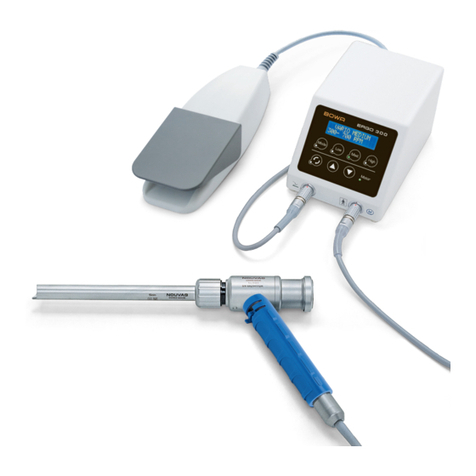

Bowa ERGO 300 Specification sheet

EN ERGO 300 – Morcellator

Information for use

12930 - S0 EN

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

Table of Content

1 General information 4

1.1 Indications 4

1.2 Principle 4

1.3 Contraindications 4

1.4 Target group 4

1.5 Medical application 5

1.6 On receipt 5

1.7 Scope of delivery, accessories and spare parts 6

1.8 Technical data: ERGO 300 – Morcellator 7

1.9 Ambient conditions 7

1.10 Warranty 7

1.11 Technical changes reserved 7

2 Explanation of symbols 8

3 Safety information 9

3.1 EMC, Manufacturer’s Declaration of Conformity 9

3.2 Modification and misuse 9

3.3 In the event of a serious incident 9

3.4 Essential requirements 10

3.5 During use 10

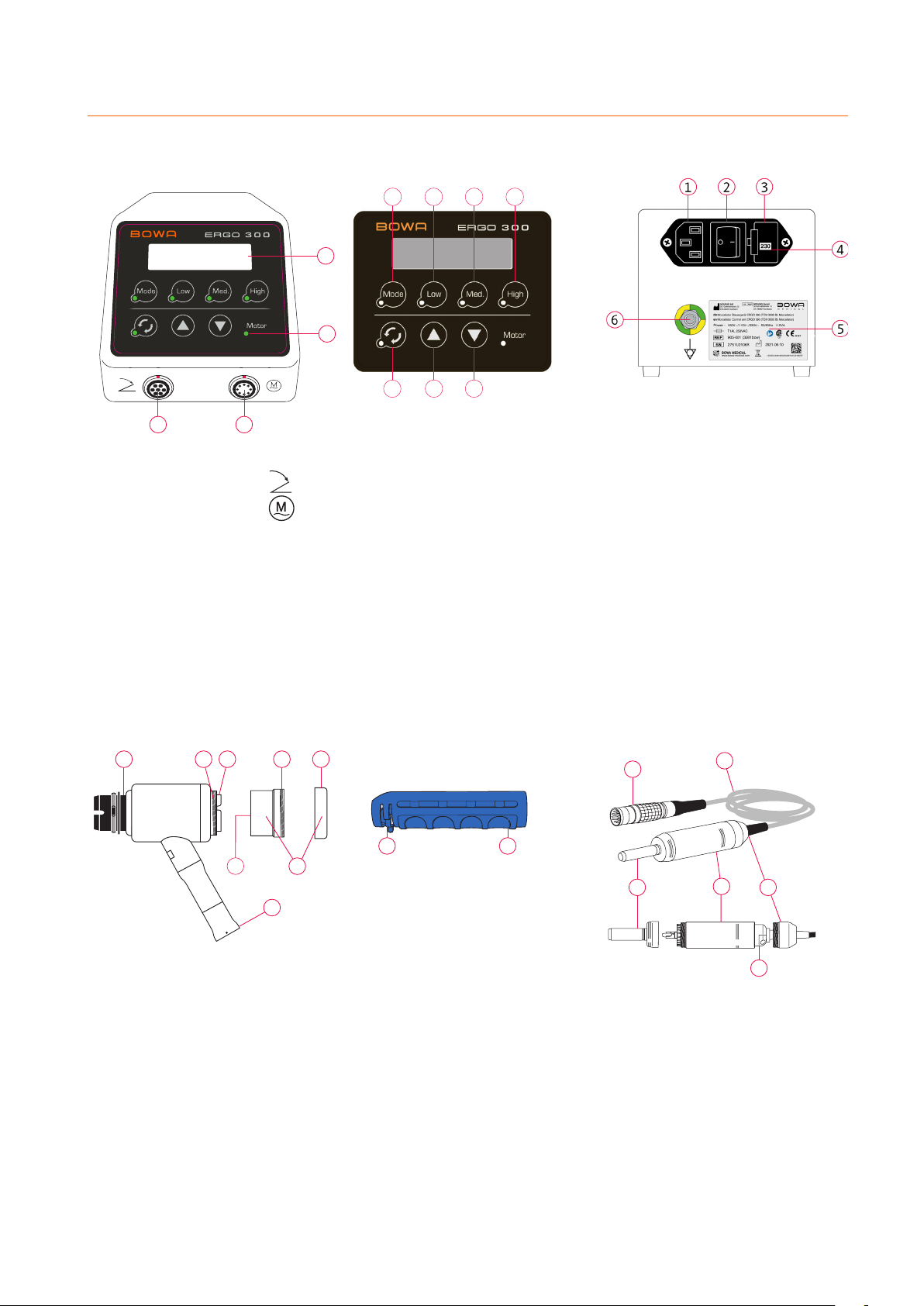

4 Device overview 11

4.1 System-Chart, ERGO 300 – Morcellator 13

5 Before use 14

5.1 Potential equalization connection according to DIN 42801 14

5.2 Connection to the power supply 14

5.3 Device preparation 14

5.3.1 Mounting the morcellator set with protective tube (according to option 1) 15

5.3.2 Assembly of the Morcellator set with Trocar Cannula (according to option 2) 18

5.3.3 Mounting a grasping forceps (according to option 3) 21

5.4 Mains connection 21

6 Operation 22

6.1 Using the control unit 22

6.2 Execution 24

6.2.1 Option 1: Morcellation with protective tube 26

6.2.2 Option 2: Morcellation with Trocar Cannula 27

6.2.3 Option 3: Myomektomy 29

6.3 After use 30

6.4 Disassembly of the Trocar Cannula 31

6.5 Disassembly of the motor 32

6.6 Disassembly of gear unit and Morcellator with protective tube 32

7 Instrument preparation 33

7.1 Control unit and pedal 33

7.2 The following instruments must be reprocessed 34

8 Maintenance and repair 38

8.1 General maintenance 38

8.2 Replacing the control unit fuse 39

8.3 Safety inspections 39

8.4 Malfunction and troubleshooting 40

8.5 Fault messages on the display 41

8.6 Spare parts list with order number 42

8.7 Information on disposal 42

Appendix 43

Electromagnetic Compatibility (EMC) 44

Declaration of Conformity 47

Manufacturer and service points 49

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

1General information

1.1 Indications

Morcellator set for morcellation and extraction of tissue and for removing myomas or the uterus during laparoscopic pro-

cedures in gynecology.

1.2 Principle

The ERGO - Morcellator is a control unit for the Nouvag Morcellator for use in morcellation and extraction of tissue

as well as for myoma removal at laparoscopic interventions. A rotating cylindrical tube with a blade at the distal end is

inserted through an abdominal cavity that has been enlarged by an Insufflator. The tissue that is to be removed is guided to

the cutting tube by a gripper, cut off and removed through the tube.

This manual describes three different options for removing tissue by a laparoscopic procedure.

Option 1: Tissue removal by morcellation with protective tube

Instruments (gripper) are inserted through a protective tube sealed by a valve system. The valve can be covered by a thumb

for removing the gripper from the sealed protective tube to prevent gas loss.

Option 2: Tissue removal by morcellation with Trocar Cannula

Instruments (cutter tube, gripper) are inserted through the Trocar Cannula. The Trocar Cannula contains a valve that pre-

vents gas loss when withdrawing the instruments.

Option 3: Tissue removal (myomectomy) with myoma drill through the Trocar Cannula

Insertion of the myoma drill through the Trocar Cannula (Ø mm) with separate access. Removal of tissue by the Morcel-

lator with grasping forceps according to option or .

For a myomectomy only the Trocar Cannula (REF nou) with a diameter of mm may be used in connection with the

myoma drill.

1.3 Contraindications

Relative or absolute contraindications may result from the general medical findings or in special cases in

which the patient’s risk for motor-driven tools is significantly increased. Ovaries, fallopian tubes, myomata

and other structures must be devascularized and dissected before morcellation.

The laparoscopic deployment of morcellators is contraindicated:

• for treatment of malignant tumors

• for treatment of vascularized tissue

• for preparation of tissue

• in gynecologic surgery in which tissue to be morcellated is known or suspected to contain malignacy

• for removal of uterine tissue containing fibroids in patients who are:

• Peri or postmenopausal, or

• Candidates for en bloc tissue removal, for example through the vagina or via a mini-laparotomy incision.

• Cases described in the literature, must be observed.

1.4 Target group

Younger women between and years of age. From the age of , the risk is increased, but an operation by morcellation

is still possible.

1

8

9

10

7

5

4

3

2

11

12

6

