75.5911.02 20180226 Page 8 of 9

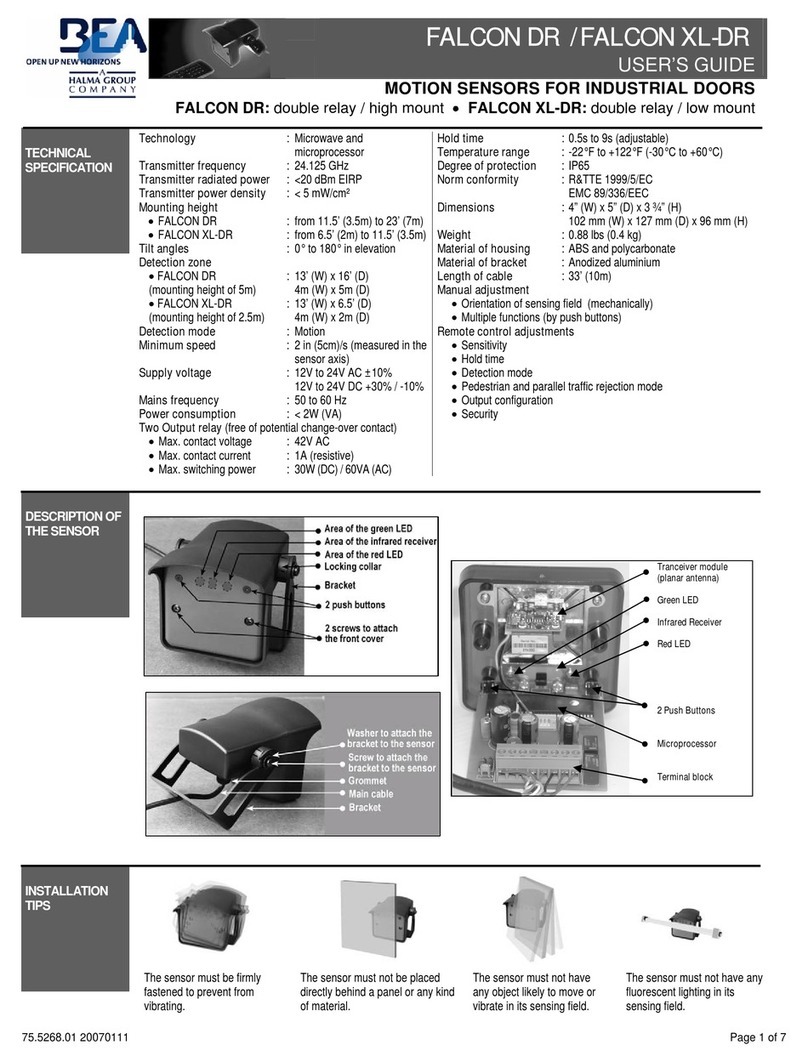

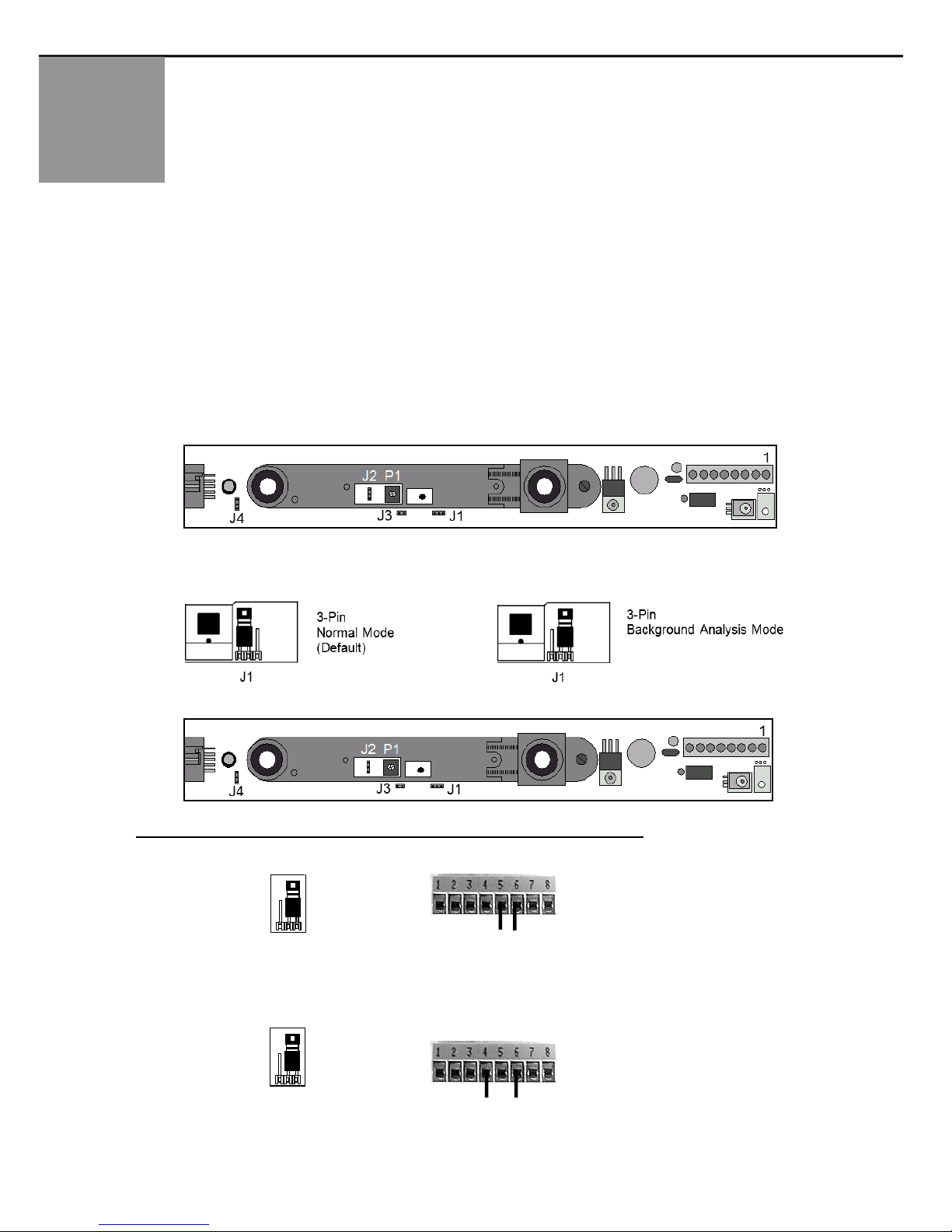

3. The following procedures will be used to adjust each module’s detection zone upon power-on, and must be made with the

Background Analysis jumper set to ‘Normal Mode’ (see page 5).

a. Power the sensors with 12 – 24 VAC/VDC ±10%. LED status should reflect what was configured for the relay output

(see page 6)

