01. Safety rules.................................................................................................................................................................................................................................................................. 4 - 8

02. Components............................................................................................................................................................................................................................................................... 9

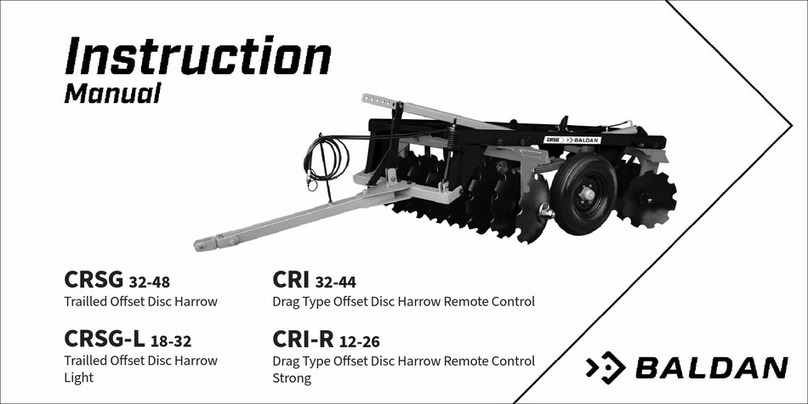

03. Technical specications - CRSG ............................................................................................................................................................................................................................. 10

04. Technical specications - CRI ................................................................................................................................................................................................................................. 11

05. Technical specications - CRIR ............................................................................................................................................................................................................................. 12

06. Assembly ..................................................................................................................................................................................................................................................................... 13 - 15

Assemble of front and rear gang ....................................................................................................................................................................................................................................................................... 16 - 17

Mounting of the hydraulic system and articulating wheel assembly CRI/CRSG 12 - 28 models with single wheels....................................................................................................................................... 18

Mounting of the hydraulic system and the articulating wheel assembly CRI/CRSG 32 - 48 models with dual wheels................................................................................................................................... 19

CRI/CRSG 32 - 48 models with large single wheel version................................................................................................................................................................................................................................ 20

Mounting of the hitch system............................................................................................................................................................................................................................................................................ 21-22

07. Hitching to the tractor.............................................................................................................................................................................................................................................. 22

08. Adjustments and operations.................................................................................................................................................................................................................................. 23

Transport ........................................................................................................................................................................................................................................................................................................... 23

Transport / Work................................................................................................................................................................................................................................................................................................ 23

Disk Harrow Gangs Adjustments....................................................................................................................................................................................................................................................................... 24

Displacement Adjustment................................................................................................................................................................................................................................................................................. 24

Hitch Transversal Bar Adjustment ..................................................................................................................................................................................................................................................................... 25

Operations ......................................................................................................................................................................................................................................................................................................... 26

09. Lubrication.................................................................................................................................................................................................................................................................. 27

10. Lubrication Points ..................................................................................................................................................................................................................................................... 28 - 29

11. Bearing adjustments ................................................................................................................................................................................................................................................ 30

12. Cleaning....................................................................................................................................................................................................................................................................... 30

13. Hourly production of the CRSG/CRI/CRIR......................................................................................................................................................................................................... 31 - 33

14. Identication .............................................................................................................................................................................................................................................................. 34 - 35

INDEX