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

1.5 Medical application

This product is designed solely for use in medical facilities by medically qualified persons.

1.6 On receipt

• The shipping package must contain all parts listed in chapter “. Scope of delivery”.

• If any parts are damaged or missing, contact the Nouvag agent from which the device was ordered or

Nouvag AG.

Immediate inspection of the ERGO 300 - Morcellator - motor system set (REF 3287bow):

. Control unit (-)

. Power cable, country-specific

. Gear unit (-)

. Seal unit (bow)

. roof shaped seals (-)

. membrane seals for all cutting tube diameters

(-)

. Electronic motor (-)

. fuses ()

. Vario pedal (-)

. Threaded spray adapter (-) for NouvaOil

spray for the care of the electronic motor

. Handle (-)

. Printed IFU ()

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

1.7 Scope of delivery, accessories and spare parts

REF Description Quantity

905-000 ERGO 300 – Morcellator set comprises the following products...........................................................................1

- ERGO Morcellator control unit, device connecting cable m, country specific......................................................

- Vario pedal; IPX; connecting cable m .....................................................................................................................................

- Electronic motor , m motor cable ..........................................................................................................................................

- Morcellator gear unit .......................................................................................................................................................................

- Handle, complete..............................................................................................................................................................................

bow Information for use (IFU)................................................................................................................................................................

- Threaded adapter for NouvaOil-Spray (REF ) for the care of the electronic motor ............................................

Accessories and spare parts according to option 1:

- Protective tube, Ø mm ...............................................................................................................................................................

- Cutting tube, Ø mm.....................................................................................................................................................................

- Obturator, Ø mm..........................................................................................................................................................................

- Protective tube, Ø mm................................................................................................................................................................

- Cutting tube, Ø mm.....................................................................................................................................................................

- Obturator, Ø mm..........................................................................................................................................................................

bow Replacement sealing unit (small) for cutting tube Ø / mm, incl. membrane seal and roof shaped seal.........

- Set of roof seals (transparent) for cutting tube Ø / mm..........................................................................................

- Set of membrane seals (blue) for cutting tube Ø // mm....................................................................................

Accessories and spare parts according to option 2:

bow Trocar Cannula for Ø mm instruments...................................................................................................................................

bow Trocar Cannula for Ø mm instruments ...................................................................................................................................

bow Seals for Trocar Cannula...............................................................................................................................................................

bow O-ring for Trocar Cannula............................................................................................................................................................

bow Sealing adapter for mounting the small sealing unit on the Trocar Cannula .....................................................................

bow Replacement sealing unit (small) for cutting tube Ø / mm, incl. membrane seal and roof seal .......................