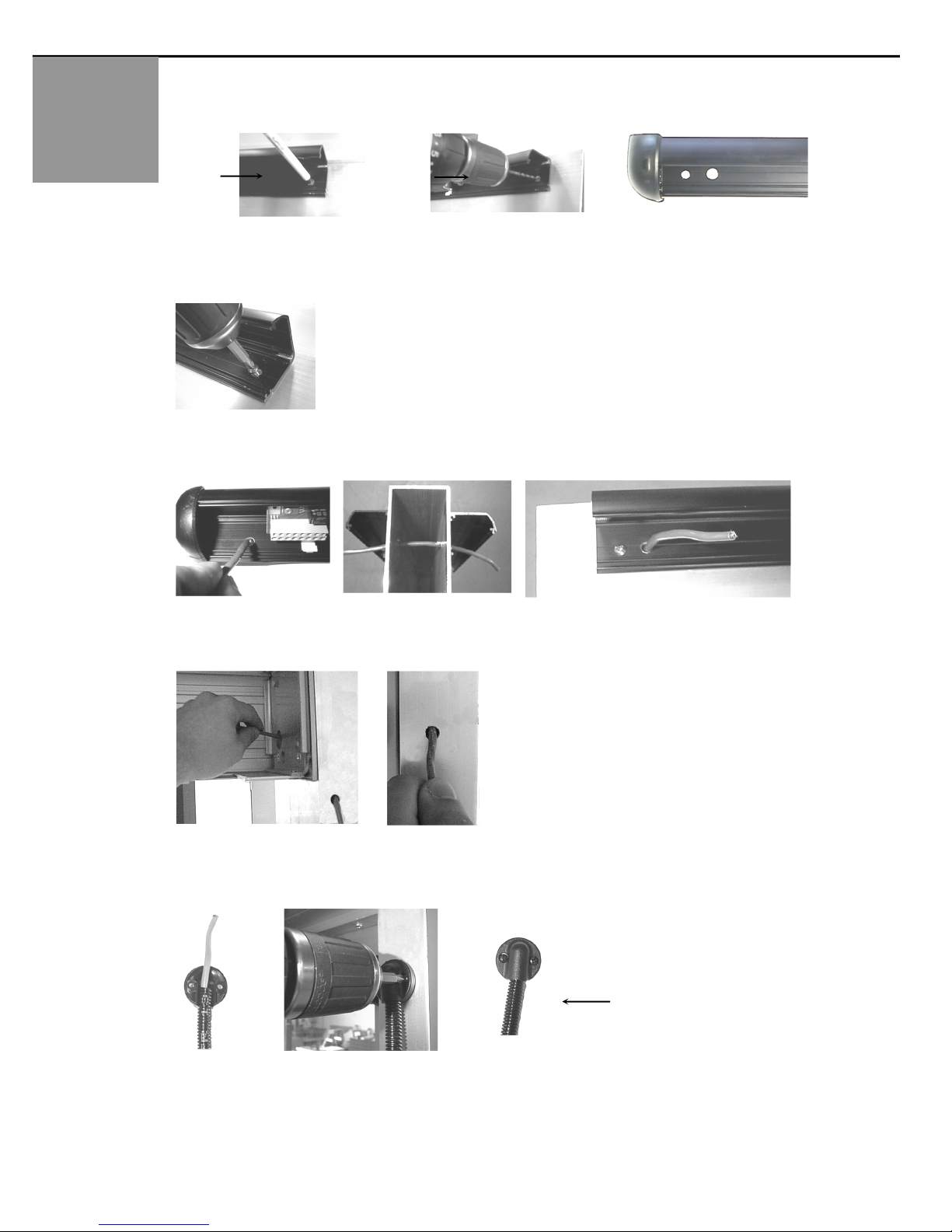

b. Use a white, gray, or black piece of cardboard about 8" x 11" and hold it as shown in the diagram in step 2 of this

section (previous page).

c. Move the cardboard from the floor upward until it is detected. This will determine the height of the inactive area (B

distance).

d. Measure the height at which the cardboard was detected.

e. If this height does not fall between 12" – 16" above the floor or does not meet your requirements, an adjustment must

be made to the detection distance. One notch of the distance adjustment corresponds to approximately 4".

- If Zone B is too high, turn the distance adjustment clockwise to increase the detection distance and decrease

Zone B.

- If Zone B is too low, turn the distance adjustment counter-clockwise to decrease the detection distance.

Per current ANSI A156.10, 156.27 the detection zone must be within 28” of the floor. Ideally, each detector should

be adjusted so that detection occurs at 12” – 16” above the floor. Less than 12” of Zone B may result in occasional

false triggering of the sensor.

f. Once all sensors have been adjusted, activate the door several times and allow it to go through a full cycle each time.

Ensure that no false triggering is occurring, as would be indicated by the door re-cycling or stopping by itself at any

point of travel.

g. Ensure compliance of all applicable safety standards (i.e. ANSI A156.10, 156.27).

h. Install all remaining covers, endcaps, screws, etc.

