3

1 OPERATING INSTRUCTIONS ................................................................4

1.1 Symbols ....................................................................................... 4

1.2 Definition of the term "Device" ............................................... 4

2 AUTHORIZED USE ......................................................................................5

3 BASIC SAFETY INSTRUCTIONS ..........................................................5

4 GENERAL INFORMATION ........................................................................6

4.1 Contact addresses ...................................................................6

4.2 Warranty ...................................................................................... 6

4.3 Information on the Internet ...................................................... 6

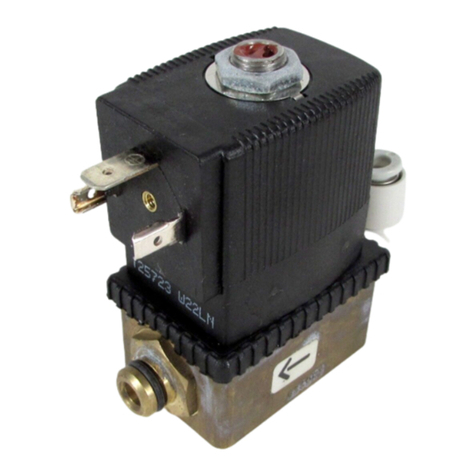

5 PRODUCT DESCRIPTION ........................................................................7

5.1 General description ..................................................................7

5.2 Properties ....................................................................................7

6 STRUCTURE AND FUNCTION...............................................................8

6.1 Structure ...................................................................................... 8

6.2 Function ....................................................................................... 8

7 TECHNICAL DATA .....................................................................................10

7.1 Conformity .................................................................................10

7.2 Standards ..................................................................................10

7.3 Type label ..................................................................................10

7.4 Operating conditions ..............................................................10

7.5 General technical data ...........................................................13

8 ASSEMBLY .................................................................................................... 14

8.1 Safety instructions ...................................................................14

8.2 Before installation ....................................................................14

8.3 Installation .................................................................................15

8.4 Pneumatic connection ............................................................17

9 START-UP ......................................................................................................18

9.1 Control pressure ......................................................................18

9.2 Incoming flow above upper seat

(direction of flow 3 → 2) .........................................................18

9.3 Flow direction below the lower seat

(direction of flow 1 → 2) .........................................................18

10 DISASSEMBLY ............................................................................................ 18

11 MAINTENANCE, TROUBLESHOOTING ......................................... 19

11.1 Safety instructions ...................................................................19

11.2 Maintenance work ...................................................................19

11.3 Malfunctions .............................................................................20

12 SPARE PARTS.............................................................................................21

13 PACKAGING, TRANSPORT, STORAGE .......................................... 22