Accessories and spare parts according to option 3:

- Trocar Cannula for Ø mm instruments for myoma drills with Ø mm ........................................................................

bow Sealing adapter for mounting the small sealing unit on the Trocar Cannula .....................................................................

bow Replacement sealing unit (small) for cutting tube Ø / mm, incl. membrane seal and roof seal .......................

In line with regulations pertaining to hazardous materials, the item NouvaClean spray (REF ) and NouvaOil spray

(REF ) is not delivered with the control unit but can be ordered separately from any official Nouvag service center.

www.nouvag.com

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

1.8 Technical data: ERGO 300 - Morcellator

Voltage variable: ...................................................................................................................................... V~/ V~/ V~, / Hz

Fuses, power supply ................................................................................................................................................... fuses T AL, V AC

Power consumption .................................................................................................................................................................................... VA

Maximum motor speed................................................................................................................................................................... , rpm

Maximum motor torque ............................................................................................................................................................................ Ncm

Maximum torque at transmission outlet....................................................................................................................................... Ncm **

Motor coupling ........................................................................................................................................................INTRA-coupling, ISO

Motor cable length ........................................................................................................................................................................................... m

Pedal cable length............................................................................................................................................................................................. m

Morcellator speed range............................................................................................................................................................ – rpm

Type of applied part.............................................................................................................................................................................. Type BF *

Protection class............................................................................................................................................................................................ Class I

Pedal ...................................................................................................................................................................................................................IPX

Dimensions (W x D x H) .................................................................................................................................................... x x mm

Net weight of control unit ........................................................................................................................................................................... kg

* Applied part is the Morcellator

** Maximum torque is delivered at the speed range of 200 - 400 rpm.

1.9 Ambient conditions

Transport and storage: Operation:

Relative humidity: Max.

Temperature: – °C ( – °F) – °C ( – °F)

Atmospheric pressure: – hPa – hPa

1.10 Warranty

Purchasing the ERGO - Morcellator entitles you to a -year warranty. If you return the warranty card for registration

within four weeks of the date of purchase, warranty coverage will be extended for a further months. Improper use or

repair, or failure to observe these instructions, will relieve us from any obligation arising from warranty provisions or other

claims.

1.11 Technical changes reserved

Through further developments, illustrations, dimensions, weights and technical data may differ slightly. Changes and literal

errors reserved.

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

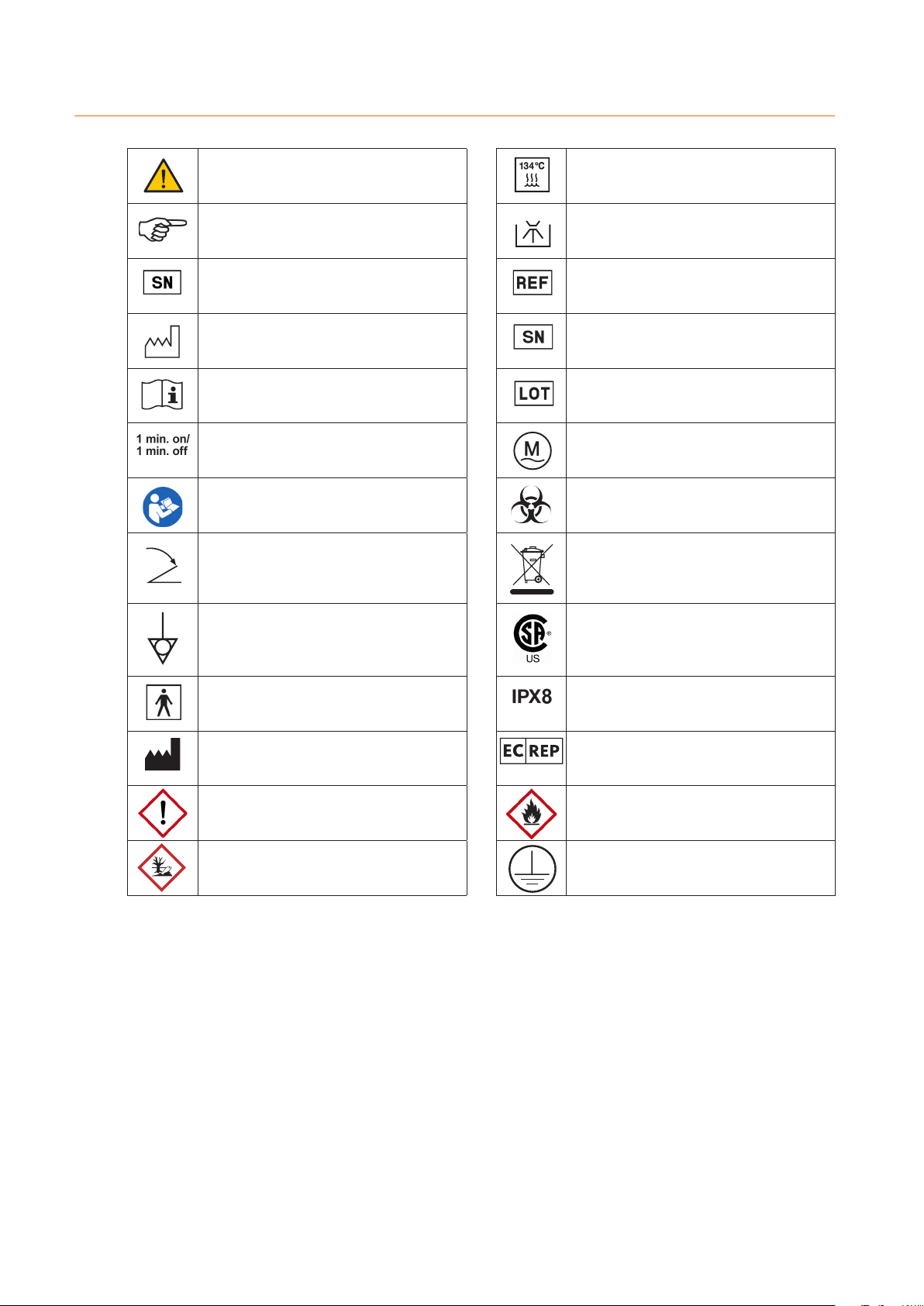

2Explanation of symbols

Warning Autoclavable at °C

Note Suitable for thermal disinfection

Manufacturer Symbol indicating the order number

Date of manufacturing Symbol indicating the serial number

Pay attention to the accompanying documents Symbol indicating the LOT-number

Intermittent operation: 1 min. ON / 1 min. OFF for

8 cycles, brake of 15 min.

