Installation Manual

www.bluecorner.be 4

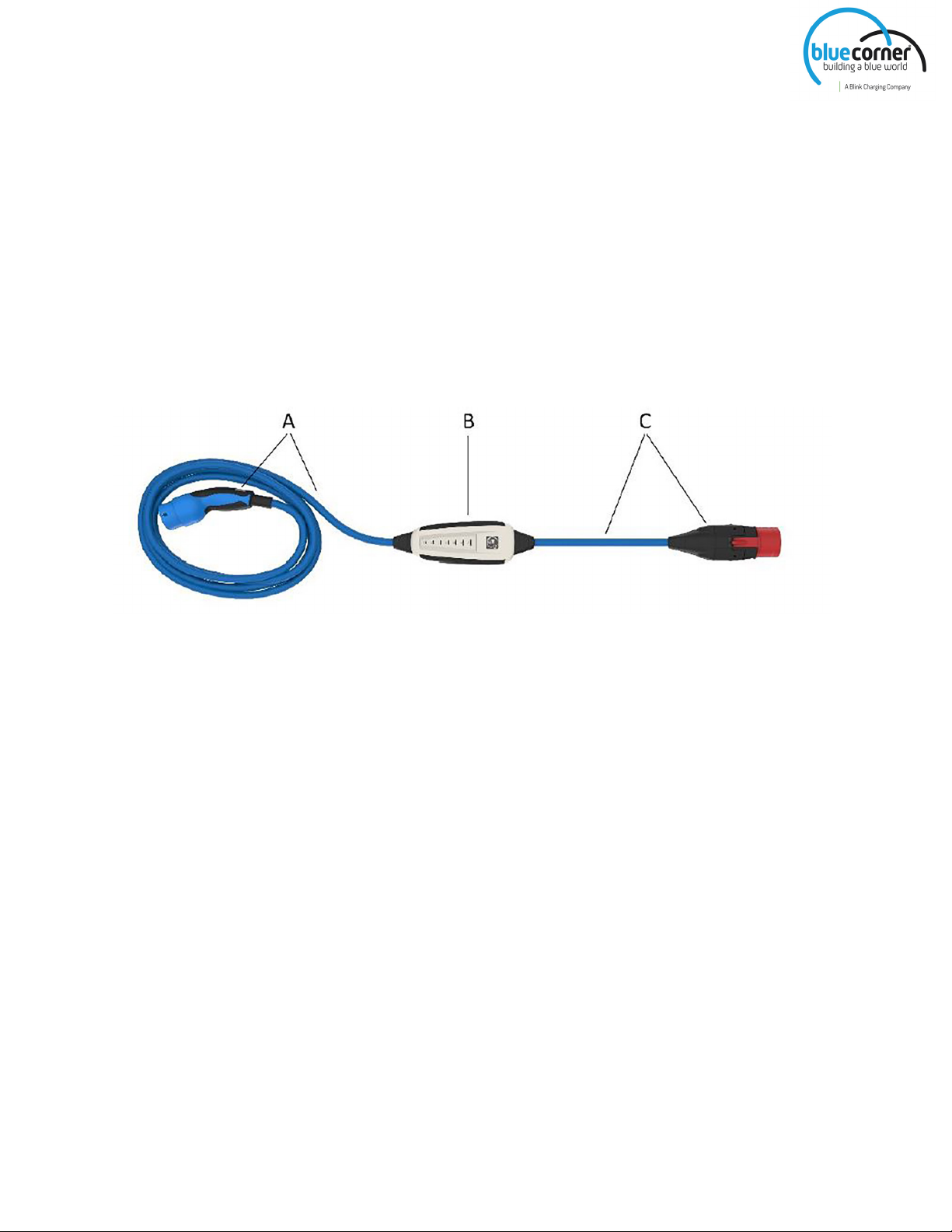

When removing the cable from the socket pull on the Connector System, never the cable!

Protect the charging unit and the charging cable from mechanical damage (running over, pinching or kinking)

and the electrical contact area from heat sources, dirt and water!

Note that the Smart Attachments must be fitted with the IP 24 protective cover supplied when not connected in

order to provide a sufficient IP protection level.

Only use Smart Attachments and accessories supplied by Blue Corner with the charging unit or those that are

approved by Blue Corner.

The Smart Attachments contain a Neodymium magnet which may not be brought into direct body contact with

heart pacemakers out of safety reasons.

PQ 150 contains telecommunication hardware which may not be brought into direct body contact with heart

pacemakers out of safety reasons.

In the following countries the charging current may not be set higher than 10A if a Schuko adapter plug is used:

Norway

In the following countries the charging current may not be set higher than 8A if a Schuko adapter plug is used:

Finland, France and Switzerland

In the following countries the charging current may not be set higher than 6A if a Schuko adapter plug is used:

Denmark

If a Schuko Smart Attachment is used, the weight of the charging unit must not put strain on the socket. Relieve

the strain on the cable (e.g. by placing the unit on something or hanging the cable over a hook).

During a single phase charging operation within a 3-phase-grid, the requirements of the grid operator for

asymmetric grid loads needs to be considered. The charging power may not be set to a higher value than the

maximum single phase power drain permitted by the grid operator.

3. INTENDED USE

The charging and all included accessories unit may only be used to charge the drive battery of an electric or

plug-in-hybrid vehicle. Section 5 ”Product Description” describes operation of the charging unit.

Any other use will be considered as improper use. Blue Corner does not assume liability for any damage that

results from such improper use!

Intended use includes following the instructions in this manual as well as observance of all labeling such as type

plates,warning notices, current limit marks, display symbols and ambient conditions.