other connected devices (overall control), regardless of their configuration

(master or slave).If a system requires more than 8 zones, it is possible to

define different addresses from 8 to 127 using the UNIPRO universal

programmer and setting the number of the zone in the advanced parameter

“Address 1”. In this case, the address programmed using the UNIPRO will

prevail over the one programmed using the DIP switches. To return to the

configuration function using the dip switches, set the advanced parameter

“Address 1”to 0, using the UNIPRO, or erase the memory completely as

described below (in this case all information stored in the board will be

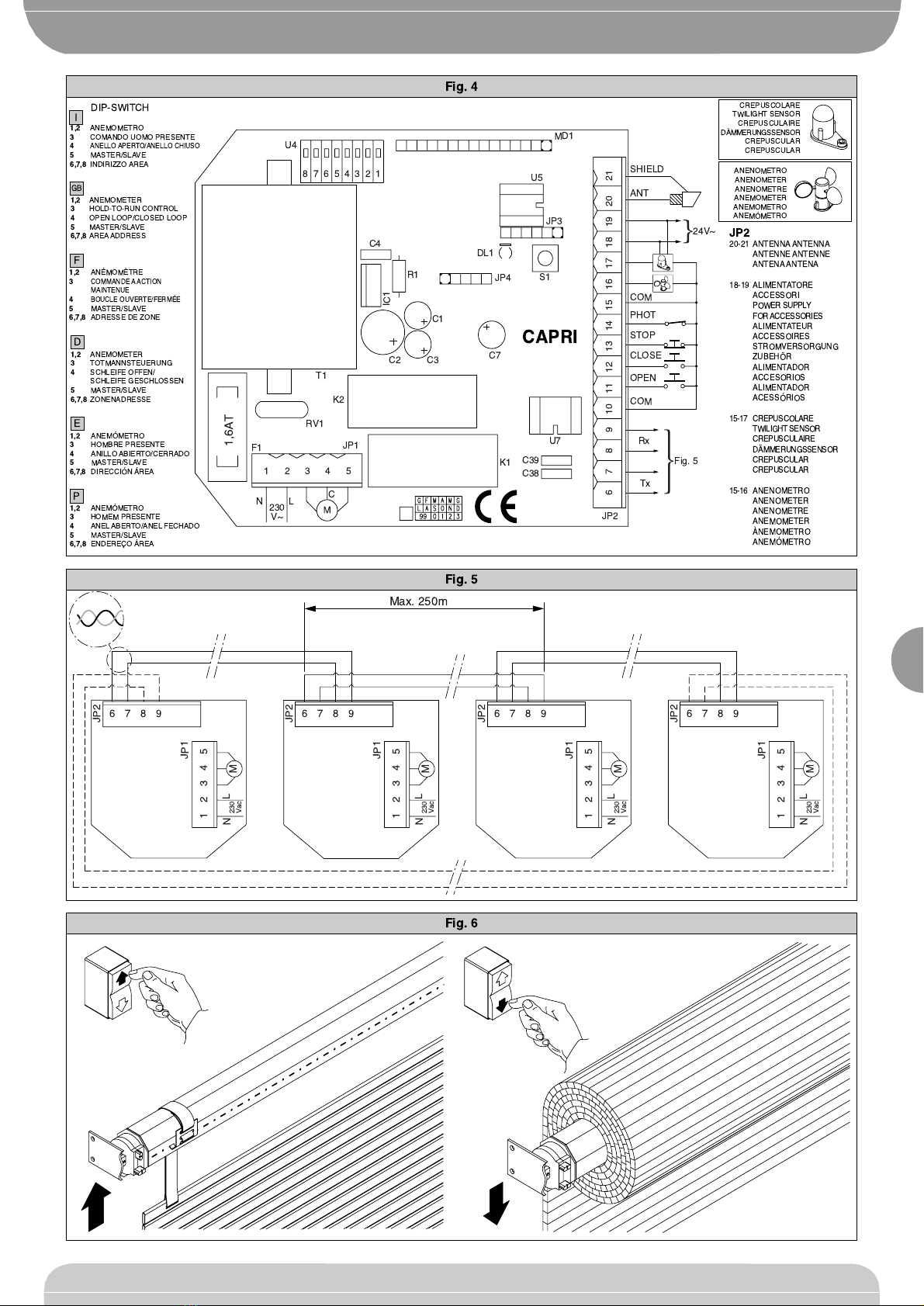

erased). A centralized wire system can be created both by closing the loop

(carrying out the connections marked with a broken line in fig.5 and setting

to ON the dip switch n°4 of the master boards), or by leaving the loop open

(without carrying out the connections marked with a broken line in fig.5 and

leaving on OFF the dip switch n°4 of all boards).