Symbol for the motor connection socket

Refer to operating instructions Biohazard

Pedal Disused electrical and electronic equipment

is hazardous waste and must not be disposed

of with household waste. The local disposal

regulations apply.

Potential equalization connection Certified by the Canadian Standards Association

(CSA).regulations apply.

Applied part of type BF is the Morcellator Protected against continuous submersion in

water.

Manufacturer European authorized representative

Dangerous goods aerosol sprays:

Warning!

NouvaClean/NouvaOil

Dangerous goods aerosol sprays:

Extremely flamable

NouvaClean/NouvaOil

Dangerous goods aerosol spray:

Environmentally hazardous

NouvaClean/NouvaOil

Protective ground

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

3Safety information

Your safety, the safety of your team, and of course that of your patients is very important to us. It is therefore essential to

bear the following information in mind:

Every use of the ERGO - Morcellator different to the product description defined in chapter “Intended use and oper-

ation”, causes risks for patients and trained personnel. If physical examinations and therapies are carried out without use

of the devices then the devices must be removed from the place of treatment. Avoid any connection or close adjacency to

other devices.

3.1 EMC, Manufacturer’s Declaration of Conformity

The use of (RF) Radio Frequency emitting devices and equipment as well as the occurrence of negative environmental

factors in the close area of the ERGO - Morcellator may cause unexpected or adverse operation. The connection or the

placing of other devices in close vicinity is not allowed.

The EMISSIONS characteristics of this equipment make it suitable for use in industrial areas and hospitals (CISPR class

A). If it is used in a residential environment (for which CISPR class B is normally required) this equipment might not offer

adequate protection to radio-frequency communication services. The user might need to take mitigation measures, such as

relocating or re-orienting the equipment.

Use only accessories and cables as specified in the product description. Further observe the EMC manufacturers declara-

tion of conformity.

3.2 Modification and misuse

• Modification or manipulation of the ERGO - Morcellator and its accessories is prohibited. The manufacturer is not

liable for any damages resulting from unauthorized modifications or manipulations. The warranty will be canceled.

• Use of the ERGO - Morcellator outside the indications described in Section . is prohibited.

The user or operator is solely responsible for any such use.

3.3 In the event of a serious incident

Any serious incident or problem with the device must be reported to the device manufacturer immediately. An electronic

mail is an advantage and a corresponding form is essential, provided this has already been created.

‚

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

3.4 Essential requirements

Before using the ERGO 300 - Morcellator, this

instruction manual must be read thoroughly and

you must be well acquainted with the functions

and handling of the unit.

The products described in this manual must be

used by trained and qualified medical personnel

only in accordance with the requirements and

with reference to the manual.

For protection of the patient, the user and third

parties the products used must be prepared as

specified in the manual.

Improper use or repair of the device, or failure to

observe these instructions, will relieve us from

any obligation arising from warranty provisions or

other claims.

The use of third-party products is the

responsibility of the operator. Functionality and

patient safety cannot be guaranteed with third-

party accessories.

Prior to using the device, before startup,

and before operation, the user must always

ensure that the device and accessories are in

good working order and are clean, sterile and

operational.

Repairs may only be performed by authorized

NOUVAG service technicians.

Only use NouvaClean and NouvaOil spray to

care for the gear unit. For the electronic motor

use only NouvaOil spray. The use of other care

products can lead to malfunctions and void the

guarantee.

Uterine tissue may contain unsuspected cancerous tissue. The use of laparoscopic, motor-driven morcellators in

hysterectomy and myomectomy, carries the risk of spreading cancerous tissue beyond the uterus, thereby reducing long-

term patient survival. This information should be communicated to patients in advance of surgery when the use of motor-

driven morcellators is being considered.

3.5 During use

The device is not sterile on delivery. All sterilizable

parts must be sterilized before use (see Chapter

Instrument preparation).

Never operate the clamping mechanisms of the

cutting tubes while the system is running. This

could result in instrument damage.

Operate the device only outside the danger zone

of explosive, flammable mixtures or gases.

Keep hands clear of the cutting tubes when

operating the device. Danger of serious injury.

The motor ventilation slots must be kept clear in

order to prevent the motor from overheating.

The ERGO - Morcellator must be operated

under the continuous supervision of medically

qualified persons only.

The risks and benefits of using recovery pouches

when using motor-driven morcellators in

laparoscopic procedures remain to be determined

and established.

Make sure that the operating voltage matches the

mains voltage.

Disregarding the guidelines on intermittent

operation ( min on, min o for 8 cycles) may

cause burns at contact with the gear unit.

2

13

4

56

8

7

21

2

1

3

4

5

6

3 4

2

1

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

4Device overview

Front view Control panel Rear view

Gear unit Handle Motor

. Display

. Motor LED

. Pedal connection

. Motor connection

. Flange for protective tube con-

nection

. Thread for seal holder

. Cutting tube holder

. Seal unit with membrane screw

. Thread for membrane screw

. Membrane screw

. Seal unit thread

. Motor connection coupling

. Key «Vario» (variable speed range)

. Key «Low» (low speed range)

. Key «Medium» (medium speed range)

. Key «High» (high speed range)

. Key «changing rotation direction»

(When changing the direction of rotation,

the device emits a tone signal.)

