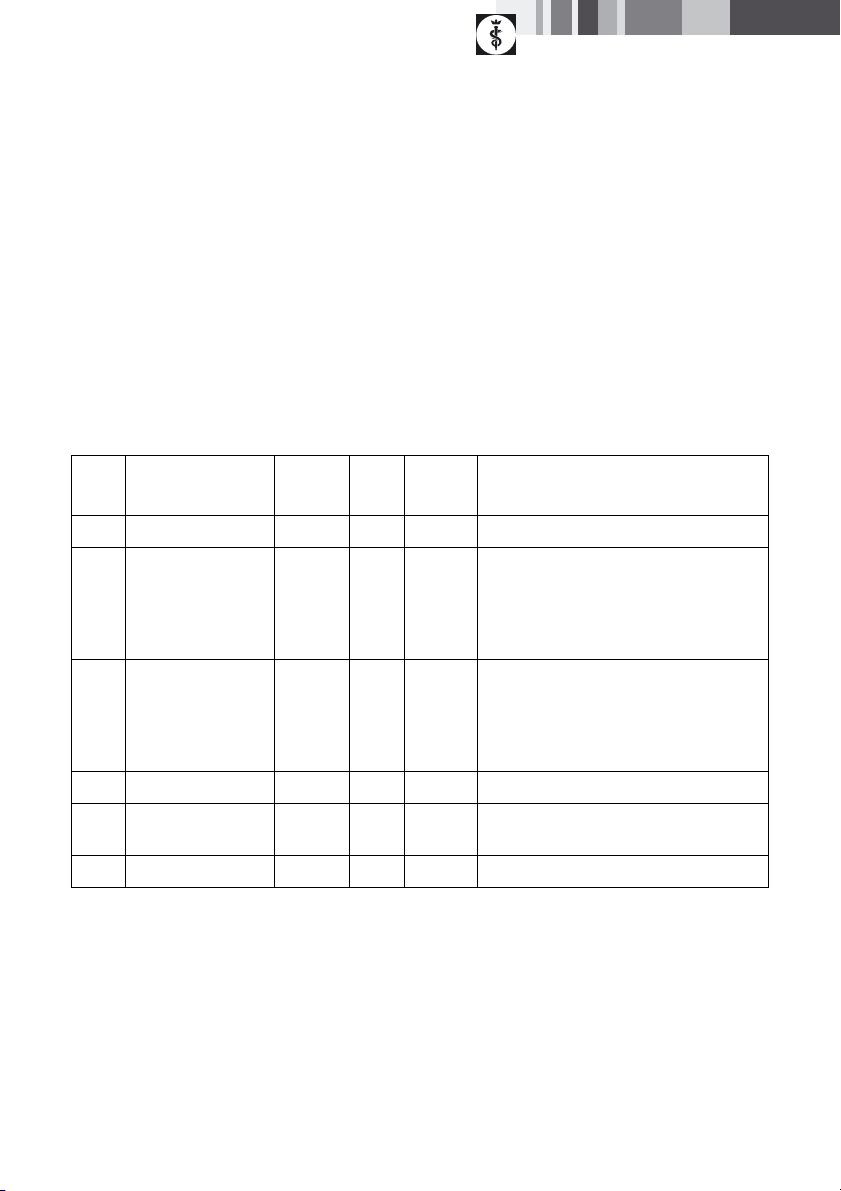

¾Validated sterilization process

– Steam sterilization through fractionated vacuum

process

– Steam sterilizer acc. to EN 285/ANSI/AAMI/

ISO 11134-1993, ANSI/AAMI ST 46-1993,

validated acc. to EN 554/ISO 13683

– Sterilization through fractionated vacuum process

at 134 °C/holding time 5 min

¾When sterilizing several products at the same time

in one steam sterilizer: Make certain that the

maximum allowable load capacity of the steam

sterilizer, as specified by the manufacturer, is not

exceeded.

