Instruction Manual

CRSG 12-28 05

Index

BALDAN WARRANTY .............................................................................................................. 07

GENERAL INFORMATION....................................................................................................... 08

To the owner ................................................................................................................................. 08

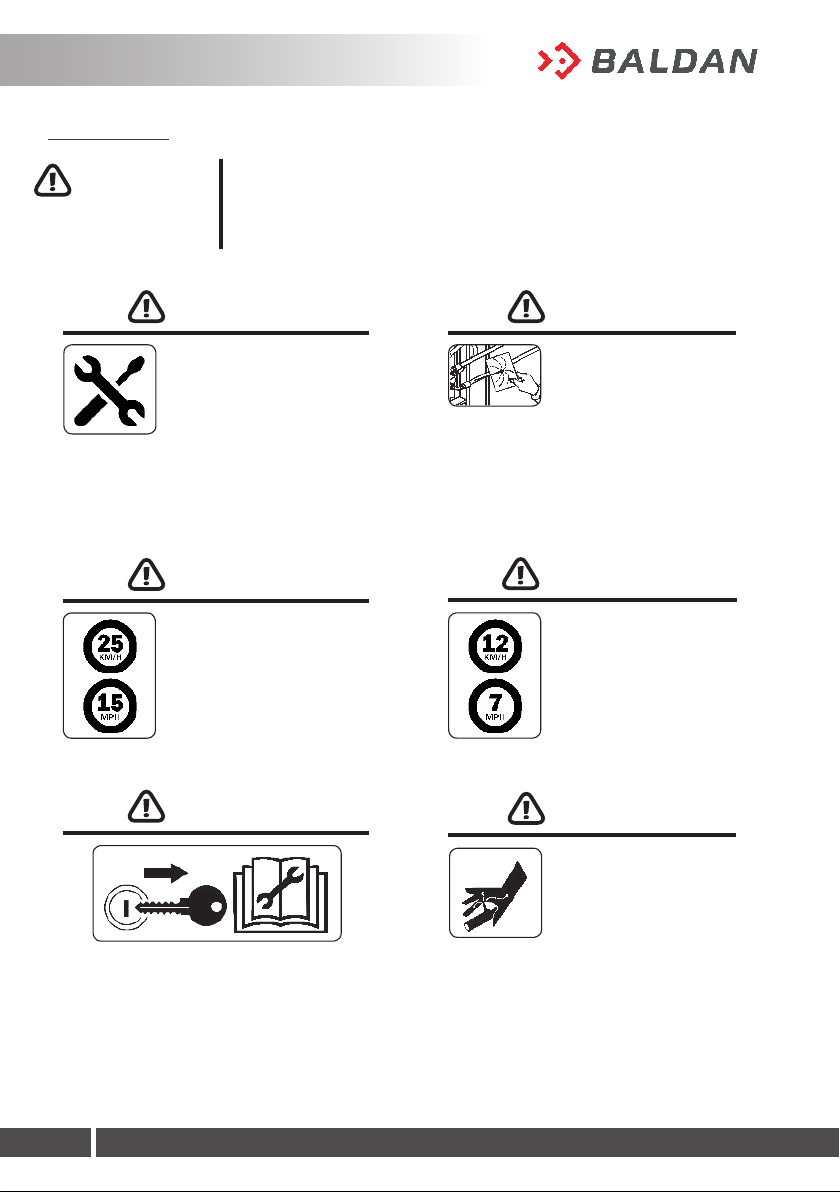

SAFETY RULES.......................................................................................................................... 09

To the operator.............................................................................................................................. 09 - 12

WARNINGS ..............................................................................................................................

COMPONENTS......................................................................................................................... 15

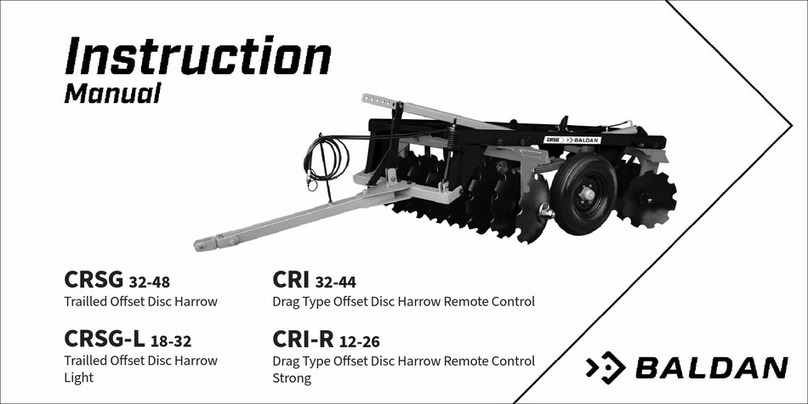

CRSG - Trailled Offset Disc Harrow .............................................................................................. 15

DIMENSIONS........................................................................................................................... 16

CRSG - Trailled Offset Disc Harrow .............................................................................................. 16

SPECIFICATIONS...................................................................................................................... 17

CRSG - Trailled Offset Disc Harrow .............................................................................................. 17

ASSEMBLY................................................................................................................................ 18

Wrench set .................................................................................................................................... 18

Assembly disc sections.................................................................................................................. 19

Assembly disc sections - CRSG 12, 14 and 16 discs..................................................................... 20

Assembly disc sections - CRSG 18, 20 and 22 discs..................................................................... 21

Assembly disc sections - CRSG 24 and 28 discs........................................................................... 22

Assembling frames to the studs................................................................................................... 23

Assembling disc sections on the frames...................................................................................... 24

Assembling the wipers.................................................................................................................. 25

Assembling wheel shaft holder ................................................................................................... 26

Assembling tires ........................................................................................................................... 27

Assembling hydraulic cylinder .................................................................................................... 28

Assembling coupling head ........................................................................................................... 29

Assembling stabilizer bar ............................................................................................................. 30

Assembling hydraulic hoses ........................................................................................................ 31

HICTH........................................................................................................................................ 32

Harrow coupling to tractor drawbar .......................................................................................... 32

LEVELING ................................................................................................................................. 33

Harrow leveling - Part I................................................................................................................. 33

Harrow leveling - Part II................................................................................................................ 34

ADJUSTMENTS ........................................................................................................................ 35

Adjustment for transport ............................................................................................................. 35

Harrow opening adjustment........................................................................................................ 36

Working depth adjustment .......................................................................................................... 37

Harrow displacement regulation - Part I .................................................................................... 38

Harrow displacement regulation - Part II ................................................................................... 39