. Key «UP» (increase value)

. Key «DOWN» (reduce value)

. Release lever

. Handle

. Mains connection

. Power switch ON/OFF

. Fuse compartment

. Window with indication of

national voltage

. Type plate with type designation,

reference number, serial number,

information on power supply and

device fuse

. Potential equalization

. Device connection plug

. Motor cable

. Motor cap

. Motor

. Handpiece holder

. Motor connection plug

3

1 2

4

1

2

3

4

5

12

1

23

45

7

6

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

Protection sleeve with Obturator

Cutting tube

Trokar sleeve

Grasping forceps

. Protecting sleeve

. Seal unit and Morcellator

attachment

. Valve actuation

. Valve body

. Main body

. Nose for tissue protection

. Cutting edge

. Locking pins

. Protection sleeve

. Locking nut

. Nose for tissue protection

. Obturator

. Mouth insert

. Gripper mouth

. Tube shaft

. Fixed leg

. Flexible leg

. Locking device

. Spring component

Handle

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

4.1 System-Chart, ERGO 300 – Morcellator

Option 1

Option 2

Option 3

Grasping forceps

Grasping forceps

Gear unit

Gear unit

Seal adapter

Seal adapter

Handle

Handle

Myoma drill

Protection sleeve with Ø 12/15 or 20 mm

Protection sleeve with Ø 12 or 15 mm

Protection sleeve with Ø 12 mm

Obturator with Ø 12 or 15 mm

Obturator with Ø 12 or 15 mm

Cutting tube with Ø 12 or 15 mm

Cutting tube with Ø 12 or 15 mm

Cutting tube with Ø 20 mm

Small sealing unit for Ø 12/15 mm

Small sealing unit for Ø 12/15 mm

Small sealing unit for Ø 12/15 mm

Small sealing unit for Ø 12 to 15 mm

Obturator with Ø 20 mm

Large sealing unit Ø 20 mm

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

5 Before use

The ERGO – Morcellator and all required accessories and instruments must be placed on a level nonslip surface. Do

not allow the operating range of the device with cable to be restricted by limiting factors. The display, keypad and indicator

lights must be fully visible at all times.

It is very important to ensure that no objects can fall on the pedal. The power plug at the rear of the device must be acces-

sible at all times.

5.1 Potential equalization connection according to DIN 42801

At the back of the device a potential equalization plug is installed, according to DIN .

The additional potential equalization has the task of equalizing potentials between different parts of conduc-tive materials

that can be touched at the same time, or reducing potential differences.

This connection must be used, to protect the patient, the user and third parties from touch voltages.

The equipotential plug is marked with the following symbol:

5.2 Connection to the power supply

• Before plugging the power cable into the power socket for the first time, you must check the supply voltage setting

next to the power switch.

• In order to prevent the risk of electric shock, the device may only be connected to a power network with a

PE protective earth conductor.

If the voltage shown does not correspond to the local mains voltage, the grey fuse holder must be set to the correct voltage:

. Switch the device off.

. Unplug the power cable.

. Use a screwdriver to open the fuse slot.

. Remove the fuse holder.

. Remove the grey fuse holder and reinsert it so that the local mains voltage setting is shown in the small window.

. Slide the grey fuse holder back in and close the fuse slot.

. Check the mains voltage shown on the fuse slot.

. Plug the power cable back into the device.

5.3 Device preparation

The device is not sterile on delivery. All sterilizable parts must be sterilized before use (see Chapter Instrument prepara-

tion).

If the accessories have already been sterilized: when removing them from the sterile packaging, ensure that the sterile

packaging is not damaged and that the sterility indicator confirms sterility and shelf life of the sterile item has not ex-

pired.

The Morcellator (as per option 1 to option 3) must be assembled under sterile conditions (wear gloves and a mask, place

Morcellator and accessories on a sterile surface).

