5

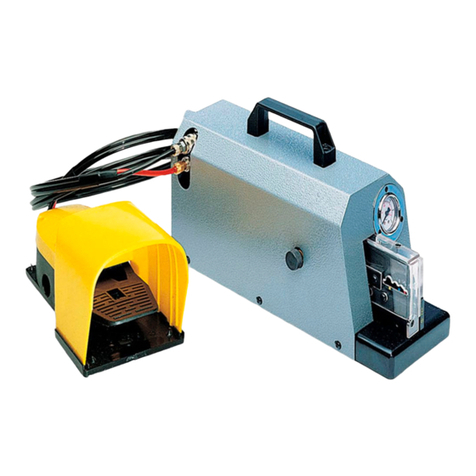

2. INSTRUCTIONS FOR USE

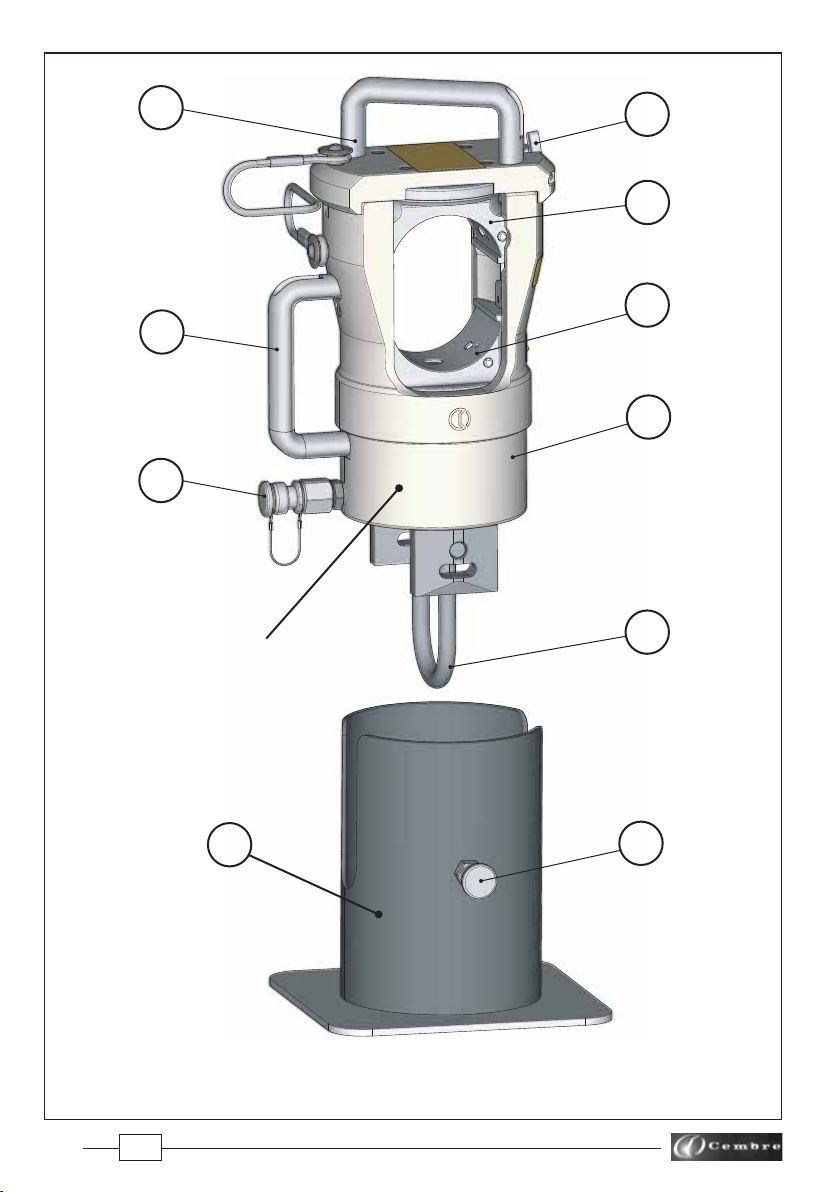

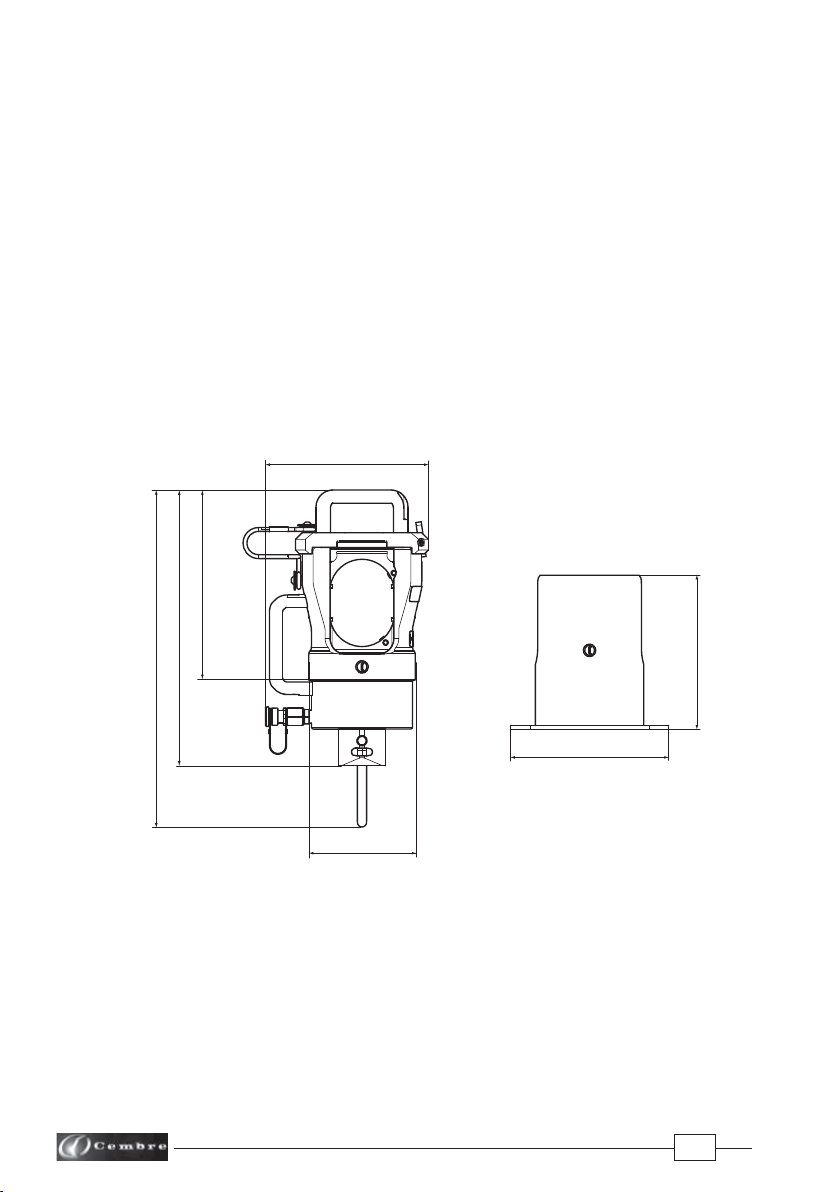

For use on a level and stable surface, e.g the ground, the head should be mounted and locked wih

the knob (4) on the HS600 support base provided.

Alternatively, the head may be suspended for use, via the integral hanger (27), ensuring the sus-

pension method is secure and safe.

2.1) Setting

– Connect the presshead to the pump hose; the head is equipped with a "self-lock" quick male

coupler and can be connected to a Cembre hydraulic pump developing 700 bar (10,000 psi)

pressure.

