cod. +050003210 rel. 1.1 - 25.09.2003

PCOUMID200 Scheda per gestione umidificatore OEM per pCO / OEM humidifier control board for pCO

Vi ringraziamo per la scelta fatta, sicuri che sarete soddisfatti del

vostro acquisto.

CARATTERISTICHE GENERALI

Il modulo PCOUMID200 è un'interfaccia dei controllori elettronici pCO. Permette

di controllare i parametri fondamentali degli umidificatori OEM prodotti da

CAREL (alto livello e conducibilità acqua di alimento nel cilindro, sensore TAM di

assorbimento corrente) direttamente dal regolatore elettronico a microprocessore

pCOB/pCO2/pCO1/pCOC.

I valori raccolti dagli appositi sensori vengono convertiti in segnali compatibili

dagli ingressi presenti nel pCO (per maggiori informazioni si rimanda al relativo

manuale utente del programma applicativo).

L’interfaccia PCOUMID200 rispetto all’interfaccia PCOUMID000 si differenzia per:

- maggior precisione e immunità ai disturbi sia per la misura di conducibilità

che per la misura del sensore di livello;

- il segnale di “alto livello acqua” può essere gestito sia con uscita digitale

che analogica.

Risulterà dunque possibile collegare al controllore sia la scheda pCOUMID000

che la scheda pCOUMID200, con l’unica accortezza di dover configurare un

opportuno parametro, in modo da permettere al software di utilizzare la corretta

curva di conducibilità.

CARATTERISTICHE TECNICHE

tensione d’ingresso: 24 Vac ± 15%

potenza assorbita: 3 W (5 VA);

morsettiere - sez. conduttori: min. 0,5 mm2, max. 2,5 mm2

condizioni di funzionamento: -10T60 °C; 90 % U.R. non condensante

condizioni di immagazzinamento: -20T70 °C; 90% U.R. non condensante

grado di inquinamento: normale

dimensioni (mm): 110,8 x 70,4 x 60

grado di protez. fornito dall’involucro: IP20

classificazione secondo la protezione contro le scosse elettriche: Classe II.

Tutte le uscite sono protette da cortocircuito.

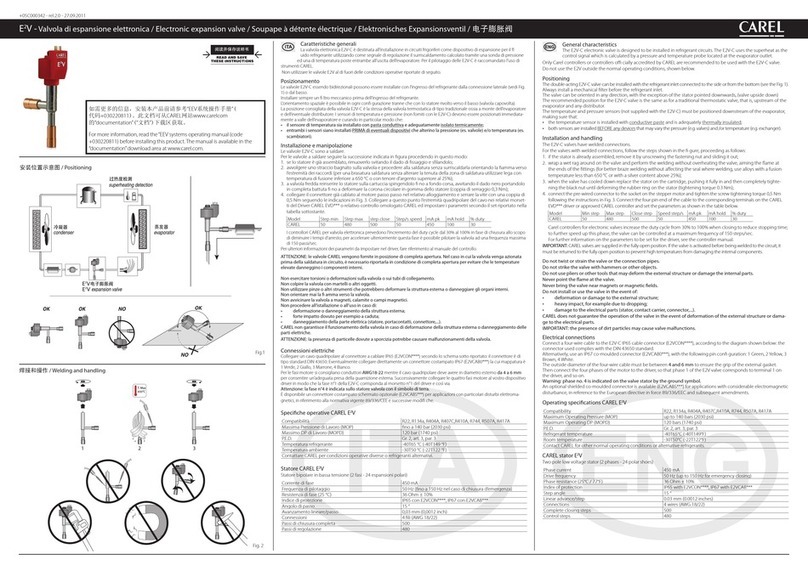

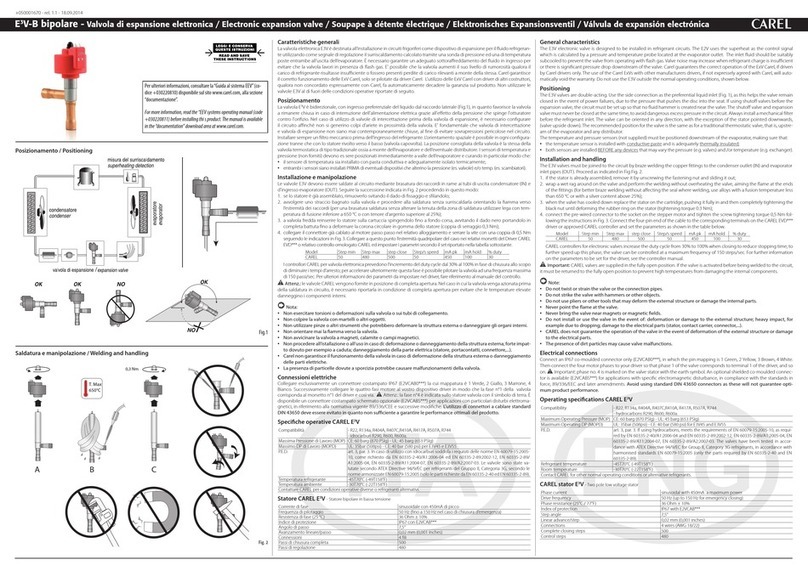

INSTALLAZIONE

Il montaggio previsto è mediante fissaggio su guida omega (guida DIN

standard).

DICHIARAZIONI

• PTI dei materiali usati per l’isolamento: >250 V

• Periodo di sollecitazioni elettriche delle parti isolanti: Lungo

• Categoria di resistenza al calore e al fuoco: D

• Categoria (immunità contro le sovratensioni): 2

Thank you for choosing Carel. We are confident that you will be satisfied

with your purchase.

GENERAL CHARACTERISTICS

The PCOUMID200 module is an interface for the pCO series electronic

controllers. It is used to control the fundamental operating parameters of the

OEM humidifiers manufactured by CAREL (high water level, water conductivity in

the cylinder, and TAM current. sensor) directly from the pCOB/pCO2/pCO1/pCOC

electronic microprocessor controller.

The values read by the special sensors are converted into signals that are

compatible with the inputs on the pCO (for further information, refer to the

corresponding application software user manual).

The PCOUMID200 interface differs from the PCOUMID000 interface in the

following ways:

- greater precision and immunity to disturbances for both the conductivity and

the level sensor;

- the “high water level” signal can be managed either by a digital or analogue

output.

Consequently, both the pCOUMID000 and the pCOUMID200 boards can be

connected to the pCO, with the only requirement being that a special parameter

has to be set to allow the software to use the correct conductivity curve.

TECHNICAL SPECIFICATIONS

power supply: 24Vac ± 15%

power consumption: 3W (5VA);

terminal blocks - wire cross-section: min. 0.5 mm2, max. 2.5 mm2

operating conditions: -10T60°C; 90 % rH non-condensing

storage conditions: -20T70°C; 90% rH non-condensing

pollution: normal

dimensions (mm): 110.8 x 70.4 x 60

case index of protection: IP20

classification according to protection against electric shock: Class II.

All outputs are protected against short-circuits.

INSTALLATION

The device is installed by mounting on a standard DIN rail.

DECLARATIONS

• PTI of the insulation materials: >250V

• Period of electric stress across the insulating parts: Long

• Category of resistance to heat and fire: D

• Category (immunity against voltage surges): 2

Dimensioni 4 moduli DIN / Dimensions: 4 DIN modules