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

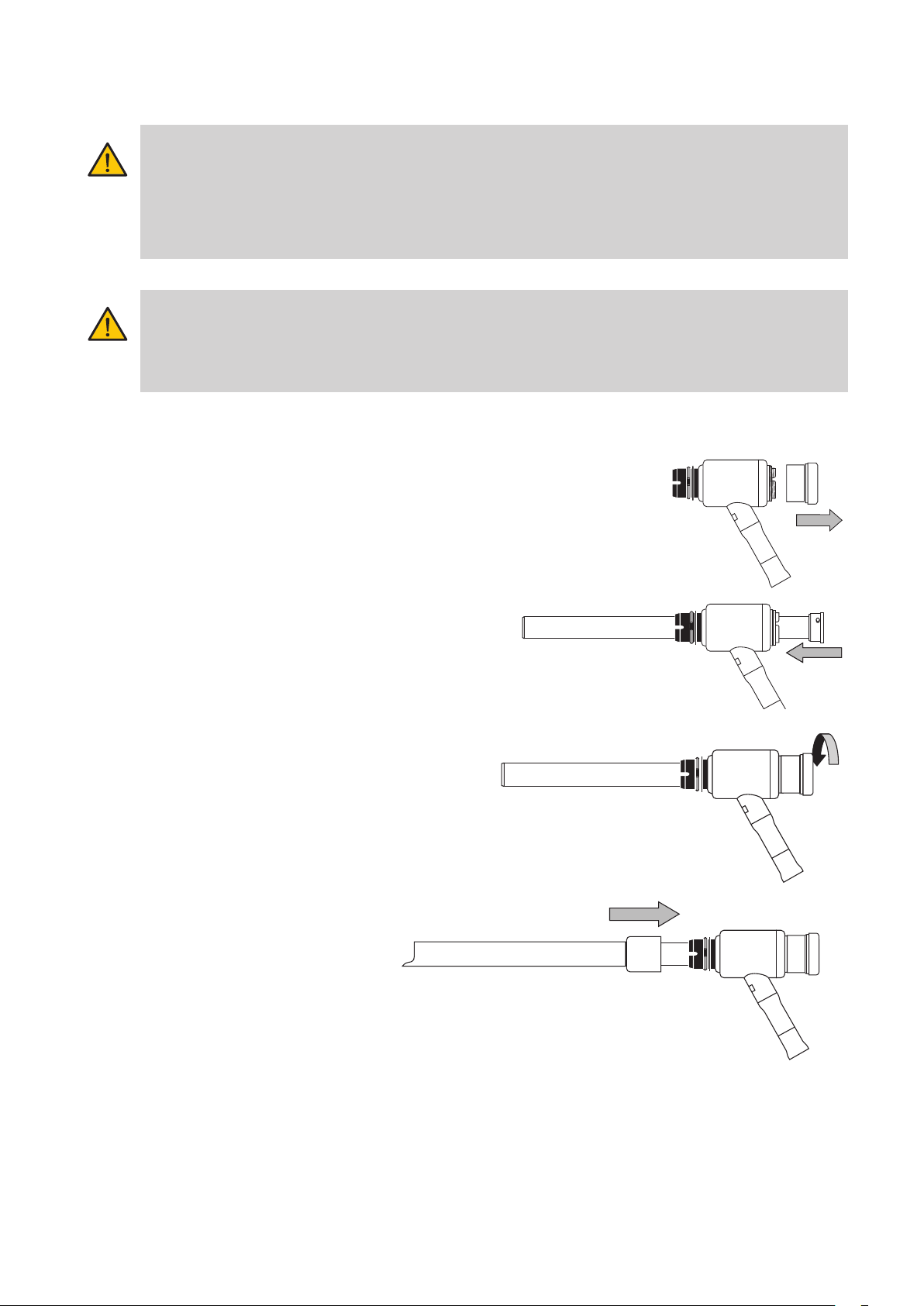

5.3.1 Mounting the morcellator set with protective tube (according to option 1)

There is a risk of injury to tissue by the sharp edge at the distal end of the cutting tube.

• Handle the cutting tube carefully.

• If the cutting tube is not used, rotate the protective tube to the NO CUT position.

• If the cutting tube is not used, it must be placed on a flat, sterile surface so it cannot fall and cause injury

• Check the cutting tube.

• Make sure that the cutting edge of the blade is sharp and undamaged (e.g. no cracks, deformation or burrs).

• Use only cutting tubes in perfect condition.

1. Inserting the cutting tube through the gear unit

Remove the seal unit from the gear unit.

Insert the cutting tube through the gear unit. The two

guide pins on the cutting tube must fit into the slot on

the flange of the gear unit.

2. Fixing the cutting tube to the gear unit

Hold the cutting tube with one hand.

Connect the sealing unit to the gear unit with the

bayo-net closure with the other hand.

3. Mounting protective tube

Select a suitable protective tube.

Push the protective tube over the distal end of the cutting

tube. The guide pin of the protective tube must be in the

distal slot of the gear unit.

Lock the protective tube in position with a click.