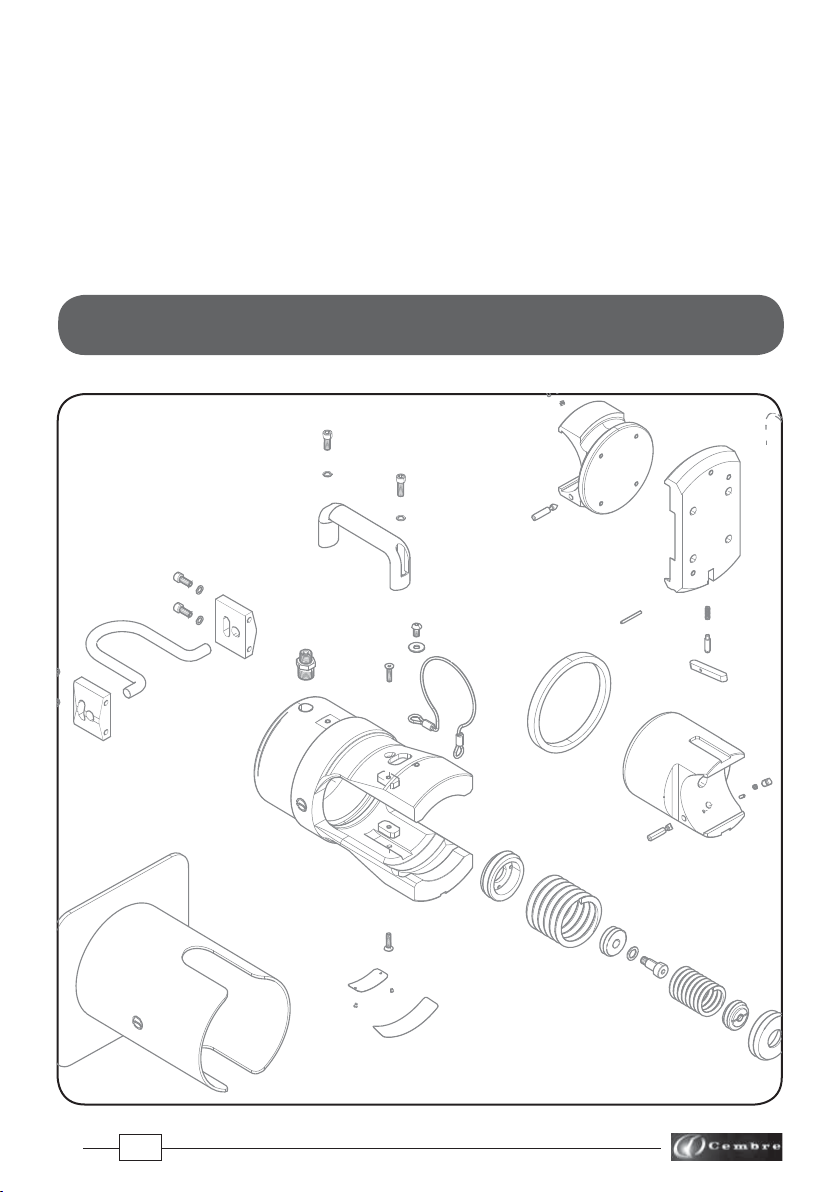

2.2) Die insertion (Ref. to Fig. 3)

Make sure that the top die holder and the latch are correctly located.

BEFORE OPERATING MAKE SURE THE LATCH IS SECURE. LATCH IMPROPERLY SECURED CAN CAUSE

TOOL DAMAGE AND PERSONAL INJURY.

– Select the appropriate die set for the connector.

– Insert the die (90) in the upper seat of the top die holder (201) until it is locked by die/head pin (6).

To ease the die insertion, keep die/head release pin (4) depressed.

– Insert the die (91) into the seat on the ram (202) until it is locked by die/ram retaining pin (6);

To ease this operation, keep die/ram release pin (4) depressed.

NEVER PRESSURIZE THE HEAD WITHOUT THE DIE IN PLACE AS SERIOUS DAMAGE AND/OR PERSONAL

INJURY MAY RESULT.

2.3) Die positioning

– Insert the conductor into the connector (see § 2.6).

– Locate the connector between the dies at the desired crimp position.

– Operate the pump until the dies touch the connector.

Make sure that dies are exactly positioned on desired crimp point, otherwise re-open dies

following instructions as per § 2.5 and position the connector again.

2.4) Crimping

– Operate the pump to advance the ram until the die faces touch.

It is recommended to continue pumping until the maximum pressure valve is activated and a

“click” is heard.

– Re-open dies (see § 2.5) and repeat steps above as necessary.

2.5) Die opening

– Fully discharge the oil pressure from the pump to retract the ram (202) and release the crimped

connector.

CHECK THAT THE RAM IS COMPLETELY RETRACTED BEFORE DISCONNECTING THE HOSE FROM THE

HEAD.