When the loop is closed, each zone master checks the execution of the

commands by the slave boards and updates a part of the statistics relating

to the loop composition. The unsuccessful commands will be repeated after

a few minutes. When the loop is open, these operations are not possible

while all the other functions remain unaltered. The panels preset for radio

control can also be connected via wire. In this case, and when they are

defined as master, or overall control master devices, only the centralised

radio controls related to the T2, T3 and T4 keys (stop, open and close) are

sent via cable, whereas the T1 key (four-step logic) operates locally and is

not sent via cable.

NOTE: The maximum number of devices, including master and slave

types, which can be connected to an individual network, is equal to 255,

consequently a master panel can control up to a maximum of 254 slave

panels.

In the case of installations with a high number of slave panels, the

transmission delay of a command sent by the master to the subsequent

slave device is about 0.5s. Therefore, to give an example, the 50th slave

panel on the line will have a delay in executing the command of about 25s

with respect to the master panel.

7) ANEMOMETER CONFIGURATION

The anemometer can be connected as described in paragraph 4 (fig.4) to

obtain the automatic closure when the wind speed is greater than a certain

preset threshold. The threshold causing the anemometer to step in is set by

using the DIP switches n°1 and 2. The table given below shows the

approximate speed of the wind corresponding to the threshold relating to

theaccessory P111182 (anemometer performing 2impulses per revolution):

Dip n°1 Dip n°2Threshold Hz m/s km/h

OFF OFF 11,5 4,2 15

OFF

ON

ON

ON

OFF

ON

23

35

47

8,4

12,6

16,8

30

45

60

The control of the anemometer on the master board acts in a

centralized way, while the controls of the anemometer on the slave

boards act locally.

8) TWILIGHT SWITCH

It is possible to connect a twilight switch (see paragraph and fig.4).

The closure of the twilight switch contact originates a closing command in

the actuator. When the contact re-opens, it originates an opening command

in the actuator. The twilight control of the master board acts in a centralized

way, while the twilight commands of the slave boards only act locally.

9) SAFETY DEVICE

In case of automatic or semi-automatic control, it is possible to connect a

safety device (see paragraph and fig.4) as may be prescribed by the safety

standards. The opening of the contact during the closing phase originates

an opening command. Such a command only acts locally.

The safety device can be supplied with 24Vac power from the terminals 19

and 20 (max 70mA).

10) HOLD-TO-RUN CONTROLS

By setting to ON the dip Switch n°3 the input controls of the board become

hold-to-run controls. In this case, the functions of the receiver and external

sensors are inhibited. In case of a centralized wire system, the command

originated by the serial network are not processed.

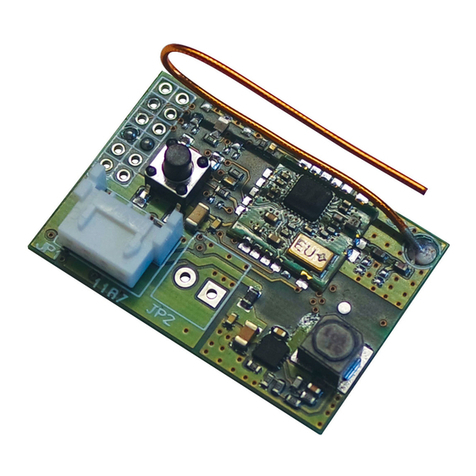

11) RADIO CONTROL (FOR MOD. CAPRI RIC ONLY)

The radio-controls combined with the CAPRI RIC control board, can

feature 1, 2 or 4 keys. The functions of each key are the following:

Key 1: local control with 4-step logic (the first impulse opens, the second

impulse stops on opening, the third impulse closes, the fourth

stops on closing).

Key 2: local and zone stop control.

Key 3: local and zone opening control.

Key 4: local and zone closing control.