NO CUT

3

2

14

5

6

6

3

3

2

14

5

6

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

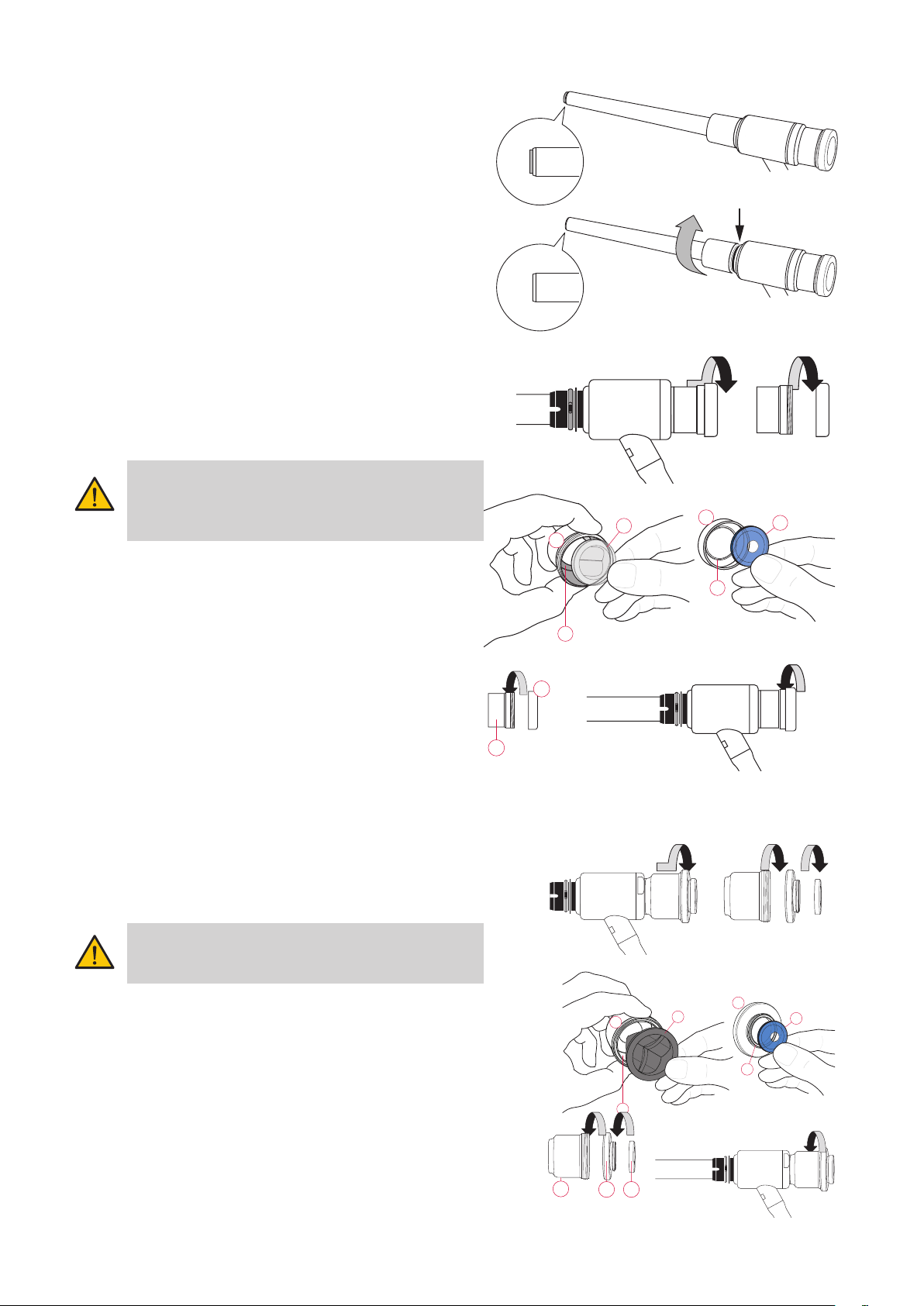

4. Protecting the cutting tube

The distal end of the cutting tube is very sharp.

To prevent injury, the cutting tube must be covered at all

times when it is not in use.

To cover the cutting tube, rotate the protective tube until

the words “NO CUT” are visible in the distal slot of the

gear unit.

The cutting tube is completely covered by the protective

tube.

5a.Replacing the seals of the small sealing unit to use Ø

12/15 mm cutting tubes

Remove the seal unit from the gear unit.

Unscrew the membrane screw from the seal unit.

Check seals before use. Do not use damaged seals (frayed,

discolored, yellowed, porous, no longer elastic).

Position the edge of the roof shaped seal () to point to

the inside stop () of the seal holder () and press the roof

shaped seal in.

Position the edge of the membrane seal () to point to the

slot () of the membrane screw () and press the mem-

brane seal into the slot.

Screw the membrane screw () into the thread of the seal

holder () to the stop and connect the seal unit to the

gear unit.

5b.Replacing the seals of the large sealing unit, for the use of

Ø 20 mm cutting tubes

Unscrew the large sealing unit from the gear unit. Unscrew the

membrane fixing ring from the roof shaped seal fixing ring. Un-

screw the roof shaped seal fixing ring from the seal holder.

Check seals before use. Do not use damaged seals (frayed,

discolored, yellowed, porous, no longer elastic).

Position the edge of the roof shaped seal () to point to the inside

stop () of the seal holder () and press the roof shaped seal in.

Position the edge of the membrane seal () to point to the slot ()

of the membrane screw () and press the membrane seal into the

slot.

Screw the roof-shaped seal fixing ring () all the way onto the

thread of the seal holder () and screw the membrane fixing ring

() onto the roof-shaped seal fixing ring (). Now screw the entire

sealing unit () onto the gear unit ().

2

1

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

6. Inserting the Obturator

Insert the Obturator through the seal unit, gear unit and

protective tube to the stop.

7. Attaching the handle

Lift and hold the release lever () of the handle ().

Push the handle () over the motor connection of the gear

unit.

Release the handle release lever. The handle release lever

must lock in position.

Do not open the handle release lever to remove the handle during the procedure.

