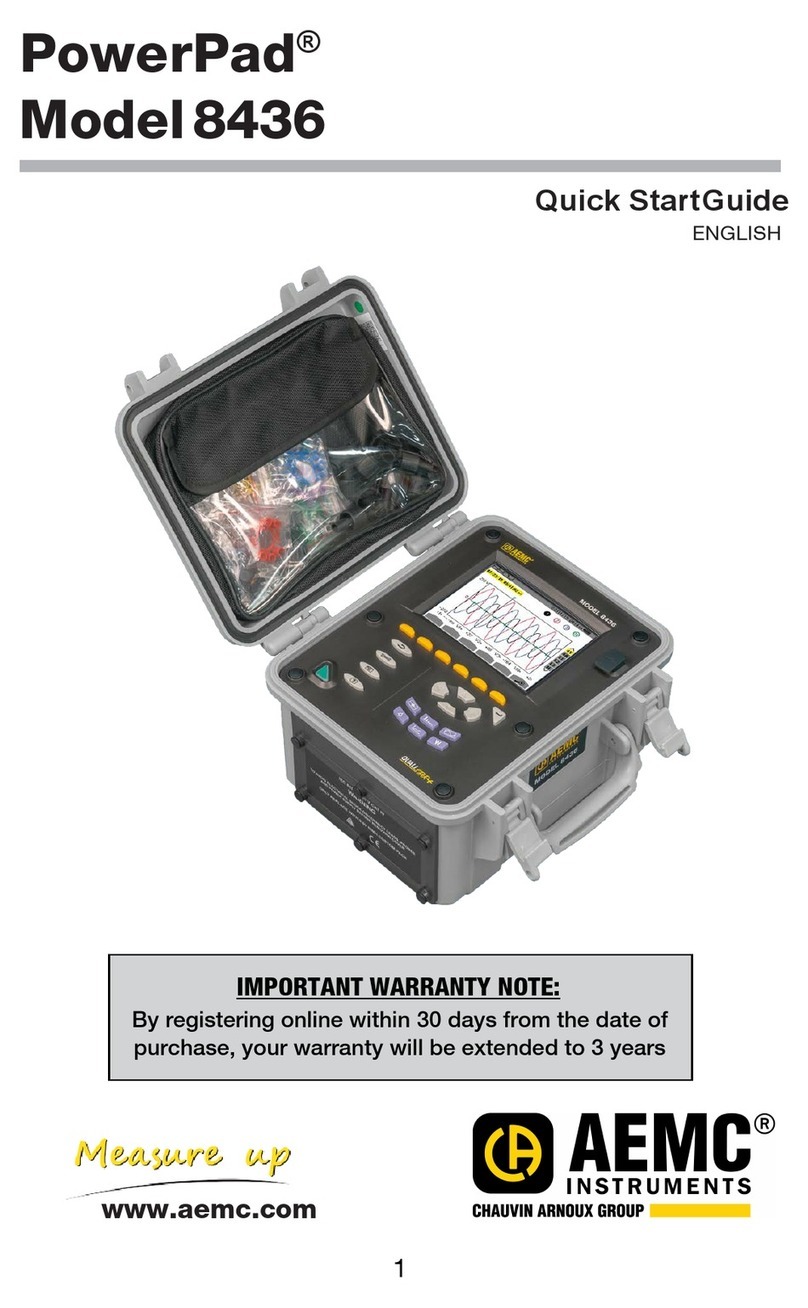

“WATTS CURRENT” TECHNICAL BULLETIN

3. To edit an alarm field, highlight it using the up and down arrow buttons, then confirm the

selection by pressing .

4. To activate an alarm, highlight its number in

the left-most column and press . A red dot

indicates the alarm is active. The other fields

(left to right) are as follows:

•Type (42 types of alarms can be configured)

•Harmonic order (for alarms that include

harmonics data)

•Target (4L, 3L, N, Σ)

•Direction (> or <)

•Trigger threshold

•Trigger delay

•Hysteresis

(see Sidebar)

The Alarm Mode screen consists of 8 pages,

each listing 5 alarms. Use the and

buttons to browse through the pages.

5. When you finish changing alarm settings, press

to return to the Detection Schedule screen

(see Step 1 above). This screen displays three

input fields:

•Start defines the time and date when the

recording starts.

•Stop specifies when the recording ends.

•Name allows you to name the test. This

can be 8 characters long.

6. Use the arrow and buttons to highlight,

select, and edit the Start, Stop, and Name

fields.

7. Press the button to write the settings to

the instrument.

8. If not enough memory is available, an error

message appears informing you of this.

Otherwise, the alarm detection session will begin at the scheduled start time and date. If a

session is scheduled but not yet started, the message DETECTION ON STANDBY

appears on the screen until the start time is reached, at which point the message changes

to DETECTION IN PROGRESS.

On PowerPad III instruments,

hysteresis defines a “lag” in alarm

deactivation. To understand how this

works, consider a “

” alarm with no

hysteresis. The instant the trigger

threshold is exceeded the alarm

activates, and deactivates the instant

the measurement falls below the

threshold. In this situation, multiple

alarms may be recorded if the

measurement is very close to the

threshold – each time the measurement

fluctuates slightly above and below the

trigger, a separate alarm is reported.

This can result in multiple alarms being

detected for a single spike event.

Hysteresis filters out these alarms by

introducing a measurement lag into the

process. In our example, if we set

hysteresis to 5%, an alarm will remain

active until the measurement falls 5%

below the trigger threshold. This also

applies to

alarms: if the threshold is

passed, the alarm remains active until

the measurement exceeds the

threshold by the hysteresis percentage.

By adjusting hysteresis, we can control

the sensitivity of the alarm trigger. If

your recording session results in a high

number of alarms, you can set

hysteresis higher. If the recording

captures few alarms, you can lower the

setting to ensure actual fast, short-lived

events are not being missed.