BAT 155 | REV. A | October 2020

en |4|Contents

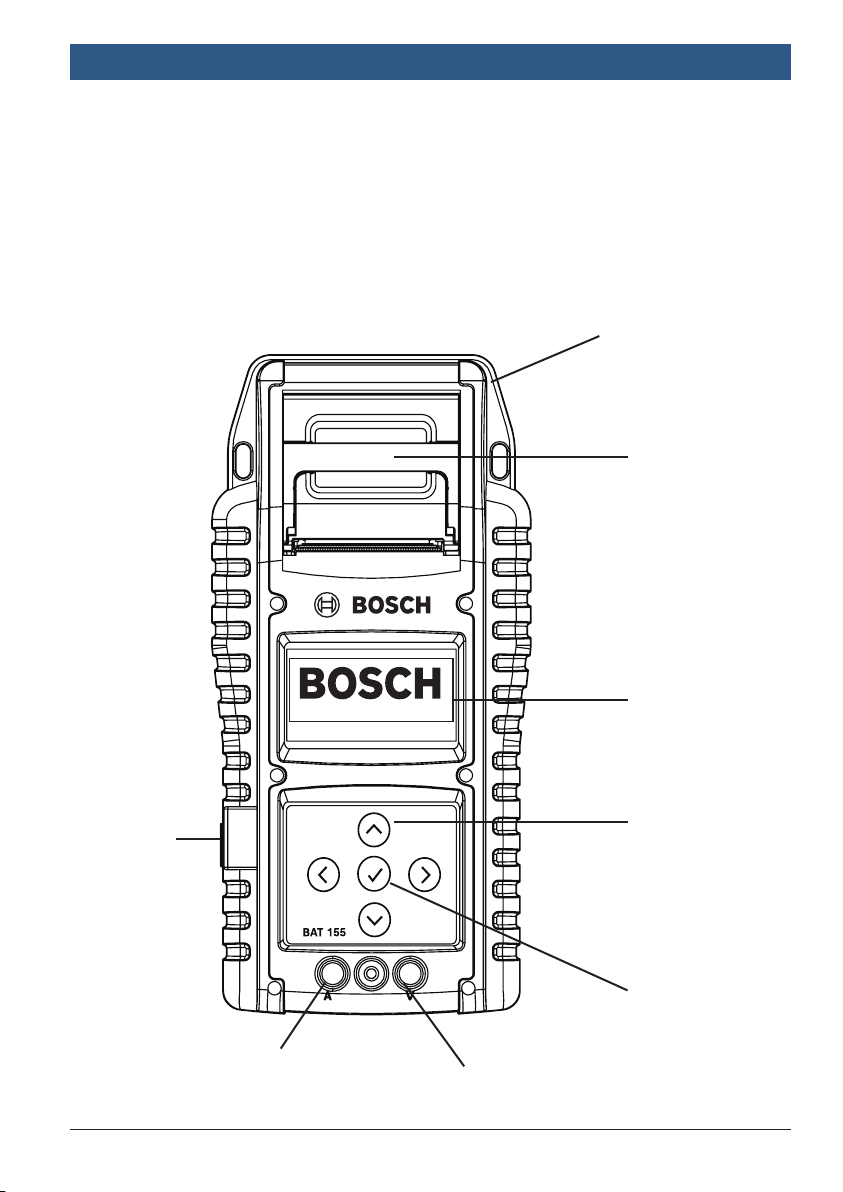

| BAT 155 Battery Tester

2 Safety Warnings and Instructions

WARNING

This product can expose you to chemicals including arsenic, which

is known to the State of California to cause cancer. For more

information, go to www.P65Warnings.ca.gov.

CAUTION

Do not expose the tester to rain or snow.

} Working in the vicinity of a lead acid battery is dangerous. Batteries

generate explosive gases during normal operation. For this reason it is

important that you refer back to these instructions if you have any

questions on tool operation.

} To reduce risk of battery explosion, follow these instructions, those

published by the battery manufacturer, and the manufacturer of any

equipment you intend to use in the vicinity of the battery. Observe

cautionary markings on these items.

} Another person should be within range of your voice or close enough to

come to your aid when you work near a lead acid battery.

} Have plenty of fresh water and soap nearby in case battery acid contacts

skin, clothing, or eyes.

} Wear safety glasses and protective clothing.

} If battery acid contacts your skin or clothing, wash immediately with soap

and water. If acid enters your eye, immediately ood the eye with running

cold water for at least ten minutes and seek immediate medical attention.

} NEVER smoke or allow a spark or ame in vicinity of the battery or engine.

} Be extra cautious to reduce the risk of dropping a metal tool onto the

battery. It could spark or short-circuit the battery or other electrical parts

and could cause an explosion.

} Remove personal metal items such as rings, bracelets, necklaces, and

watches when working with a lead acid battery. These items can produce

a short-circuit current high enough to weld a ring or like to metal causing

a severe burns.