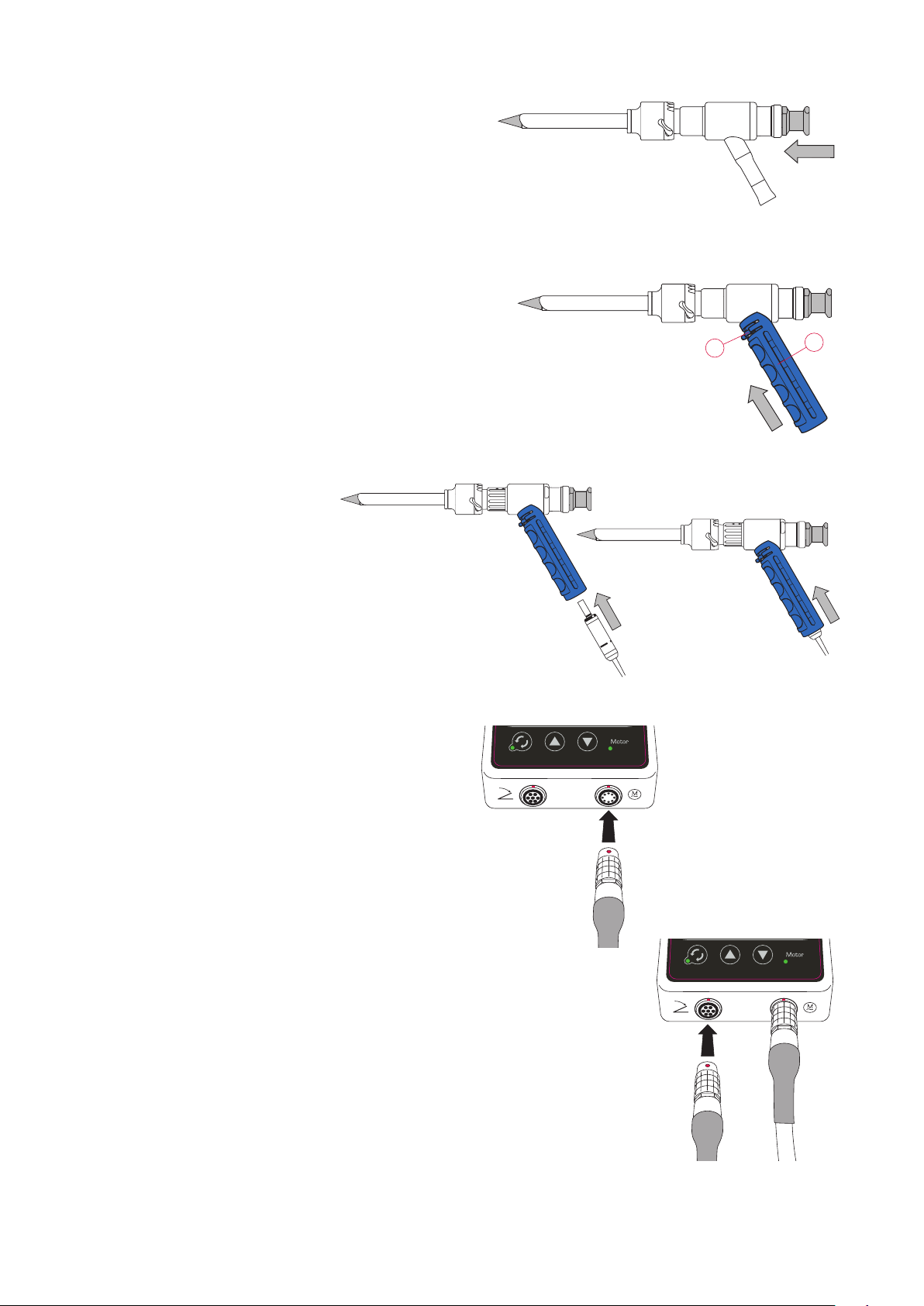

8. Connecting the motor

Insert the motor coupling into the bottom end of the

handle.

Continue to insert the motor until it locks into the gear

unit’s motor connection.

Align the red dot on the device connection plug of the

motor with the red dot on the motor connection of the

control unit.

Plug the motor device connection plug into the motor

connection of the control unit. The plug must lock in

position.

9. Connecting pedal

Align the red dot on the device connection plug of the

pedal with the red dot on the pedal connection of the

control unit.

Plug the pedal device connection plug into the pedal

connection of the control unit.

The plug must lock in position.

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

Functional check

• Check Morcellator for loose parts

• Check that Morcellator is correctly assembled

• Are all labels easily readable?

• Check cutting tube: cutting tube evenly ground, no broken edges or bends?

• Switch on control unit

• Switch on motor (press pedal).

• Run motor with Morcellator for about seconds; it must reach the set speed.

• If it does not run evenly, switch off motor with Morcellator.

• Switch off control unit.

The control unit will only operate if the pedal has been connected to the control unit.

• Check that Morcellator is correctly assembled.

• Check that the gear unit runs smoothly; if necessary treat it with NouvaOil care spray.

• Check that the motor is clean and runs smoothly; if necessary clean it and treat with NouvaOil care spray.

• Repeat the function check.

Risk of injury by motor failure

Problem: the motor becomes very hot. Cause: the motor was damaged during preparation.

Remedy: do not continue to use the motor. Always have a spare motor available.

5.3.2 Assembly of the Morcellator set with Trocar Cannula (according to option 2)

Using the Trocar Cannula

The Trocar Cannula is used instead of the protective tube. The integrated valve flap prevents the escape of gas when

instruments are moved in and out.

The nose of the Trocar Cannula partially extends beyond the cutter tube to protect organs in the abdominal cavity from

the sharp blade. This requires the Morcellator to be rotated under visual supervision (endoscopy) so the nose of the Tro-

car Cannula covers the cutter tube blade to protect the organ.

1. Visual check

• Check the product for sealing, corrosion and sterility.

• Ensure that it is free from rust, dents and scratches.

• The distal end of the Obturator must not be damaged.

• The sealing flap and the seal must not be damaged.

Risk of injury

Select blade. Make sure that the cutting edge of the blade is sharp and undamaged (e.g. no cracks or burrs).

3

2

14

5

6

6

3

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

2. Insert the cutting tube through the gear unit

Remove the seal unit from the gear unit.

Insert the cutting tube through the gear unit. The two

guide pins on the cutting tube must fit into the slot on

the flange of the gear unit.

3. Fixing the cutting tube to the gear unit

Hold the cutting tube with one hand.

With the other hand screw the seal unit onto the gear

unit.

4. Mounting Trocar Cannula

Select a suitable Trocar Cannula. Open the Trocar Cannula

valve by actuating the lever to prevent damage to the

cutting tube by pushing the Trocar too far.

Push the Trocar Cannula over the distal end of the cutting

tube. The guide pin of the Trocar Cannula must be in the

distal slot of the gear unit.

Lock the Trocar Cannula in position with a click.

5. Replacing seals

Remove the seal unit from the gear unit by rotating it

slightly.

Unscrew the membrane screw from the seal unit.

Keep each a roof shaped seal (transparent) and a mem-

brane seal (blue) ready.

6. Position the edge of the roof shaped seal () to point to the

inside contact () of the seal holder () and press the roof

shaped seal in.

Position the edge of the membrane seal () to point to the

slot () of the membrane screw () and press the mem-

brane seal into the slot.

7. Screw the membrane screw () into the thread of the seal

holder () to the stop and connect the seal unit to the gear

unit.

2

1

Instructions for use, ERGO - BOWA- IFU-- ERG-S-EN-

8. Inserting Obturator

Insert the Obturator through the seal unit, gear unit and

Trocar Cannula.

9. Attaching handle

Lift and hold the release lever () of the handle ().

Push the handle () over the motor connection of the gear unit.

Release the handle release lever. The handle release lever must lock in position.

10.Connecting motor

Insert the motor coupling into the bottom end of the

handle.

Continue to insert the motor coupling until it locks into

the gear unit motor connection.

Align the red dot on the device connection plug of the

motor with the red dot on the motor connection of the

control unit.

Plug the motor device connection plug into the motor

connection of the control unit. The plug must lock in

position.

11. Connecting the pedal

Align the red dot on the device connection plug of the

pedal with the red dot on the pedal connection of the

control unit.

Plug the pedal device connection plug into the pedal con-

nection of the control unit. The plug must lock in position.

Other manuals for ERGO 300

1

Table of contents

Other Bowa Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual