6

3.2 Usage as intended

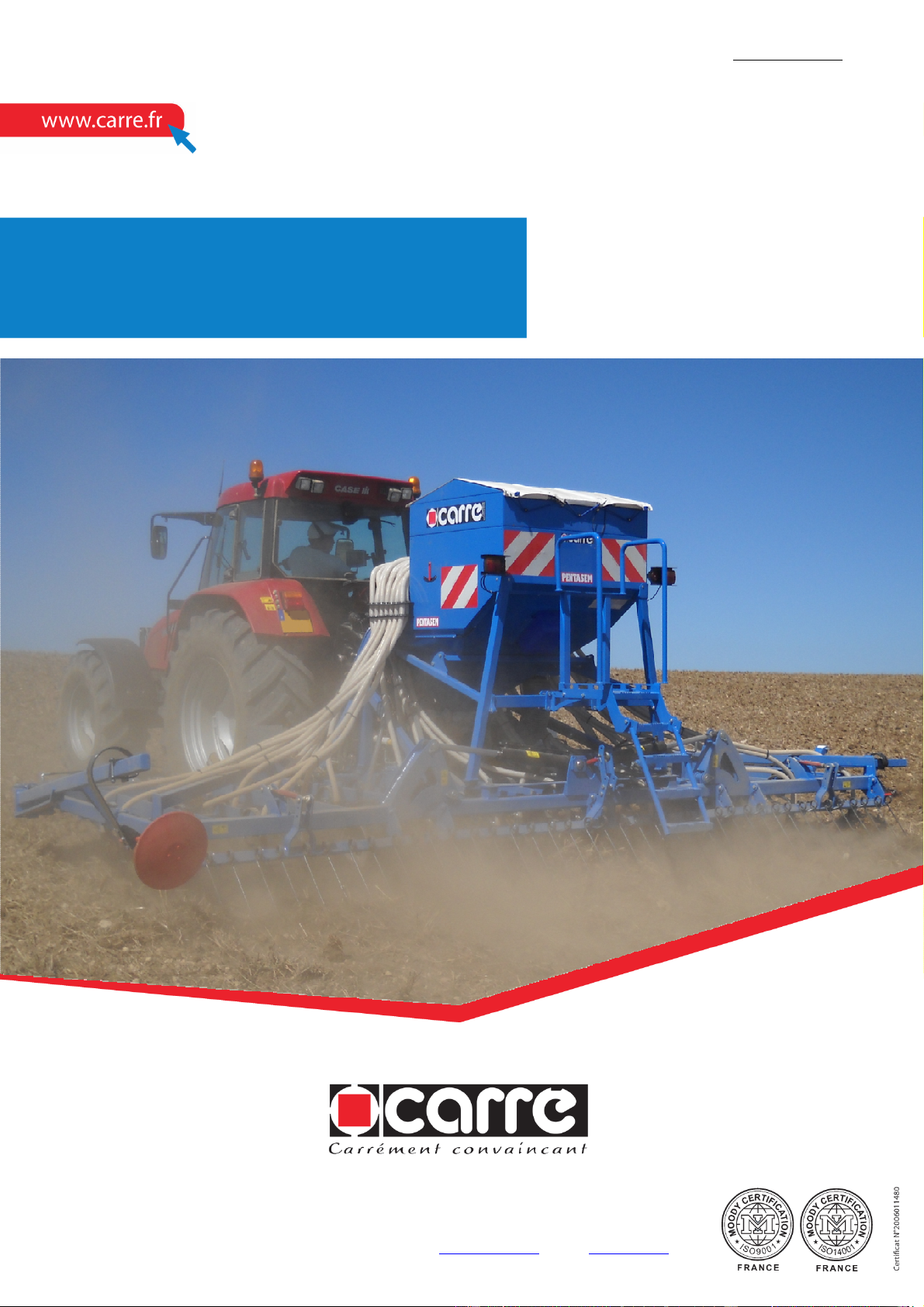

PENTASEM is designed to be used for planting a crop in simplified sowing at high speed.

Any use other than the latter shall be considered as non-compliant with the intended use

and shall release the manufacturer from any liability in the event of prejudice; the user

alone shall incur the risks that result from such use.

Comply with all of the installation, operating, adjusting, maintenance and repair instructions

contained in this notice.

Use only spare parts and accessories that comply with the manufacturer's

recommendations.

The use, maintenance and overhauling of the PENTASEM must be entrusted only to

people who are familiar with and who are informed of the possible dangers.

Do not modify or have your machine and its accessories modified by another person

(mechanical, electrical, hydraulic, pneumatic characteristics), without first obtaining

approval from your manufacturer.

Not complying with these rules can make your machine dangerous. In the event of damage

or injury, the manufacturer shall be released from any liability.

Moreover, the special instructions concerning the prevention of accidents must be complied

with, as well as the general rules in terms of technical safety, occupational medicine and

legislation concerning the use of roads.

The manufacturer declines all liability in the event of prejudice resulting from a modification

made to the PENTASEM without its approval.

3.3 General safety instructions

Only use the PENTASEM if all of the protective and safety devices are installed and are

operating correctly.

Check that the screws are tight on a regular basis and tighten them if necessary, especially

the clamping screws for the tines and the bearings on the equipment.

In the event of operating incidents, stop the machine immediately, then repair the

breakdown or have it repaired immediately.

3.4 Safety in the public domain

Before driving on a road, you must become familiar with the operation of all of the controls.

Comply with the rules of the road when you move into the public domain (roads, paths and

squares). Make sure beforehand that the condition of the PENTASEM is compliant with the

regulations set forth in the rules of the road.

Comply with authorised transport width limitations.

Adjust your speed and driving style to the land, roads and paths. Remain vigilant and

cautious!

At all times and in particular on sloped and broken land, operate the machine at slow

speed, especially when turning and do not change direction abruptly.

Do not brake or start abruptly while going up or down a slope.

Driving is influenced by the machine coupled to the tractor. Comply with the axle load limit

and the gross weight so that steering and braking precision are maintained and, when

turning, give particular attention to the overhang and the inertia mass of the PENTASEM.

Do not transport anyone on the PENTASEM.