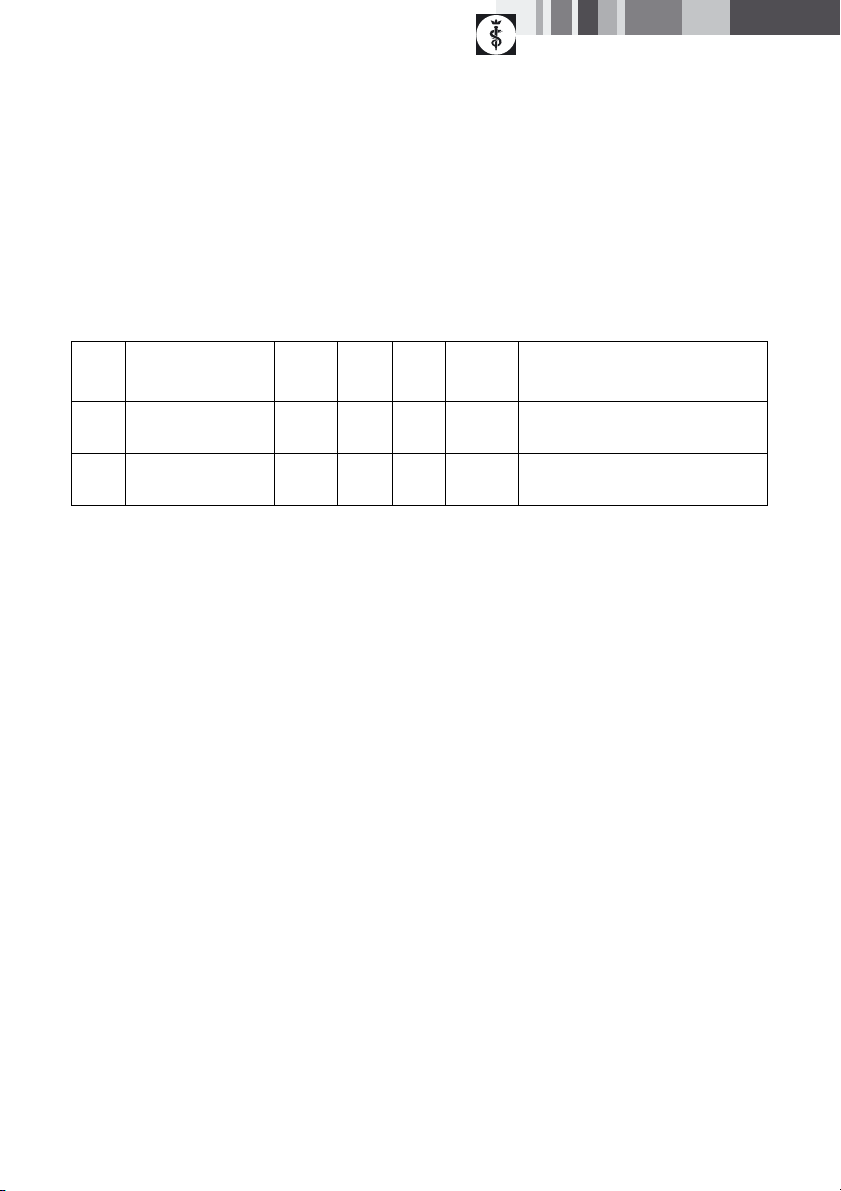

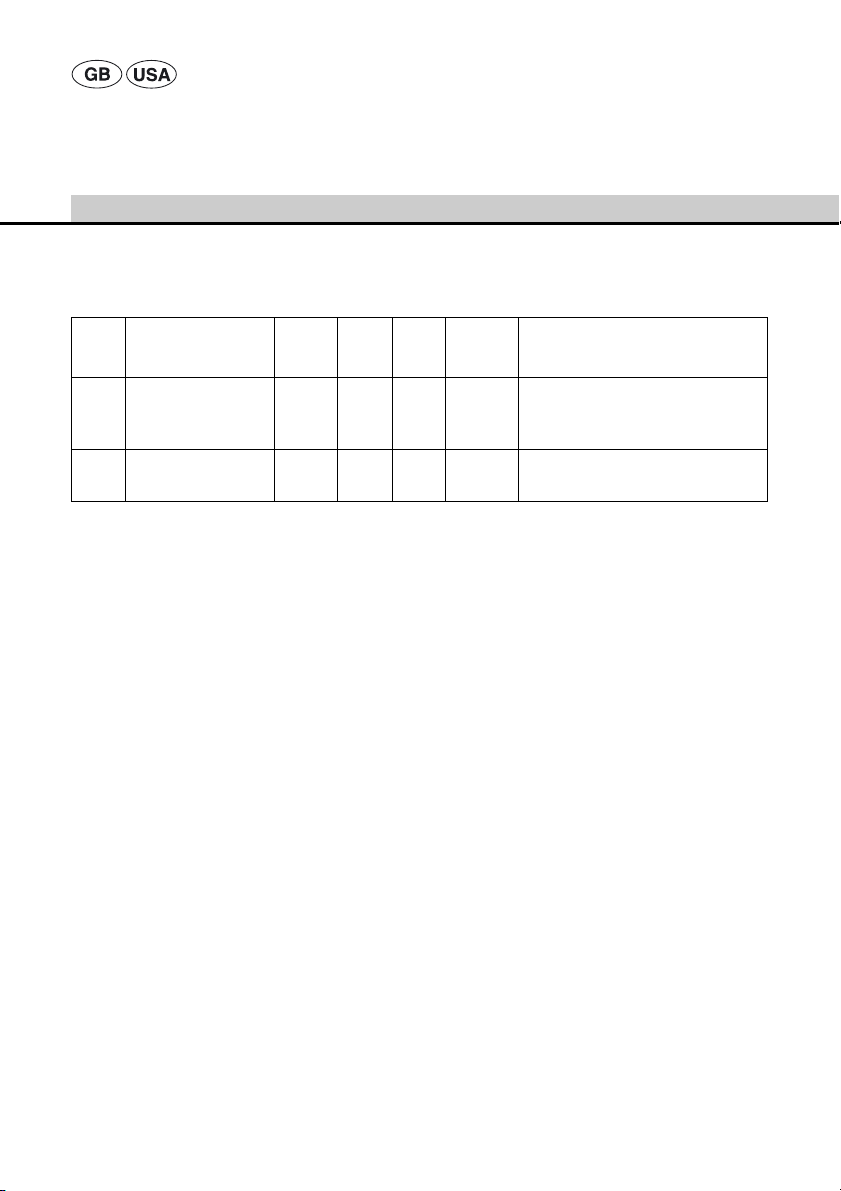

Sterilization for the US market

• Aesculap does not recommend the device sterilized

by flash or chemical sterilization.

• Sterilization may be accomplished by steam auto-

clave in a standard prevacuum cycle.

To achieve a sterility assurance level of 10-6, Aesculap

recommends the following parameters:

*Aesculap has validated the above sterilization cycle

and has the data on file. The validation was accom-

plished in an Aesculap Sterilcontainer cleared by FDA

for the sterilization and storage of these instruments.

Other sterilization cycles may also be suitable, how-

ever individuals or hospitals not using the recom-

mended method are advised to validate any alternative

method using appropriate laboratory techniques. Use

an FDA cleared accessory to maintain sterility after

processing, such as a wrap, pouch,etc.

WARNING for the US market

If this device is/was used in a patient with, or sus-

pected of having Creutzfeldt-Jakob Disease (CJD),

the device cannot be reused and must be destroyed

due to the inability to reprocess or sterilize to elim-

inate the risk of crosscontamination.

Aesculap Orga Tray/Sterilcontainer (perforated

bottom)

Minimum cycle parameters*

Sterilization

method

Temp. Time Minimum

drying time

Pre-vacuum 132 °C

(275 °F)

4 min 20 min