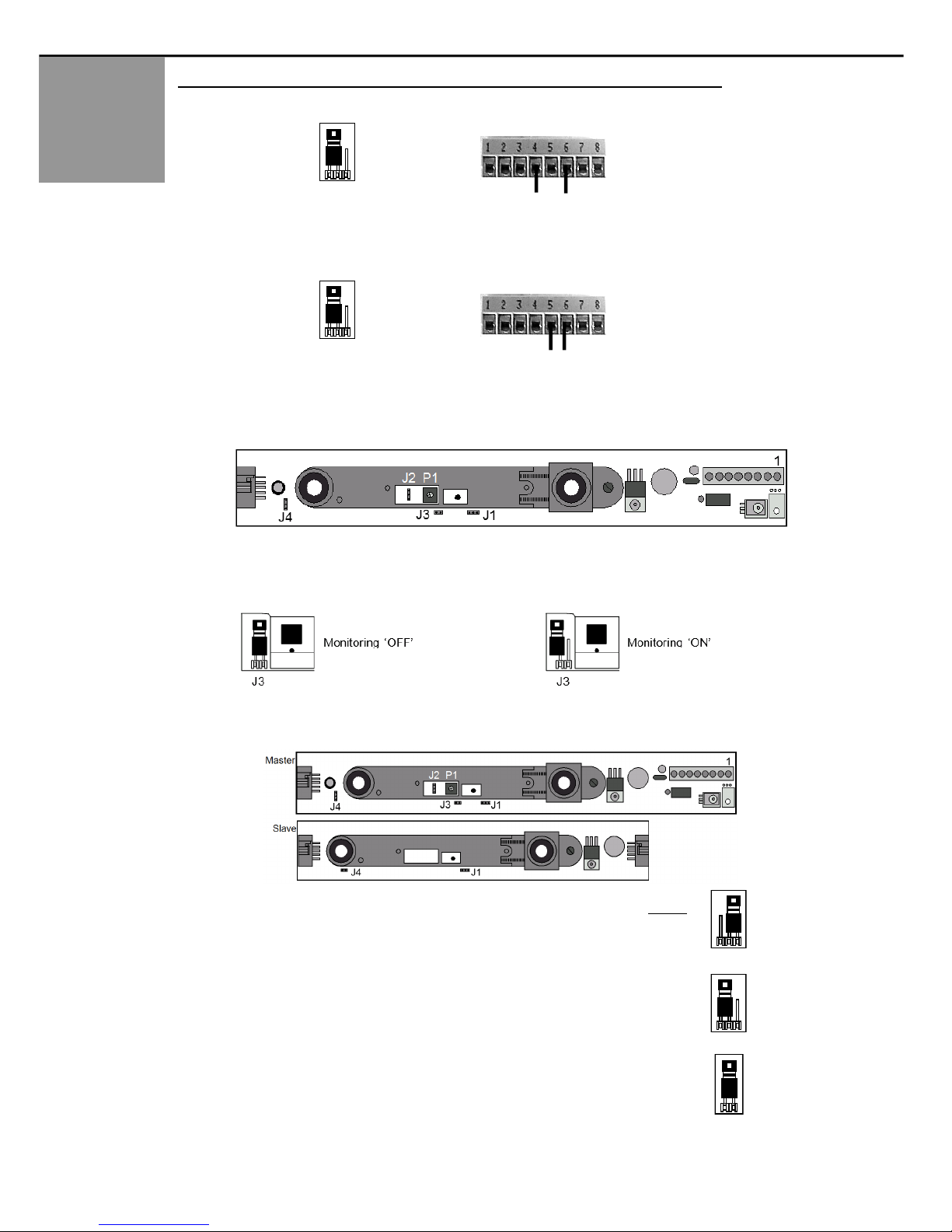

When using monitoring and non-monitoring modules in the same chain, observe the following rules:

• Non-monitoring Master modules CANNOT be used with monitoring Slave modules.

• All other combinations will work; however, for a system to utilize monitoring, all modules must be monitoring modules

SuperScan-T does not work

at all.

No LED indications.

Faulty power supply

Faulty connections

Power supply must be 12 – 24 VAC/VDC ±10%.

Check for this power at terminals 7 and 8 of the affected

SuperScan-T module.

SuperScan-T output appears

to be working opposite of

what is expected.

Relay output may be configured

improperly

Observe the LED indications on the affected modules to help

determine status.

Door stops by itself before

reaching the full-open

position.

