3

Safe handling and preparation

CAUTION

Federal law restricts this device to sale by, or on

order of a physician!

Note

A specially designed Aesculap endoscope is offered for

the MINOP InVent trocar system. For reasons of com-

patibility, the MINOP InVent trocars may only be used

with this special Aesculap endoscope.

►Ensure that the product and its accessories are

operated and used only by persons with the requi-

site training, knowledge, or experience.

►Read, follow, and keep the instructions for use.

►Use the product only in accordance with its

intended use, see Intended use.

►Remove the transport packaging and clean the new

product, either manually or mechanically, prior to

its initial sterilization.

►Store any new or unused products in a dry, clean,

and safe place.

►Prior to each use, inspect the product for loose,

bent, broken, cracked, worn, or fractured compo-

nents.

►Do not use the product if it is damaged or defec-

tive. Set aside the product if it is damaged.

►Replace any damaged components immediately

with original spare parts.

►Perform a function check of the irrigation channel

before each use.

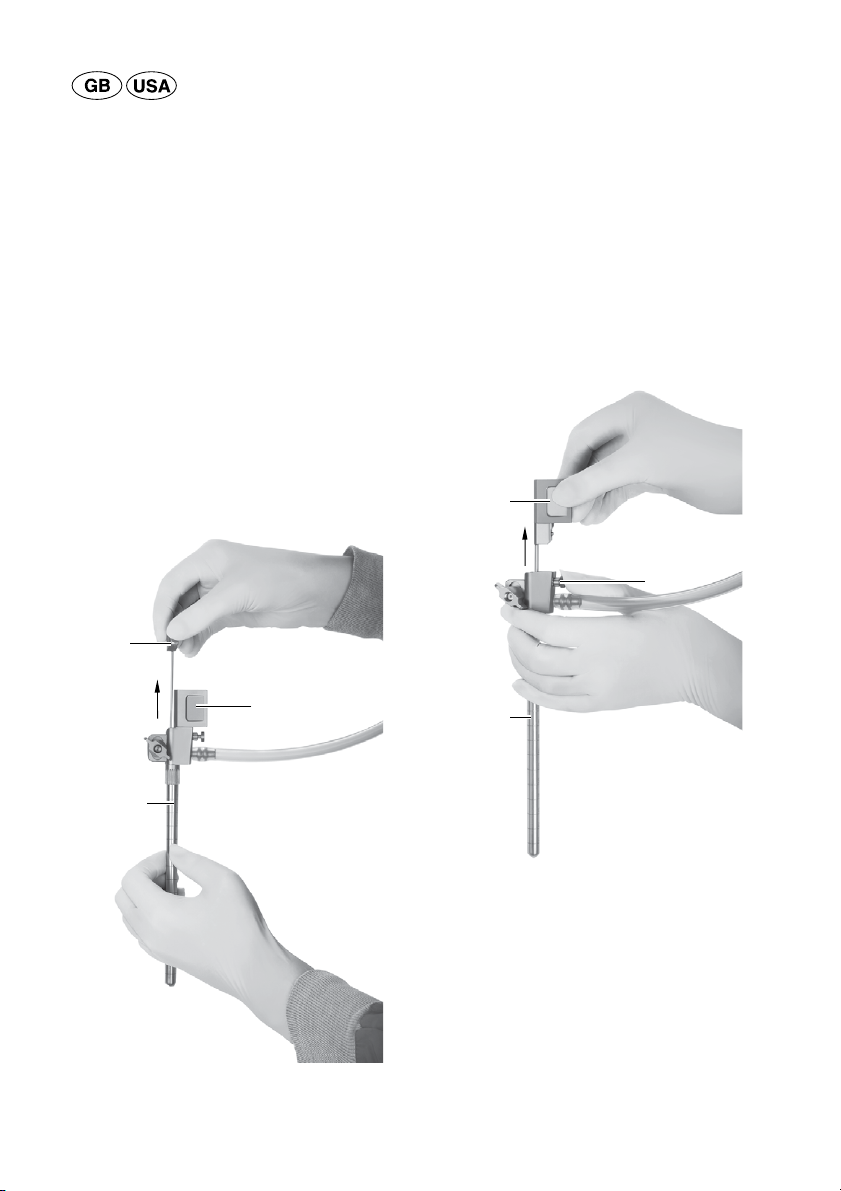

►Perform a function check of the endoscope's stop

mechanism before each use.

►To avoid burns when using the MINOP InVent tro-

car in combination with HF electrodes, ensure that

HF current is activated only under visual control.

►When inserting the trocar into the brain/the ven-

tricle, close the working channel with the obtura-

tor provided.

Safe operation

WARNING

Risk of injury caused by incor-

rect operation of the product!

►Attend appropriate prod-

uct training before using

the product.

►For information about

product training, please

contact your national

B. Braun/Aesculap agency. WARNING

Risk of injury and/or malfunc-

tion!

►Always carry out a func-

tion check prior to using

the product.

WARNING

Risk of injury when using the

product beyond the field of

view!

►Apply the product only

under visual control.

WARNING

Risk of injury caused by pro-

truding 30° endoscope in

locked position!

►Insert the endoscope only

when the trocar is in its

final position.

WARNING

Risk of burns due to high tem-

perature of the instrument-

side end of the optical cable of

a light source!

►Apply proper care when

operating the light source.