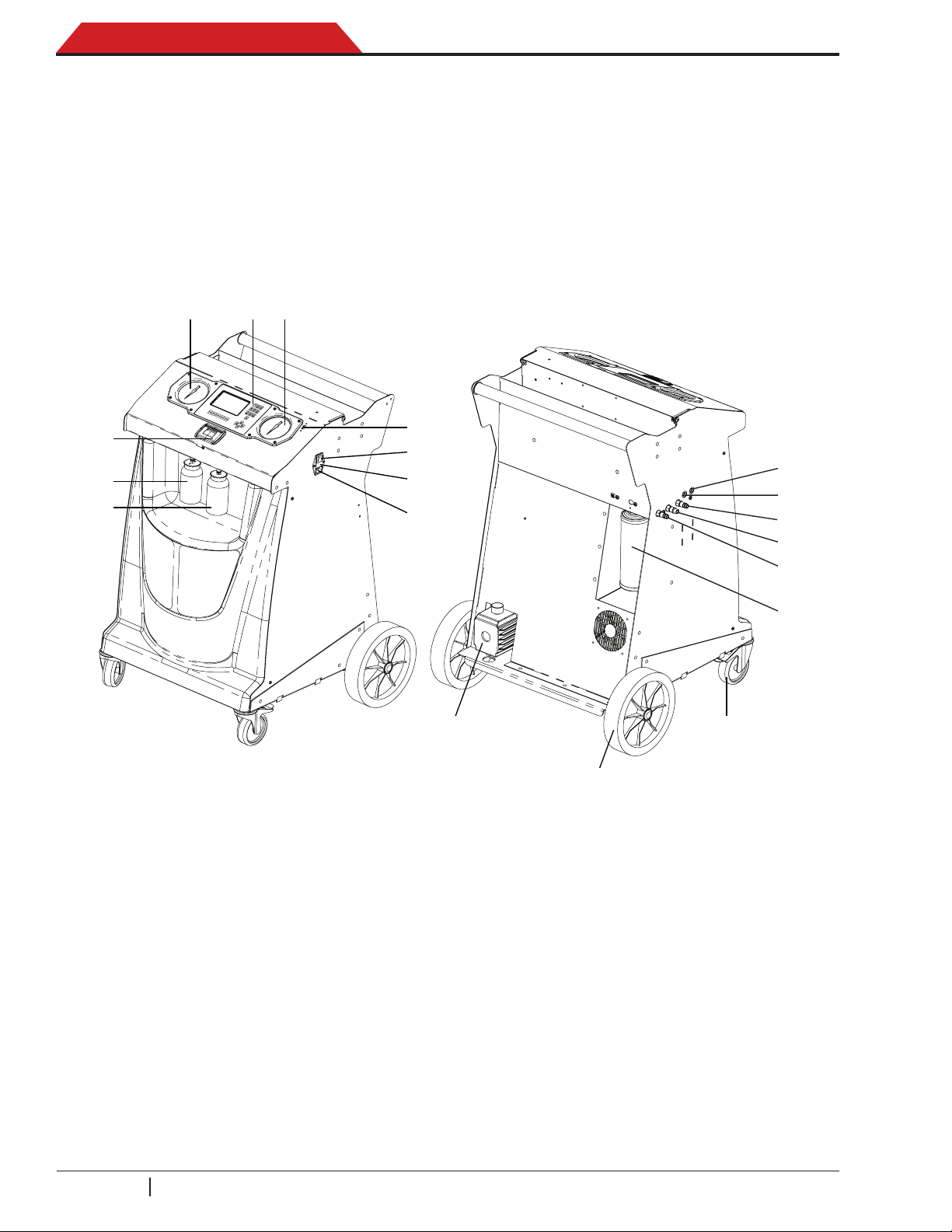

ACS 553, ACS 563 Service Manual

1 689 975 295 2021-04-13Robert Bosch GmbH 5

Beforeoperating

the machine, read and follow all instructions and warnings in this manual. The operator must

be familiar with air conditioning and refrigeration systems, refrigerants, and the dangers of

pressurized components. If the operator cannot read this manual, all operating instructions

and safety precautions must be read and discussed in the operator’s native language.

Using the machine in a manner for

which it was not designed will compromise the machine and nullify the protections provided.

Contact with

refrigerant may cause personal injury, including blindness and frozen skin. Wear protective

Ensure the phase has been completed before disconnecting the machine to prevent the

release of refrigeration to the atmosphere.

Refrigerant

mechanical ventilation that provides at least one air change per hour. If accidental system

discharge occurs, ventilate the work area before resuming service.

Such a precaution

is necessary to prevent the possible presence of refrigerant in the working environment.

The refrigerant R1234yf (for ACS 563 only) is heavier than air and tends to concentrate

in the pits of the workshop.

do not use the machine in the vicinity of spilled or open

with a minimum size of 14 AWG.

hot surfaces.

, do not use the machine in environments containing

D

or areas. Protect the machine from conditions that may cause electrical failure or other

hazards relating to ambient interaction.