11.1) MANUAL PROGRAMMING OF RECEIVER

For receiver programming, press the key S1 located on the Capri board, the

LED DL1 will flash with a frequency of 2Hz to confirm that the transmitters

are operating in the self-learning mode. Press the key hidden by the

transmitters with 1 or 2 keys (see fig.8) within 10 seconds or jump the 4-key

transmitters (see fig.8). The LED DL1 will stay on permanently. Press the

correct key of the transmitter within 10 seconds. When selecting the key,

bear in mind that if the key 1 is pressed after pressing the hidden key, all

the keys of the transmitter are stored in the receiver. If the key 2 is pressed,

the keys 2, 3, 4 will be stored. If the keys of the transmitters are stored

correctly on the different receivers, a centralized system can be obtained

without connecting the control boards to one another. To this purpose, use

single-channel or double-channel transmitters for local commands or four-

channel transmitters for centralized commands. An example is given in

figure 7: the TX1 has been stored using the key 1 on the CAPRI 1 control

unit and using the key 2 on the CAPRI 2 and CAPRI 3 control units.

Furthermore, the transmitter TX2 has been stored in CAPRI 2 control unit

using the key 1 while the transmitter TX3 has been stored in the CAPRI 3

control unit always using the key T1. Under these circumstances, the key

T1 of the transmitter TX1 will control the motor M1 based on the 4-step logic

M1 (local control) and the keys T2,T3 and T4 of the transmitter TX1 will

control stopping, opening and closing of all the 3 motors respectively

(centralized control). The transmitters TX2 and TX3, on the other hand,

perform a local command with 4-step logic onto M2 and M3 respectively.

By repeating the method, it is possible to perform the centralized control of

several zones with great flexibility as far as activation and subdivision are

concerned. Obviously, with this type of centralized control, the commands

sent by wire (opening, closing, stop, photocell, twilight sensor, anemometer

metro) will only be of local nature.

11.2) RADIO PROGRAMMING OF RECEIVER

After manual programming of the first radio-control, it is possible to perform

a radio programming (without having to operate on the control unit again).

To start this programming mode, press the hidden key of a transmitter

already programmed and then press a key on the same transmitter within

10 seconds. In this way, the transmitter operated by the control unit will

switch to self-learning mode and it will be possible to execute all the steps

described for the manual programming of the receiver.

11.3) PROGRAMMING OFTHERECEIVERUSING THEEELINKPROTOCOL

The receiver can also be programmed using the EElinkprotocol, connecting

the UNIPRO terminal by means of the UNIFLAT and UNIDA accessories.

Before connecting the UNIDA accessory to the board, remove the jumper

J1. Upon completion of cancellation, remember to reposition the jumper J1

on pin 1 and 2 of the connector JP3, otherwise the parameters stored in the

board will not be protected from accidental overwriting. The arrangement

of the connections is shown in fig. 8. When programming the receiver make

reference to the instructions for the UNIPRO terminal. Up to 64 radio-

controls can be stored and the control unit can control both standard and

personalized radio-controls. As far as the arrangement of the outputs is

concerned, the control unit CAPRI acts as a 4-channel receiver in which the

outputs have the following functions regardless of the mode programmed:

Output 1: local control with 4-step logic (the first impulse opens, the

second impulse stops on opening, the third impulse closes,

the fourth stops on closing).

Output 2: local and zone stop control.

Output 3: local and zone opening control.

Output 4: local and zone closing control.

The control unit CAPRI does not supply power to the programming

terminal. For transmitter personalization, use the UNITRC and UNIFLAT

accessories and follow the instructions supplied with the programmer.

Note: the personalization of a transmitter acts in an irreversible way

on the code stored therein. The personalized code can be changed but

the transmitter cannot be configurated as standard again.

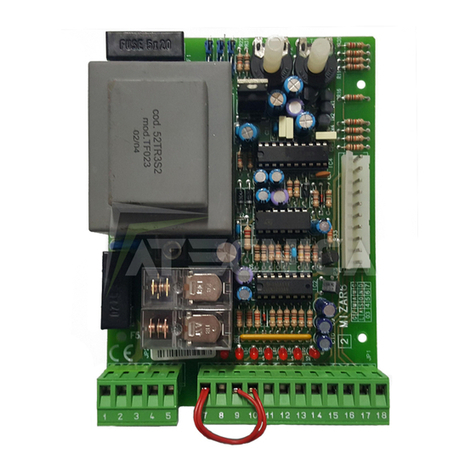

12) ERASURE OF STORAGE

To erase the storage of the board, move the jumper J1 on pin 2 and 3 of

connector JP3, press the key S1 for 10 seconds. The LED DL1 flashes with

a frequency of 5Hz and then stays on permanently for a few seconds until

the storage has been erased. This operation will erase all data from the

board memory, and its configuration will be the same as the original one set

by the manufacturer. Upon completion of cancellation, remember to