Safety-side SuperScan-T may be

seeing an adjacent wall or rail behind

the door near the open position

Observe the LED status on safety side of door. Find the

SuperScan-T module that is being falsely triggered. Check

for:

ü Proper detection angle

ü Detection range adjustment

SuperScan-T may need to be inhibited at a specific point of

door travel at the safety side for proper operation. Refer to

the terminal connections on page 4.

Activation or safety is being

held triggered.

SuperScan-T detection module may

be seeing the floor or unwanted

object near door

Reduce the detection range on the affected module(s).

Detection should occur at 12” to 16” above the floor. Refer to

step 3 in “Mechanical Adjustments – Positioning & Angling

Modules” (above).

Erratic detection behavior is

occurring throughout the

door’s opening and closing

cycle.

Possible faulty wiring at door transfer

location

Using a multi-meter, check each wire for continuity at the

transfer location. Move the wires around during testing to help

locate any breaks. Replace faulty wiring as necessary.

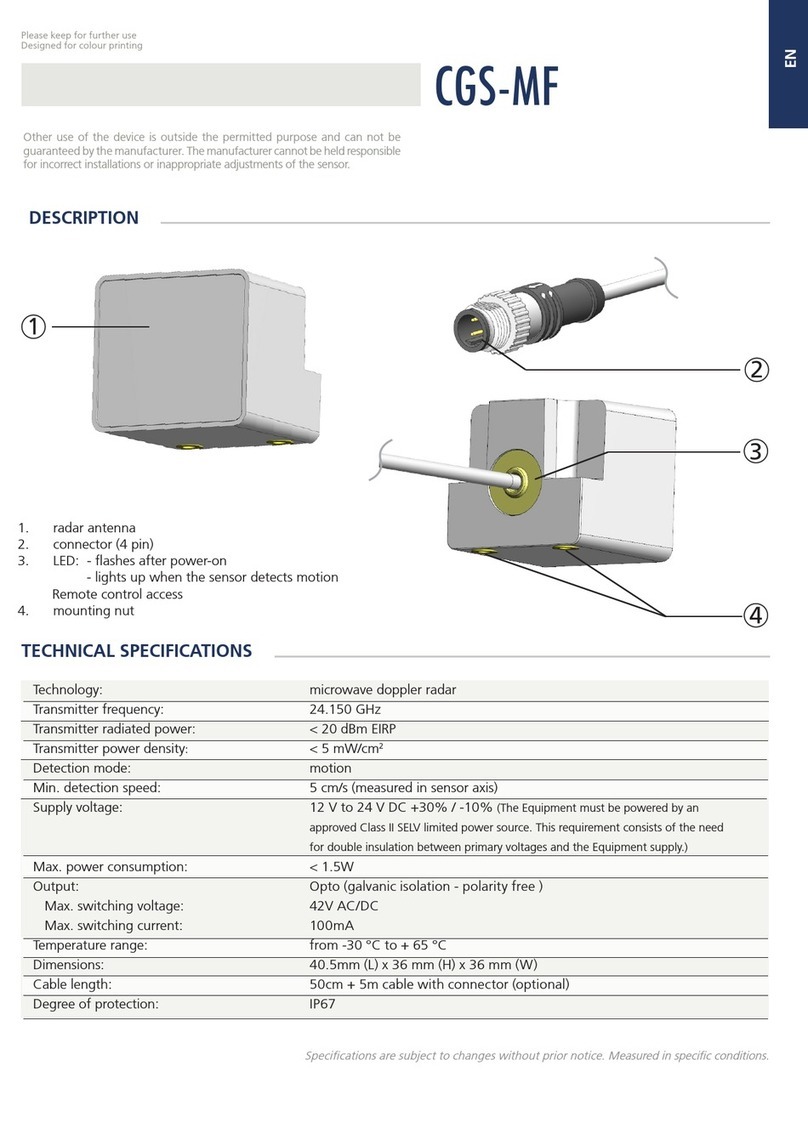

Detection Distance Adjustment

MONITORING &

NON-MONITORING

COMPATIBILITY

MECHANICAL

ADJUSTMENTS

POSITIONING AND

ANGLING THE

MODULES